Break-resistant optical cable

An anti-break, optical cable technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems affecting the long-term stability of optical fiber transmission characteristics, optical fiber bending or breaking, optical signal transmission interruption, etc., to reduce attenuation and maintain good linearity. , reduce the effect of additional attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

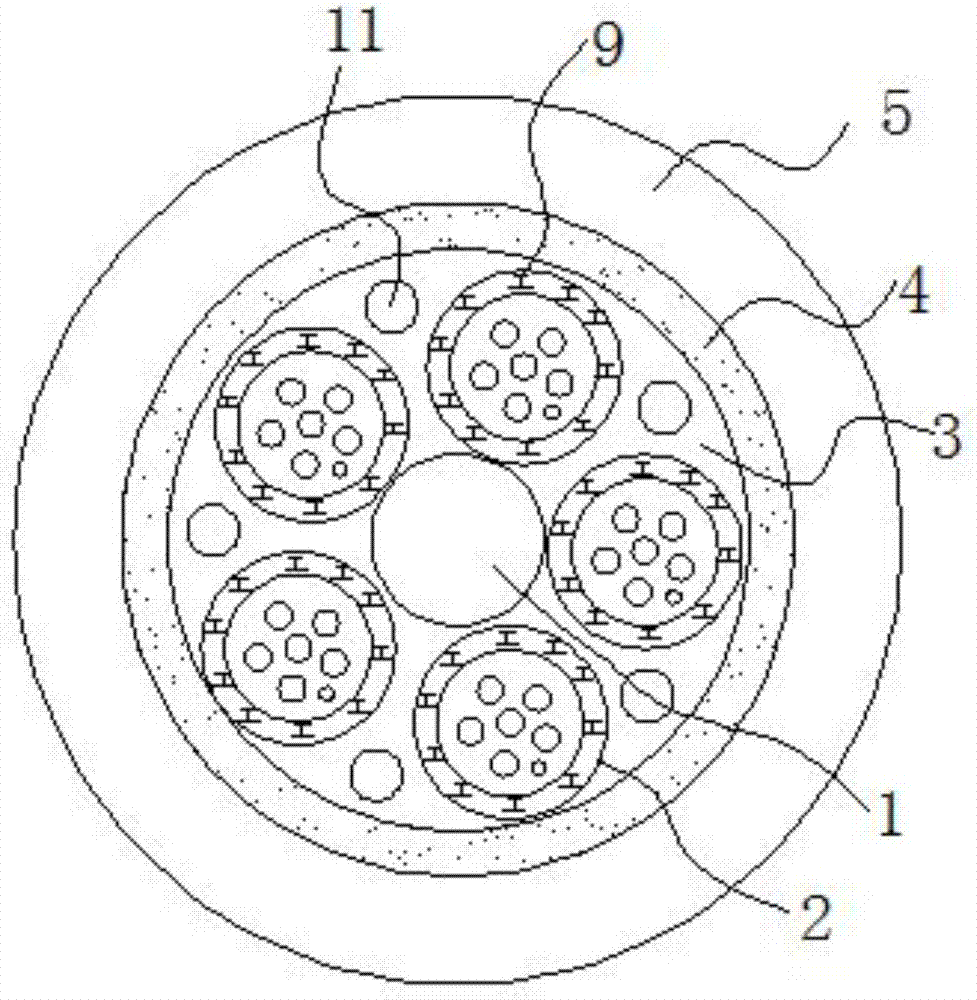

[0027] Example: see figure 1 with figure 2 , a breakage-resistant optical cable, comprising a reinforcing core 1, a cable core 2, a cable core filler 3, a coated aluminum tape 4 and a polyethylene sheath 5, and the cable core is centered on the reinforcing core and uniformly laid on the The outer periphery of the reinforcing core, the coated aluminum strip wraps the cable core, and the spaces between the reinforcing core and the cable core and between the cable core and the coated aluminum strip are filled with The cable core filler, the polyethylene sheath covers the coated aluminum strip;

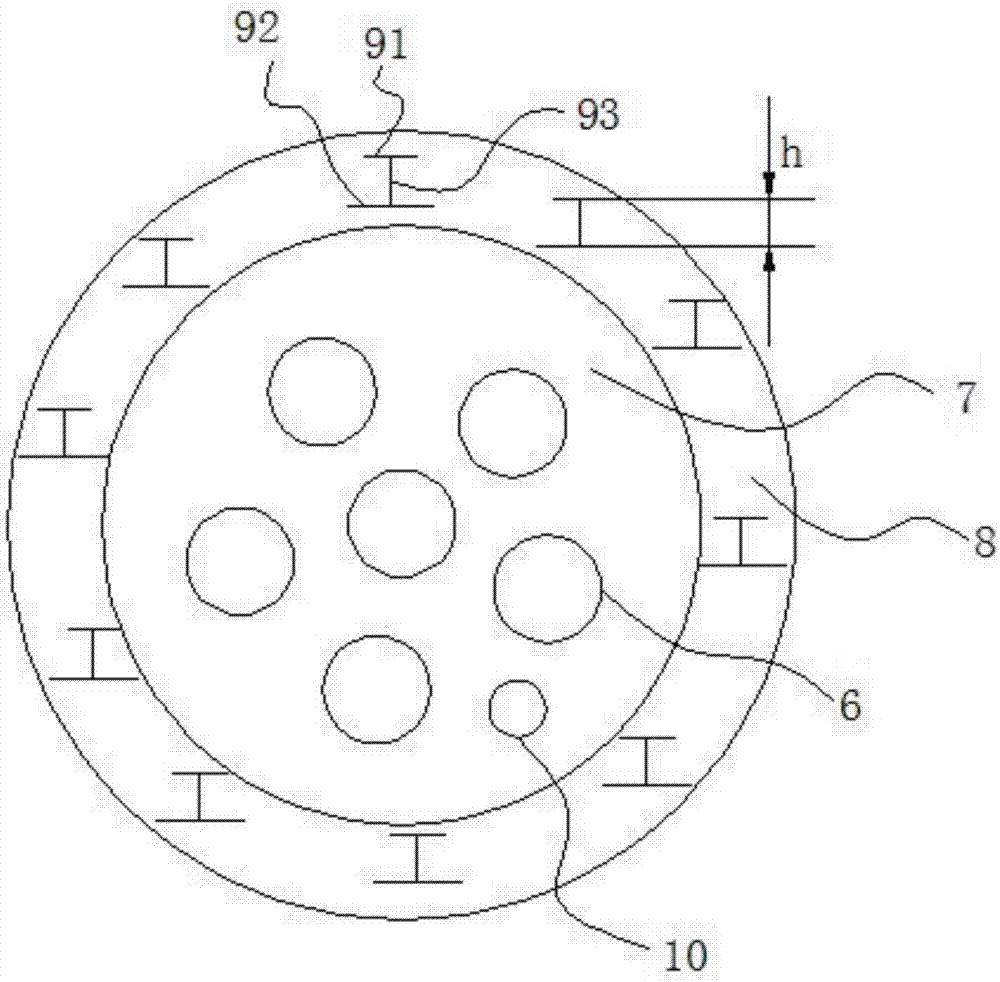

[0028] The cable core includes an optical fiber 6, a sleeve filler 7 and a loose tube 8, the loose tube covers the optical fiber, and the gap between the optical fiber and the loose tube is filled with the sleeve filler;

[0029] The loose tube is embedded with a plurality of "I" shaped reinforcing ribs 9, the height h of the ribs is 2 / 3-3 / 4 times the thickness of the loose tube, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com