Conveying device

A technology for conveying devices and conveyor belts, which is applied in signal transmission systems, instruments, computer control, etc., and can solve problems such as increased equipment and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] For the detailed description and technical content of the present invention, please refer to the following detailed description and accompanying drawings as follows, and the accompanying drawings and detailed description are for illustration purposes only, and are not intended to limit the present invention.

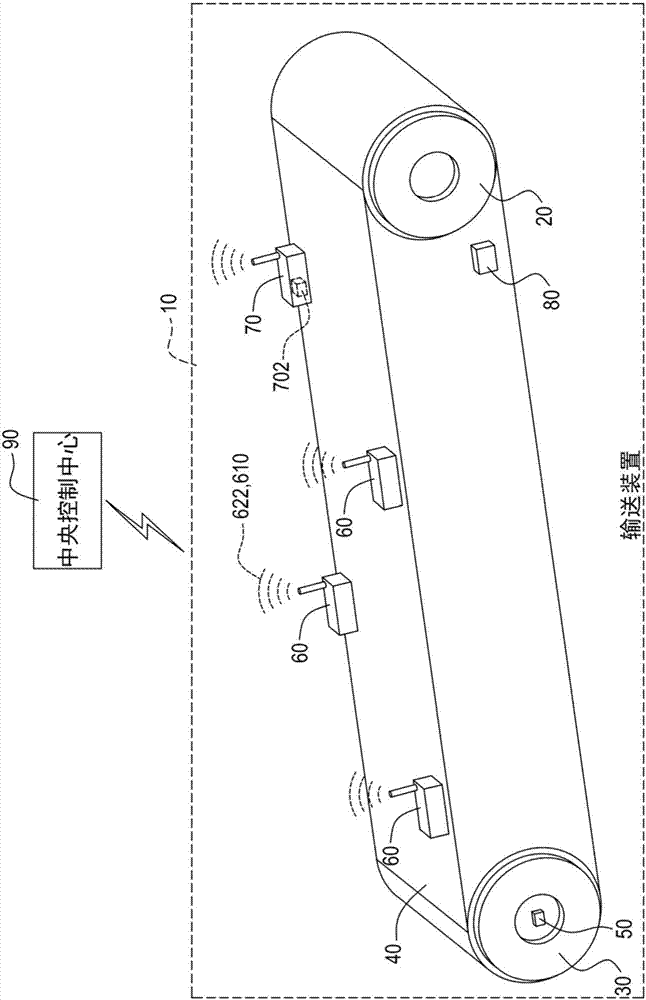

[0057] Please refer to figure 1 , which is a schematic diagram of the delivery device of the present invention. The conveying device 10 of the present invention includes a power main shaft 20, an idler main shaft 30, a conveyor belt 40, a function / energy conversion wireless monitoring device 50, at least one field wireless controller 60, at least one cassette 70 and a stop The conveyor operates the switch 80 .

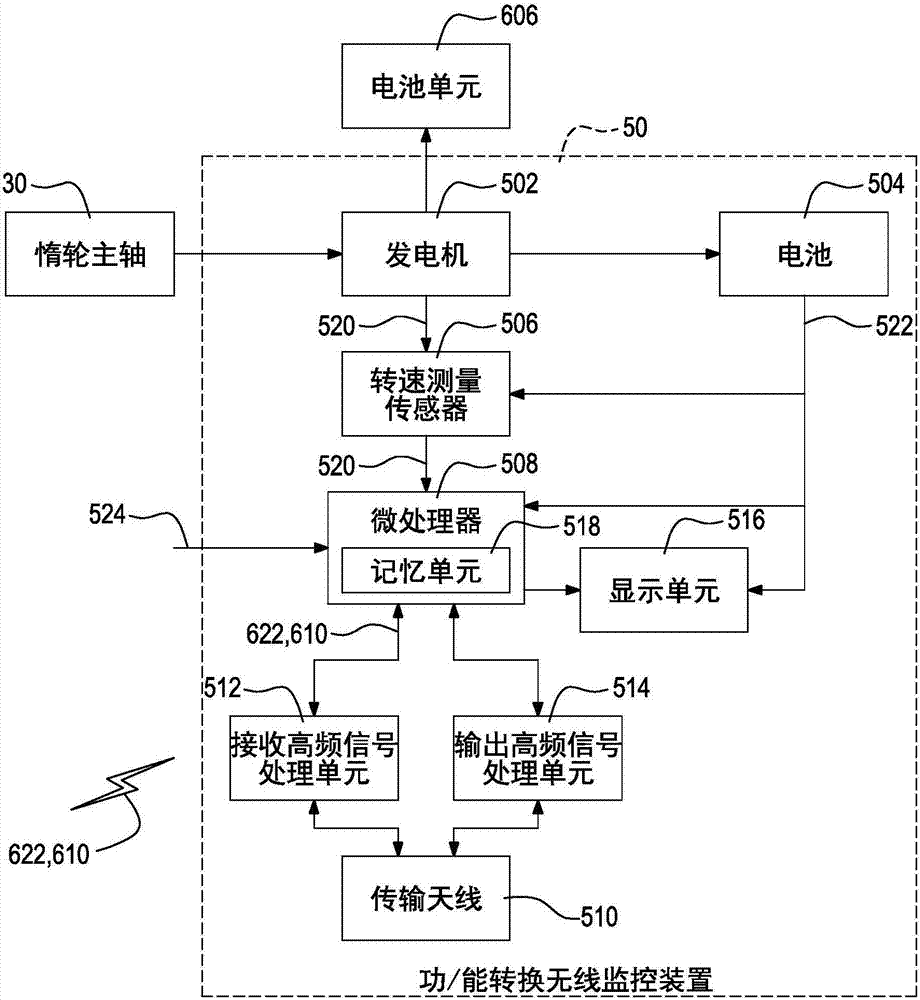

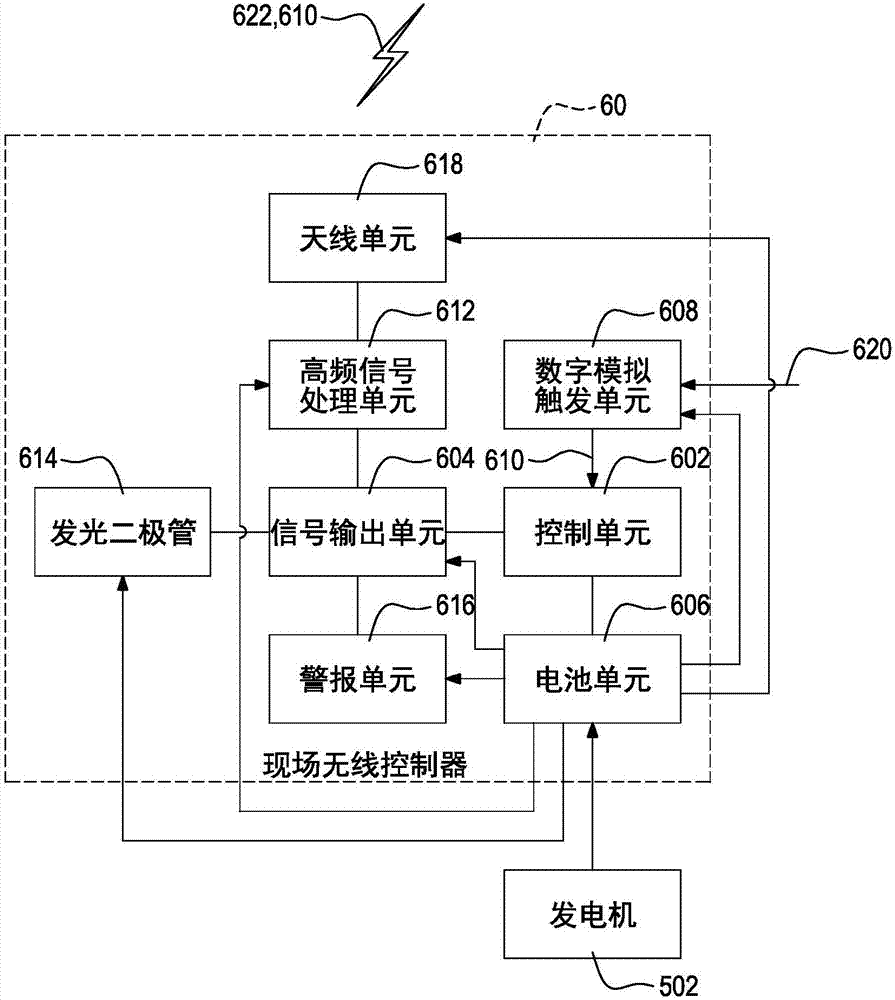

[0058] The conveyor belt 40 is connected to the power main shaft 20 and the idler main shaft 30, so that when the power main shaft 20 rotates, the power main shaft 20 can drive the idler main shaft 30 through the conveyor belt 40; the function / function co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com