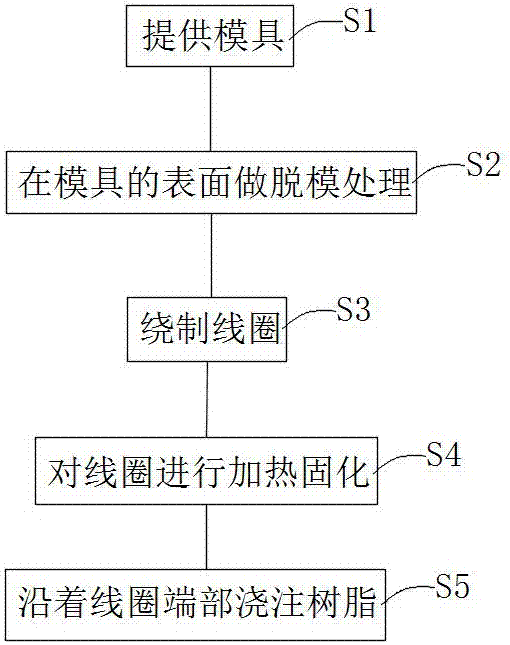

Winding process for foil type coil

A coil and process technology, applied in the field of foil coil winding process, can solve the problems of limited production efficiency, difficult demoulding, complex casting mold structure, etc., achieve enhanced mechanical strength and insulation strength, and solve low manufacturing efficiency and fast The effect of mold loading and demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

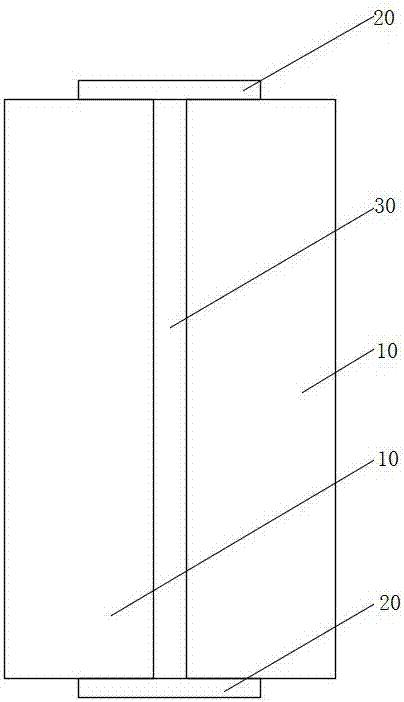

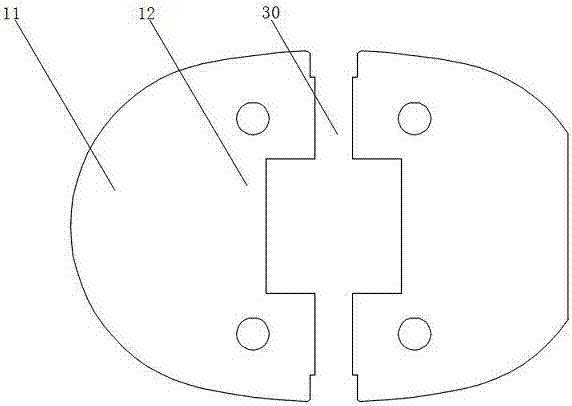

[0027] Step S1, provide mould, described mold comprises two semicircular mold cylinders 10 and positioning plate 20, the two ends of two described semicircular mold cylinders 10 are respectively provided with positioning plate 20, and described positioning plate 20 is two described semicircular For the fixed connection of the mold cylinders 10, the two semicircular mold cylinders 10 are arranged facing each other, and a gap 30 is left between the two semicircular mold cylinders 10.

[0028] The mold provided in this step is an inner mold, and an outer mold for encapsulation is not needed, thereby saving mold cost. The two semicircular mold cylinders 10 are fixed by using two semicircular mold cylinders 10 provided with gaps 30 and by positioning plates 20 . When the mold needs to be disassembled, the positioning plate 20 is removed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com