System for flushing pipe plumbing using microbubbles, method therefor, and ship or maritime plant having same

A flushing system and pipe system technology, which is applied in the field of pipe flushing systems using ultra-fine foam, can solve problems such as incomplete removal of scale in pipe sections, damage to filters or water filters, inability to completely remove scale, etc., to achieve extended Effects of life and efficiency, increase of Reynolds number, and maximization of process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings.

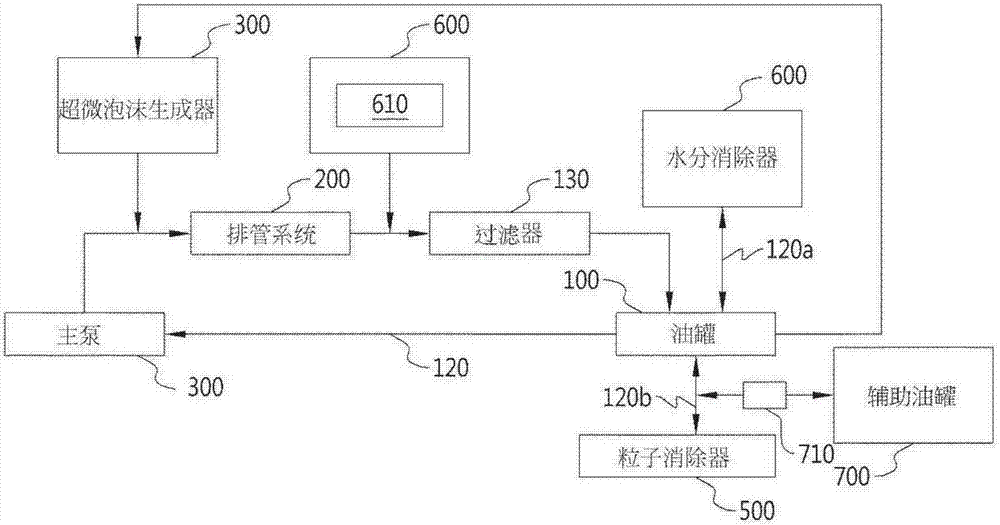

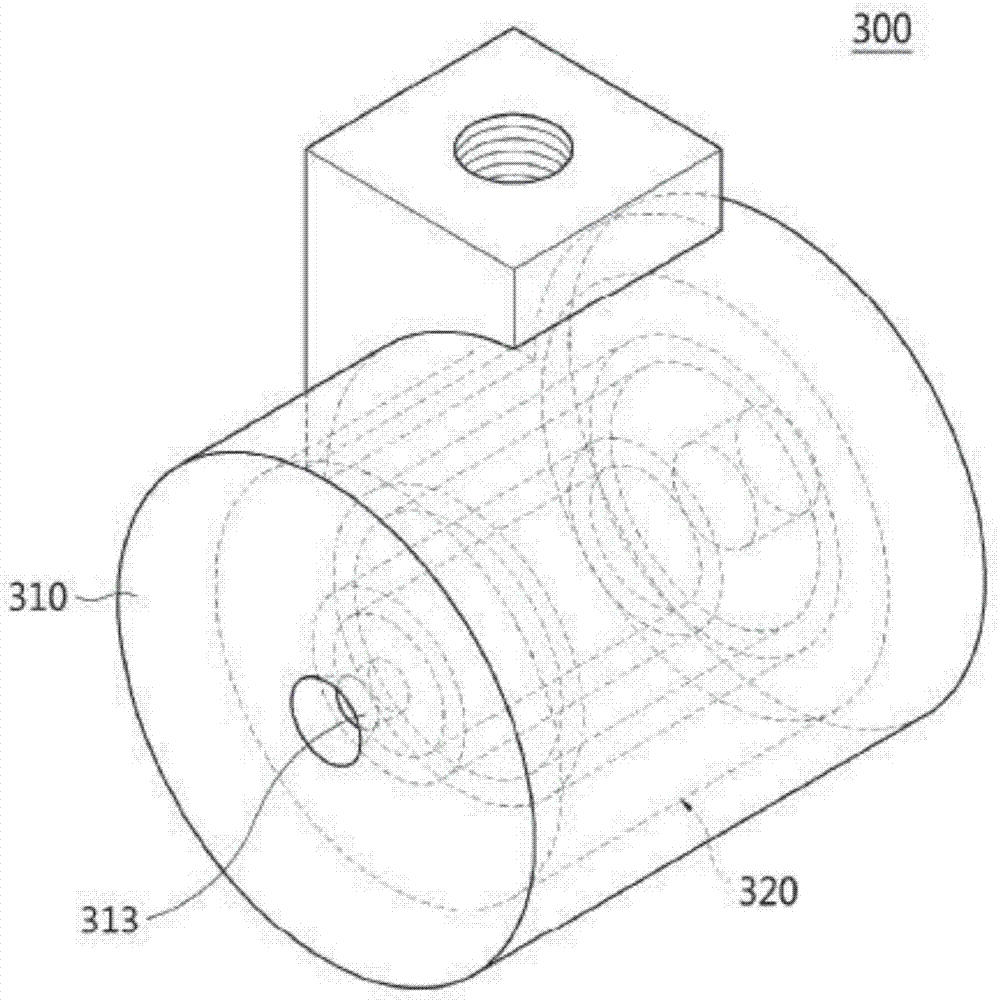

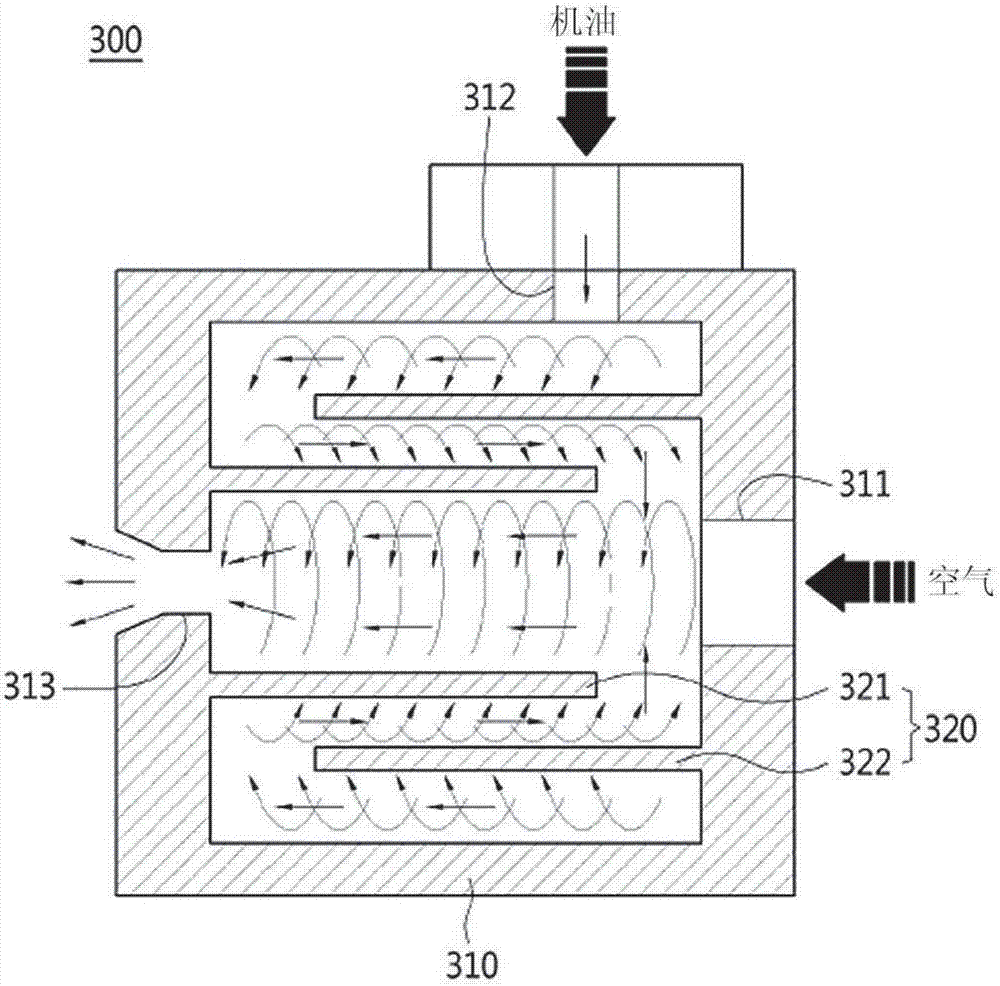

[0070] figure 1 It is a flow chart representing the pipe flushing system according to the present invention; figure 2 It is an internal projection perspective view of the ultra-fine bubble soo generator of the pipe flushing system according to the present invention; image 3 for figure 2 sectional view of Figure 4 It is a structural diagram showing the moisture eliminator of the drainage pipe flushing system according to the present invention; Figure 5 It is a diagram showing the internal structure of the particle eliminator of the pipe flushing system according to the present invention; Image 6 to express the basis Figure 5 Cross-sectional view of the electrode of the particle eliminator.

[0071] Figure 7 It is a block diagram representing a pipe flushing method according to the present invention; Figure 8 It is a block diagram representing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com