Steel storage device

A type steel and loading technology, which is applied in the direction of object stacking, loading/unloading, transportation and packaging, etc., can solve the problems of complex device structure, large equipment scale, and increased cost, so as to improve operation efficiency and facilitate operation sequence , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Hereinafter, examples of the present invention will be described, but the present invention is not limited to the following examples, and can be implemented with appropriate changes within the scope of the gist of the invention.

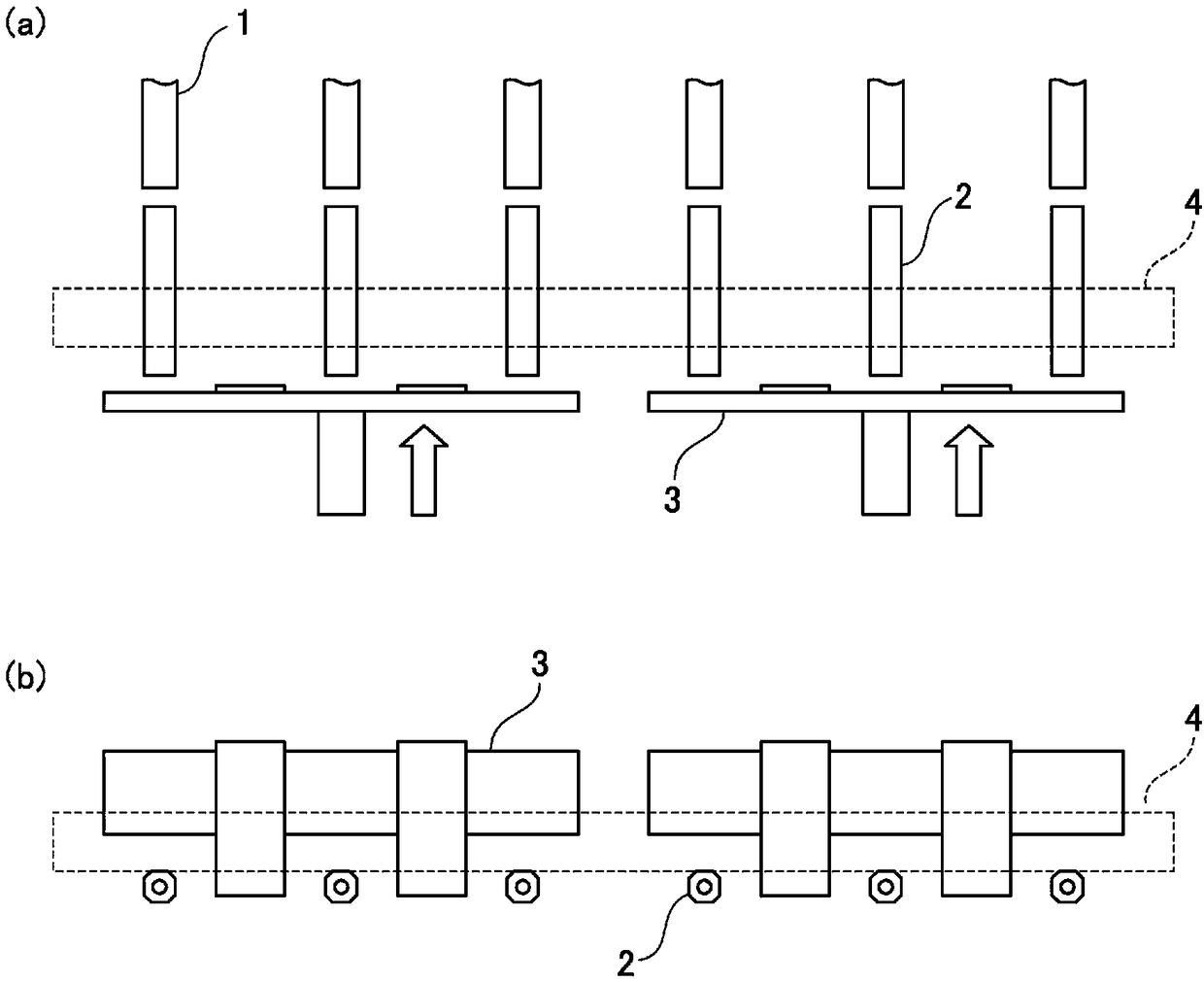

[0049] figure 1 A specific example of the storage device of the present invention is shown. Shown is the equipment provided with two stacking devices, the stacking device is equipped with three rotating belts (stacking platform 1), stacking rollers (conveying platform 2), and a pusher (extrusion mechanism 3). ). The pusher is provided with a plate-shaped member that can pass between the transfer tables. The H-shaped steel 4 is carried in from the storage place (not shown) to the transfer table 2, straddles the transfer table 2 of the two storage devices, and stands by.

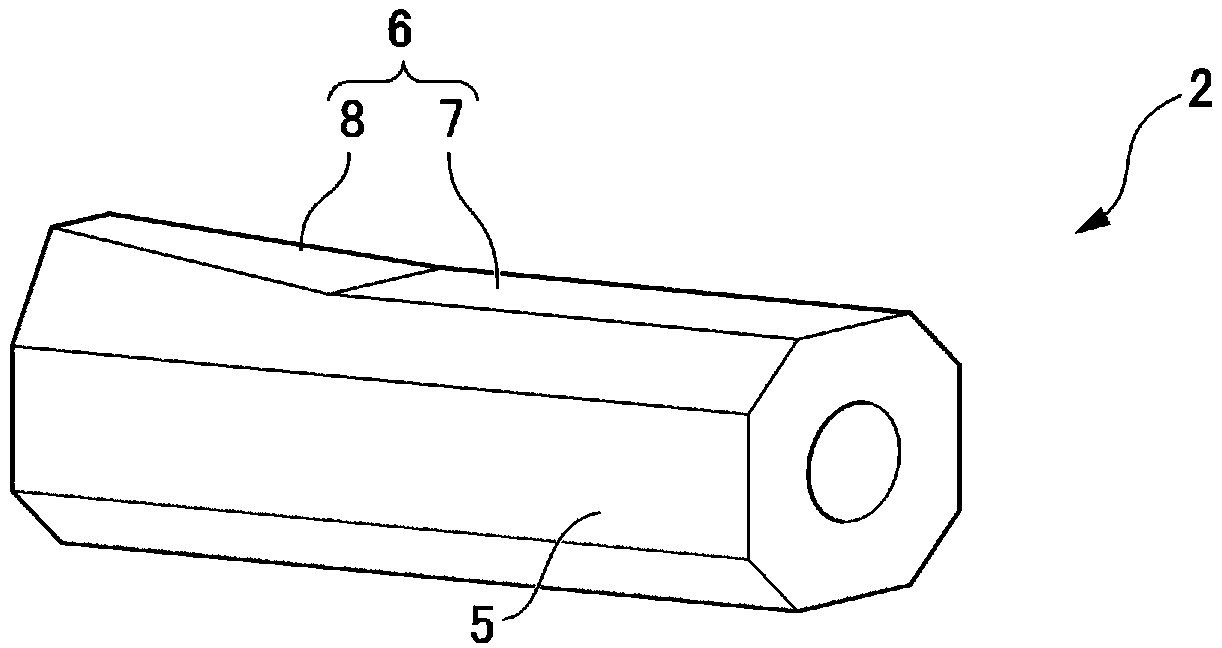

[0050] figure 2 It is a schematic diagram which shows the specific example of the transfer table 2 of this invention. The transfer table 2 has a prism shape having a cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com