Device for crimping a tow

A technology for crimping and tow, which is applied in the field of devices for crimping and deforming tow, and can solve problems such as damage to the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

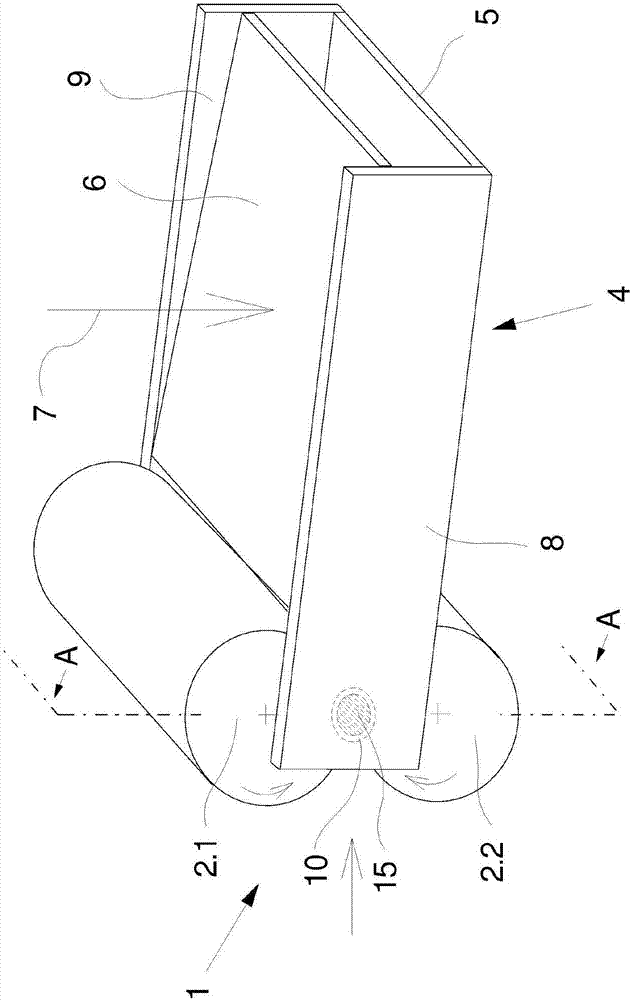

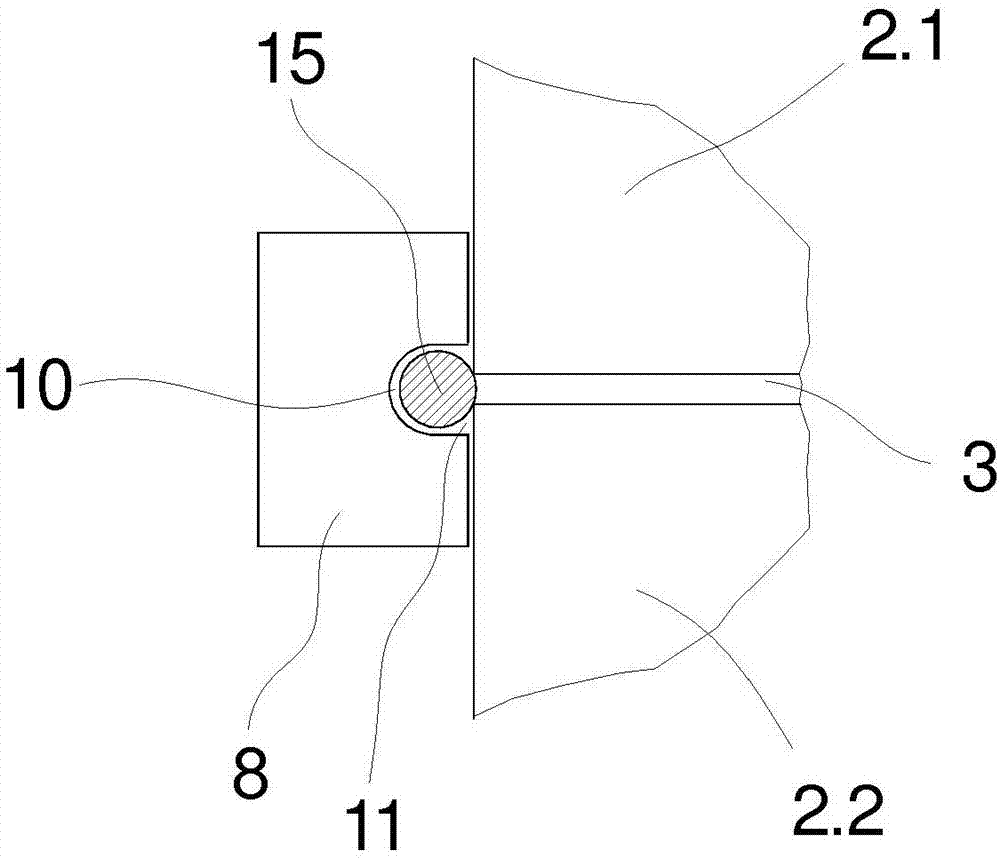

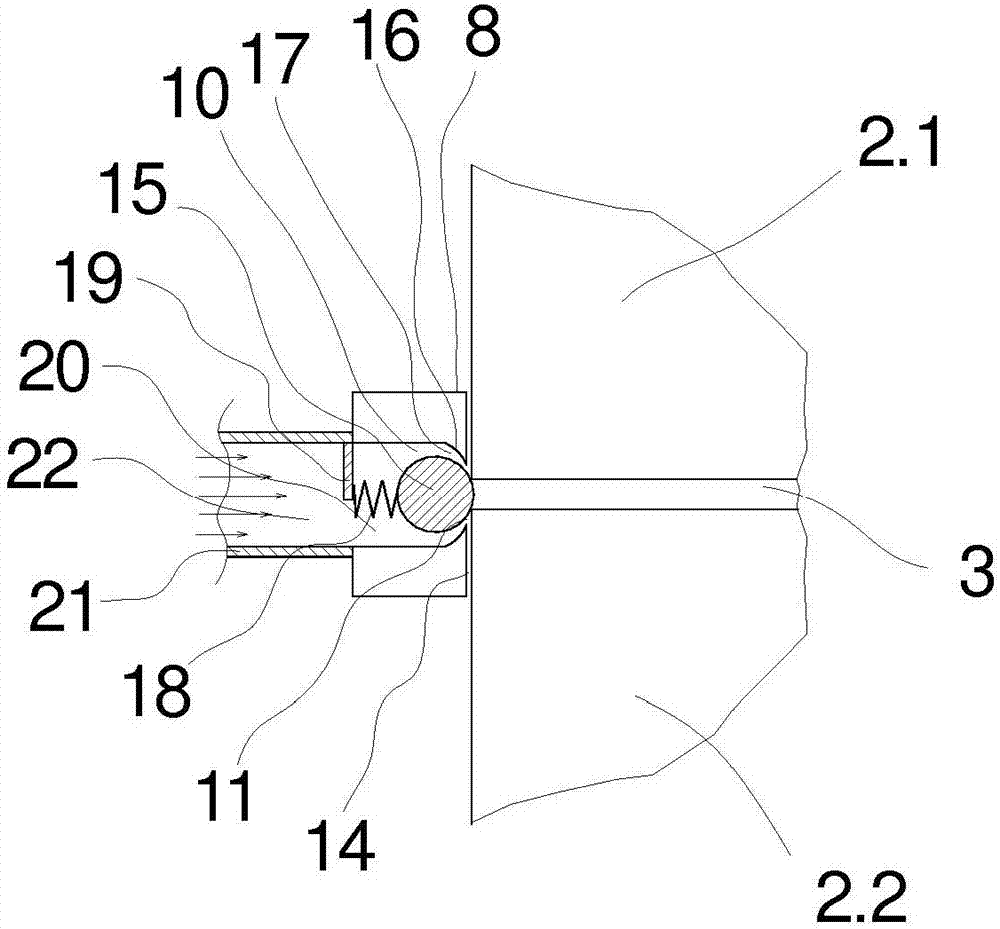

[0020] figure 1 Shown here is a texturing machine 1 consisting of two texturing rolls 2.1 and 2.2 and a stuffer box 4. FIG. The stuffer box 4 is defined on the periphery by side panels 8 and 9 , a bottom panel 5 , and a cover panel 6 . The base plate 5 is fixedly connected to the side plates 8 and 9 . The cover plate 6 is pivotable about a horizontal axis due to the capping force shown symbolically by the arrow. Arranged at the inlet of the stuffer box 4 are two texturing rollers 2.1 and 2.2, which can be driven in the direction of rotation indicated by the arrow by a motor, not shown. The end faces of the texturing rollers 2.1 and 2.2 extend until they abut against the side plates 8 and 9. The axes of the texturing rollers 2.1 and 2.2 are arranged horizontally and with a distance parallel to each other, so that a narrow texturing gap 3 is created between the texturing rollers 2.1 and 2.2, through which the tow to be treated consisting of a monofilament sliver passes. It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com