Flexible Surface Area Light, In Particular For Use In A Piece Of Clothing

A flexible surface and light source technology, applied in the field of flexible surface light sources, can solve problems such as large thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

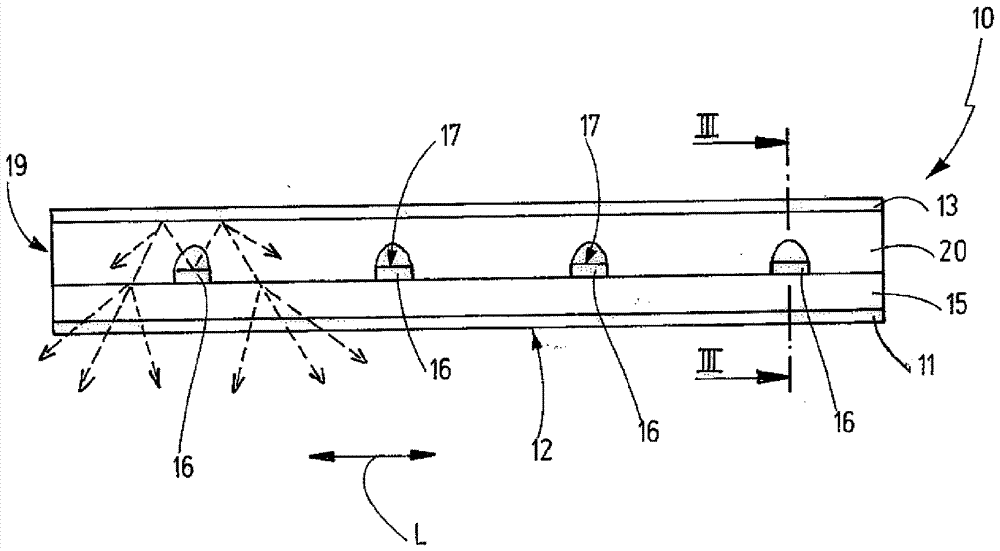

[0032] in Figure 1 to 3 The first embodiment of the flexible surface light source 10 is shown in FIG. The flexible surface light source 10 has a transparent covering layer 11. There is a light exit surface 12 at the transparent cover layer 11, and the light of the surface light source 10 exits at the light exit surface. The covering layer 11 is at least transparent to the light wave length spectrum or light wave length that should be emitted from the surface light source 10, for example, white light or light of a certain color.

[0033] The surface light source 10 has a reflective layer 13 with a reflective surface 14 on the side opposite to the covering layer 11. The reflective surface 14 faces the covering layer 11. No light can pass through the reflective layer 13 and leave. The light incident on the reflecting surface 14 is completely reflected.

[0034] A first scattering layer 15 is optionally attached to the cover layer 11 on the side opposite to the light exit surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com