Optimizing method for lithography machine mask

An optimization method and technology of lithography machines, applied in the field of lithography machines, can solve the problems of reduced manufacturability of masks, lack of orientation of crossover and mutation operations of genetic algorithms, and weak approximation ability of optimal solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the examples and drawings, but the examples should not limit the protection scope of the present invention.

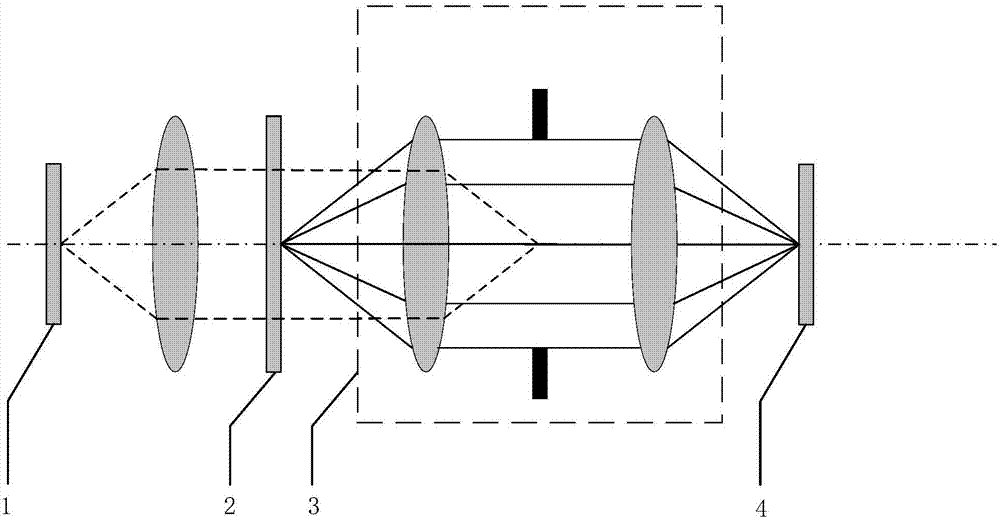

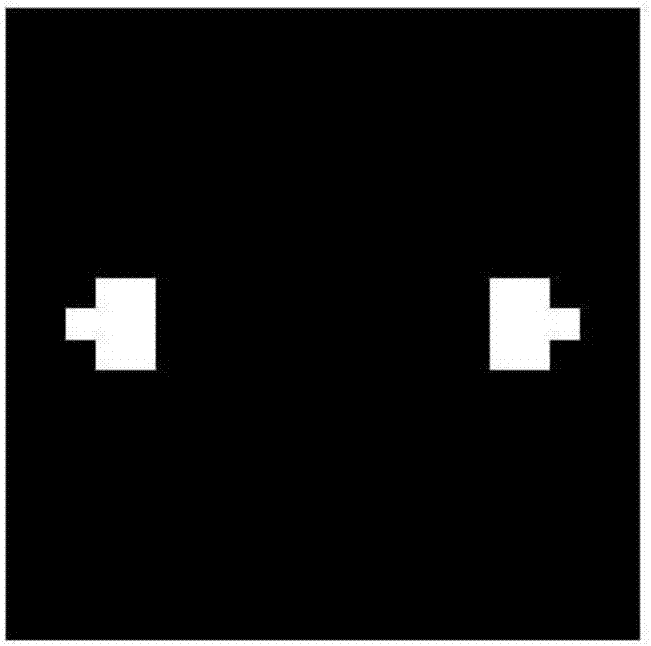

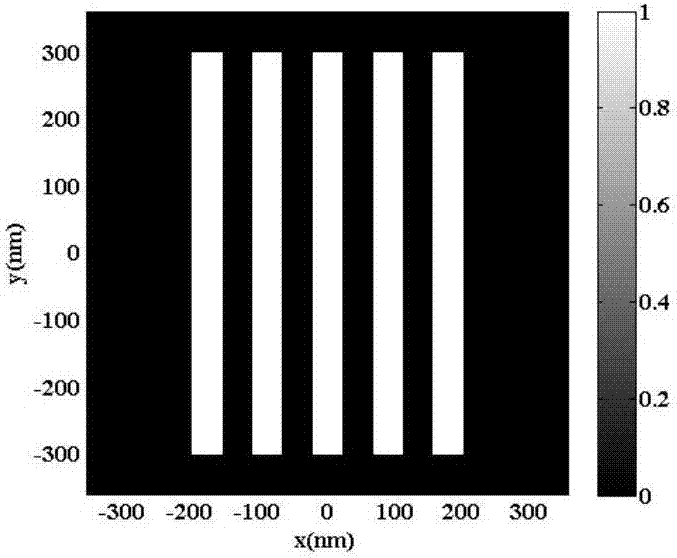

[0062] see first Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the lithography machine system used in the present invention. It can be seen from the figure that the method involves a light source 1 for the lighting system of the lithography machine, a mask 2, a projection objective lens 3, and a silicon wafer 4. figure 2 It is a schematic diagram of the lighting mode of the light source used in the present invention. The initial lighting mode of the light source is dipole lighting, the internal coherence factor is 0.6, the external coherence factor is 0.8, the size is 21×21 pixels, and the brightness value of the white area is 1. The brightness value of the black area is 0. image 3 It is a schematic diagram of the initial mask pattern used in the present invention. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com