Improved manufacturing for virtual and augmented reality systems and components

A diffractive optical element and pattern technology, applied in optical elements, optical elements, instruments, etc., can solve the problems of eye fatigue, unstable imaging, adaptability conflict of human visual system, etc., achieve a uniform base layer, and increase the output angle of the grating , the effect of increasing the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

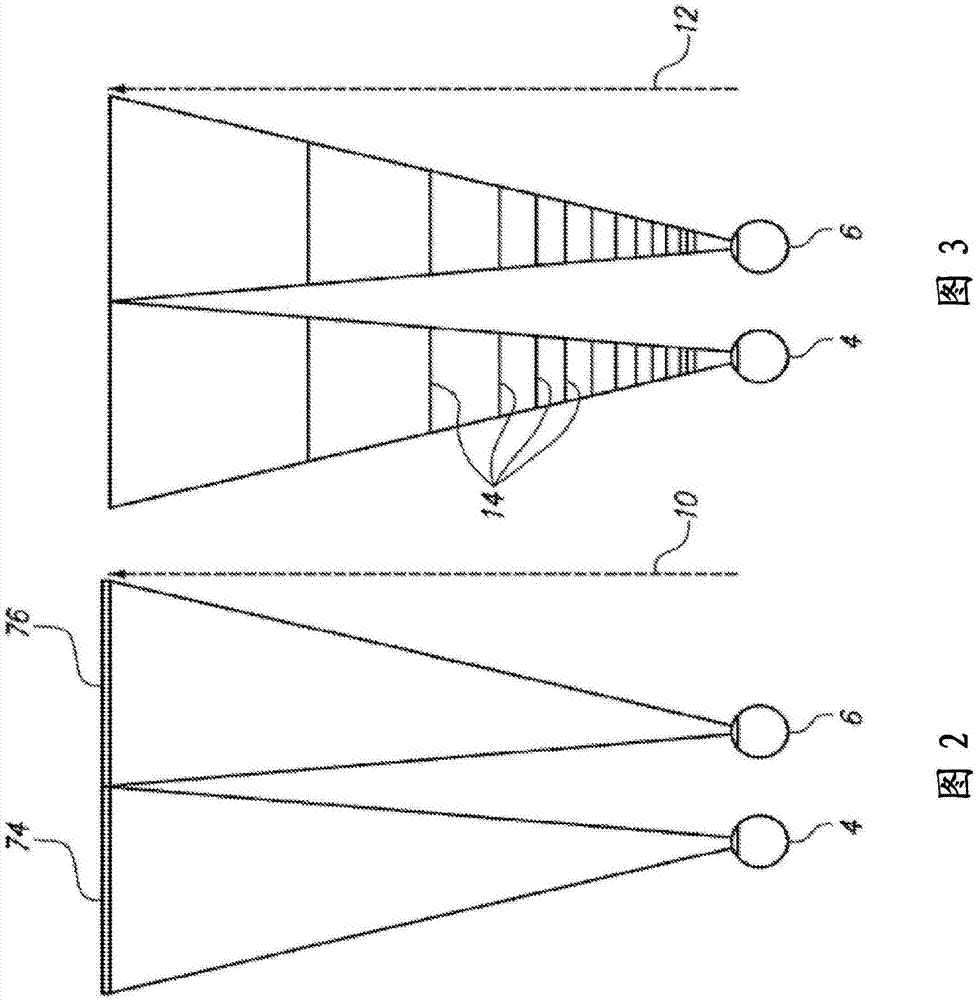

[0048] According to some embodiments of the present invention, a diffractive structure including an underlayer / intermediate layer between the waveguide substrate and the top grating surface is adopted. The top grating surface includes a first material corresponding to a first refractive index value, the underlying layer includes a second material corresponding to a second refractive index value, and the substrate includes a third refractive index value The third material.

[0049] One advantage of this method is that the appropriate choice of the relative refractive index of the three layers allows the structure to obtain a larger field of view for a larger range of incident light, because the lowest total internal reflection angle increases with the refractive index. Big and reduce. The diffraction efficiency can be increased, allowing "brighter" light to be output to the display of the image viewing device.

[0050] Various combinations can be used, in which an underlying layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com