A sleeve-type fully flexible robotic arm driven by layers

A robotic arm, fully flexible technology, applied in the direction of robotic arms, claw arms, manufacturing tools, etc., can solve the problems of large space required and low flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings:

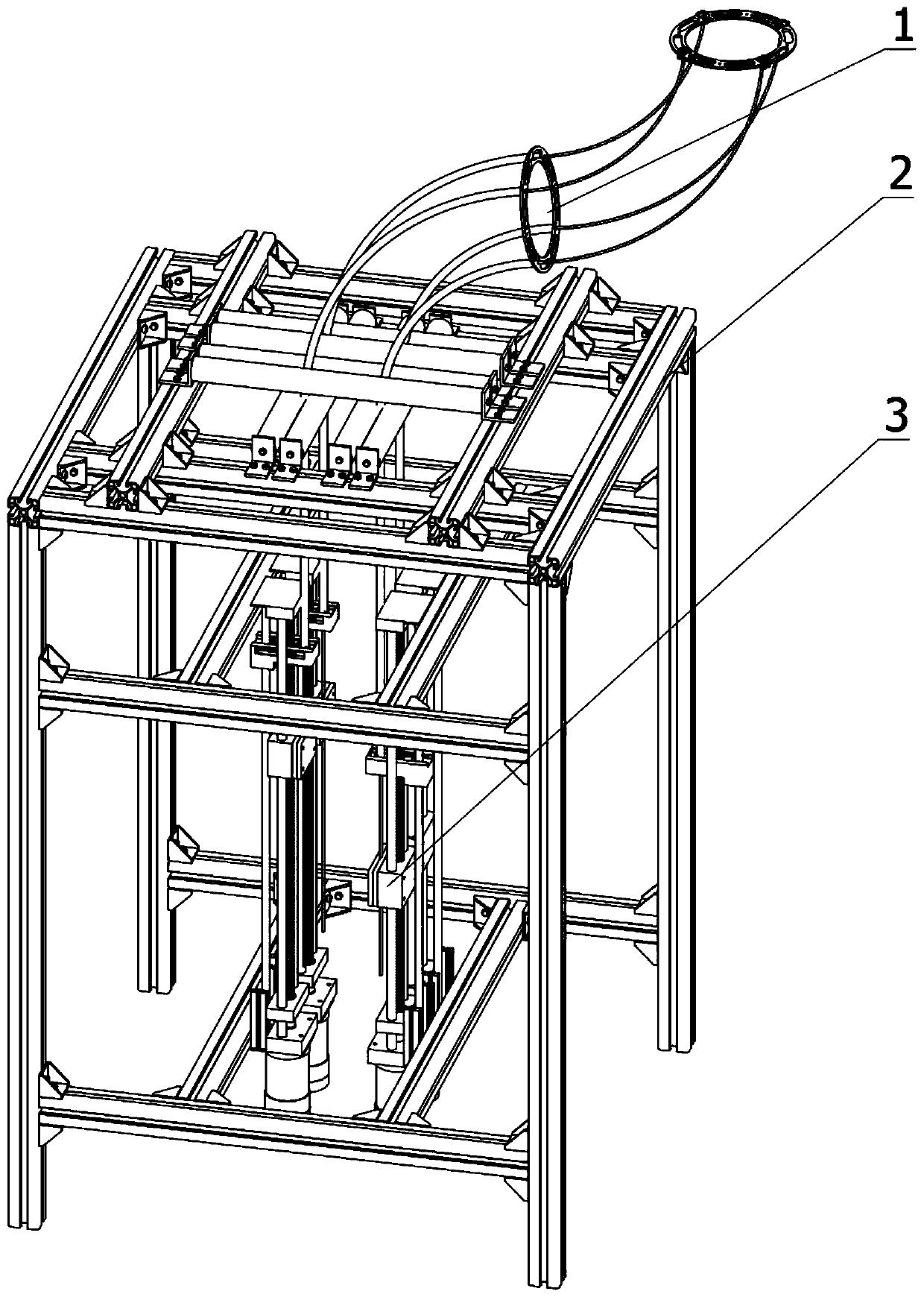

[0016] like figure 1 Shown is the extended posture of the flexible arm. A sleeve-type fully flexible mechanical arm driven by layers is composed of a telescopic flexible arm 1 , a frame 2 , and a slide rail 3 . Wherein, both the flexible arm 1 and the slide rail 3 are fixed on the frame 2 . There are 4 slide rails 3 in total, and they are symmetrically placed on the frame 2 in pairs.

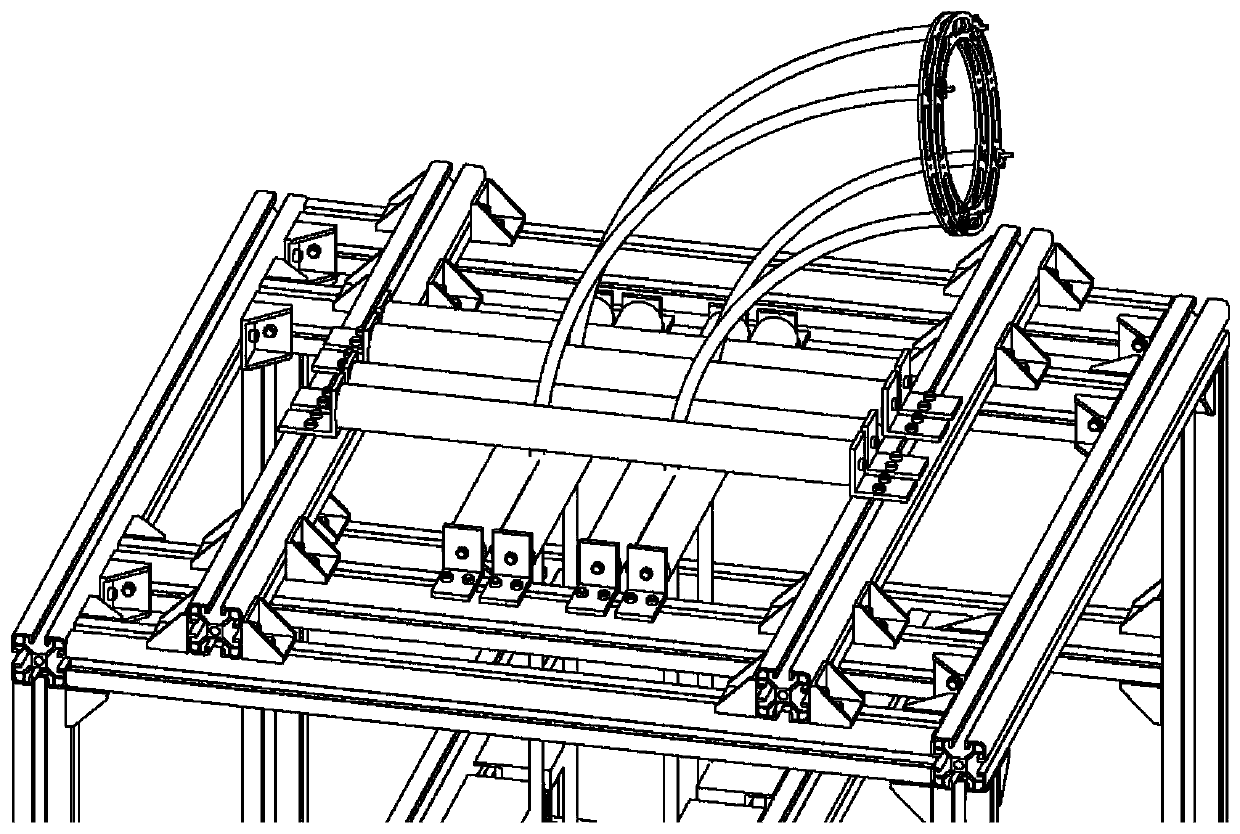

[0017] like figure 2 As shown, it is a semi-compressed state where the flexible arm stretches out from the rubber tube 1-5 and the glass fiber 1-3 does not stretch out.

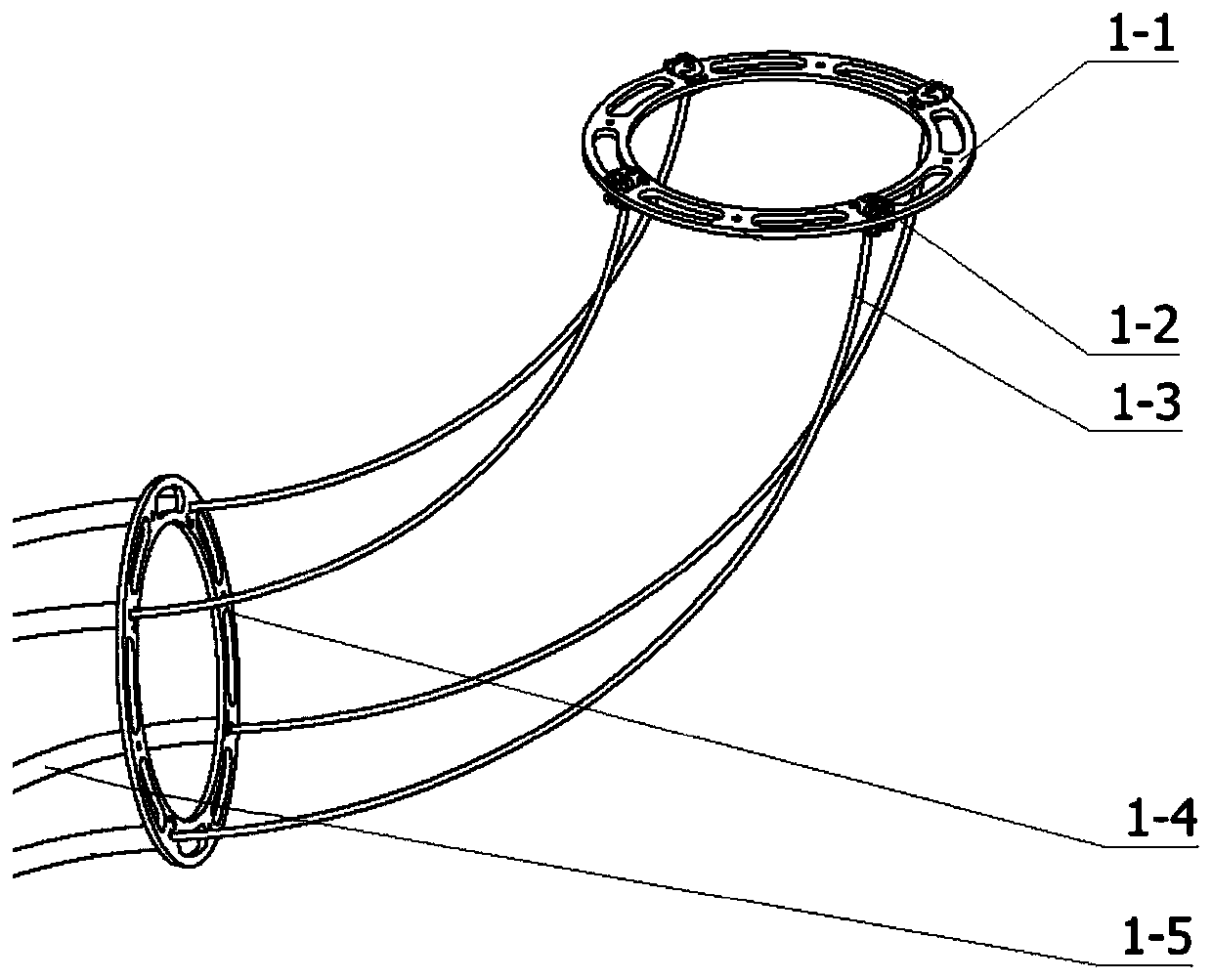

[0018] like image 3 As shown, the flexible arm 1 is composed of an end segment 1-1, a U-shaped card 1-2, a glass fiber 1-3, a middle segment 1-4, and a rubber sleeve 1-5. The end of each glass fiber 1-3 is locked on the end segment 1-1 by two U-shaped clips 1-2 at both ends of the end segment 1-1, and the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com