Grounding knife-switch operating mechanism

A technology of grounding switch and operating mechanism, applied in grounding switches, contact operating parts, high-voltage air circuit breakers, etc., can solve problems such as inability to use robots, improve the success rate of alignment and process execution efficiency, and avoid jamming , the effect of concentric improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

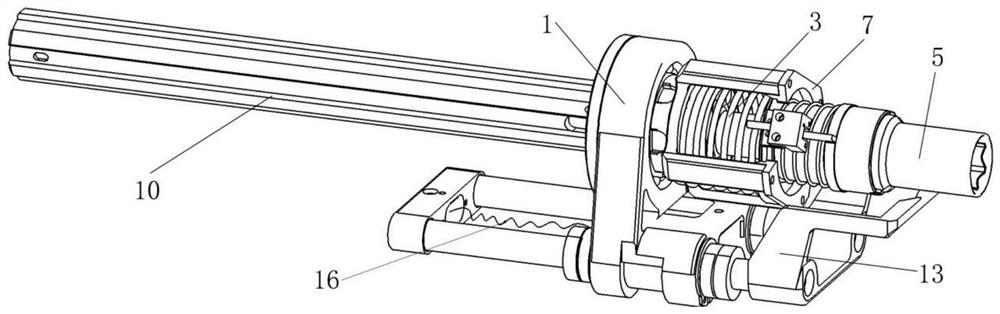

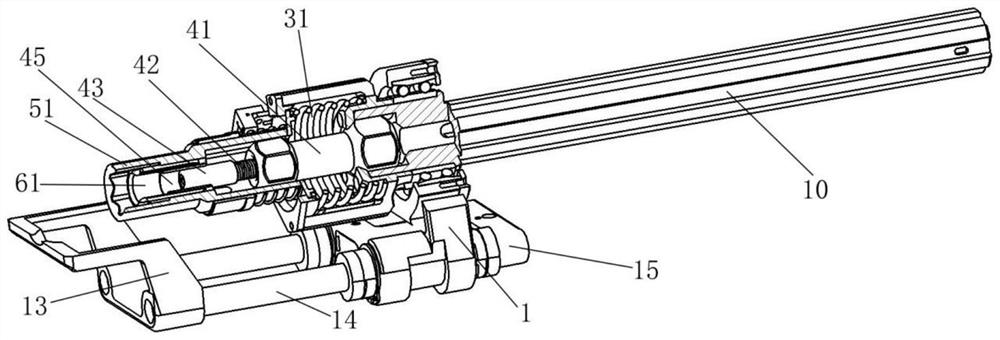

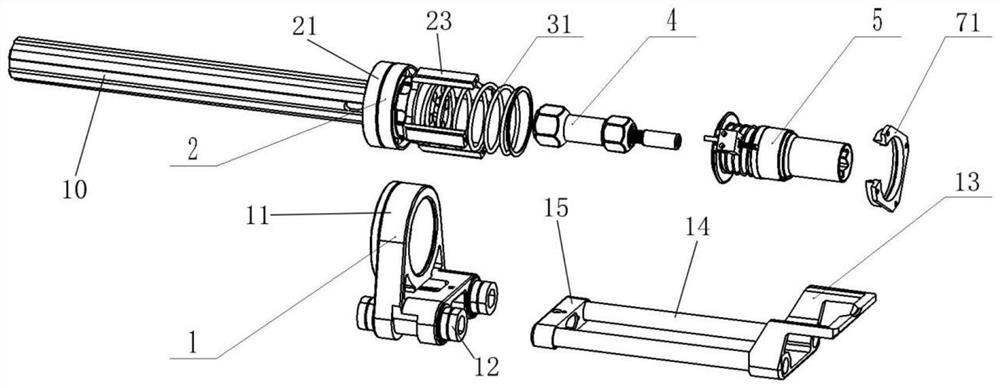

[0080] like figure 1 , 2 , 3, the grounding knife switch operating mechanism of this embodiment includes a telescopic pressure plate assembly 1, a mechanism bracket assembly 2, an adaptive assembly 3, a micro-view camera assembly 4, an operating head assembly 5 and an in-position detection assembly 6;

[0081] Among them, such as figure 2 , 3 As shown, the mechanism bracket assembly 2 includes a docking bracket (not shown in the figure) and a support rod 23, wherein the end surface of the docking bracket facing the grounding knife gate is provided with a hexagonal groove, and the other end surface of the docking bracket is docked with the robot transmission mechanism 10 through a flat key , and the telescopic and rotational degrees of freedom are provided by the robot-related transmission mechanism; at least three axially extending support rods 23 are evenly arranged in the circumferential direction of the end face of the docking bracket facing the grounding knife gate; in ...

Embodiment 2

[0098] like Figure 14 , 15 As shown, the grounding knife switch operating mechanism of this embodiment also includes a telescopic pressure plate assembly 1, a mechanism bracket assembly 2, an adaptive assembly 3, a micro-view camera assembly 4, an operation head assembly 5 and an in-position detection assembly 6, and wherein the telescopic pressure plate assembly 1 and the structure of the adaptive component 3 are the same as those of the first embodiment.

[0099] The mechanism bracket assembly 2 in this embodiment also includes a docking bracket, and the docking bracket is provided with a docking hole with a diameter larger than that of the robot transmission mechanism 10 passing through it; one end of the adaptive spring 31 of the adaptive assembly 3 is fixed by a spring spacer 32 Mounted on the docking bracket.

[0100] The micro-view camera assembly 4 of this embodiment also includes a fixing member 41 , a self-adjusting spring 42 , a camera rod 43 and a micro-view cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com