hc adsorption device

An adsorption device and power device technology, applied in the direction of charging system, fuel air filter, combustion air/combustion-air treatment, etc., can solve the problem of increasing intake resistance, increasing intake system intake resistance, adsorption Low efficiency and other problems to achieve the effect of avoiding air intake resistance, ensuring the use effect, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

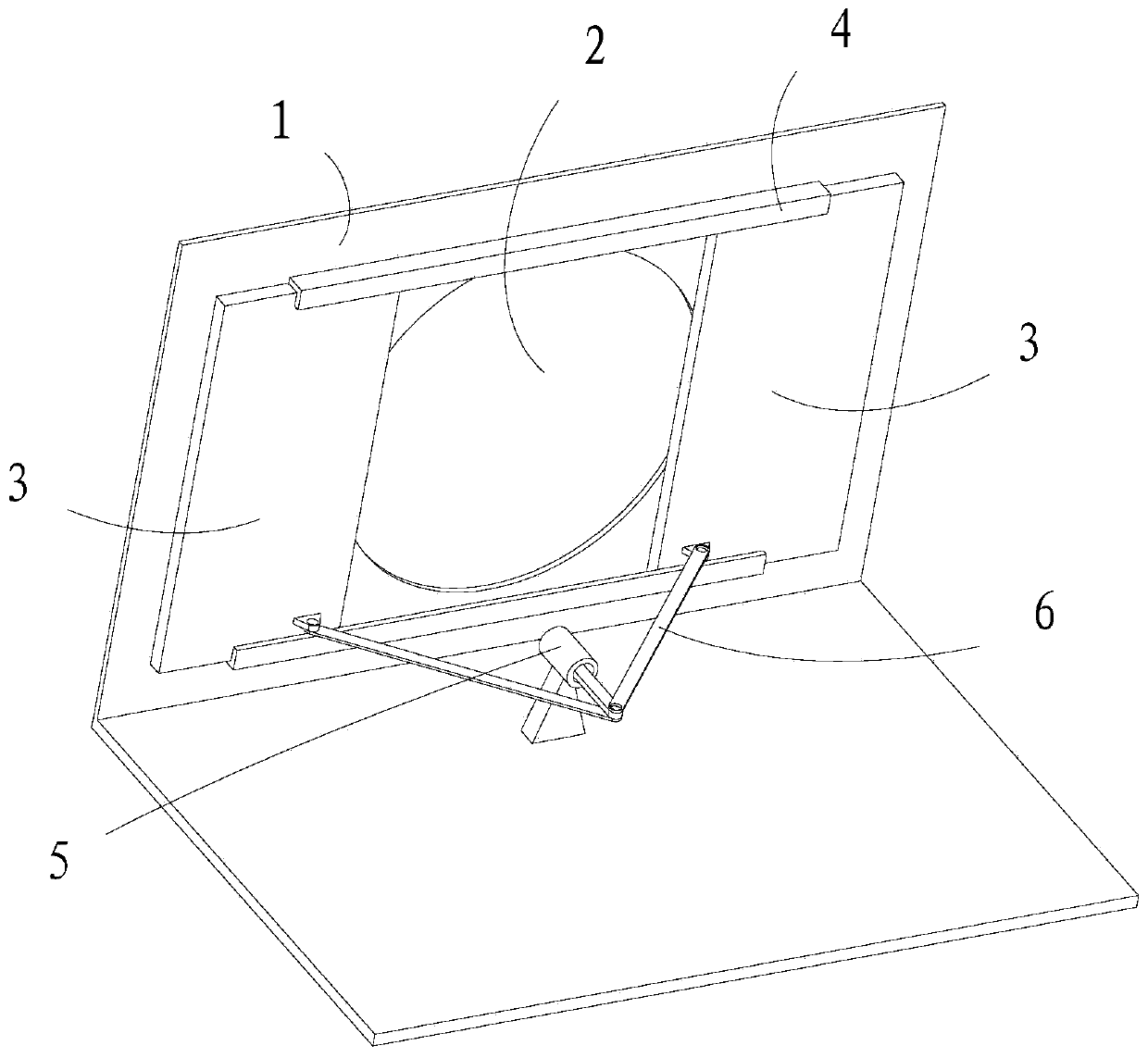

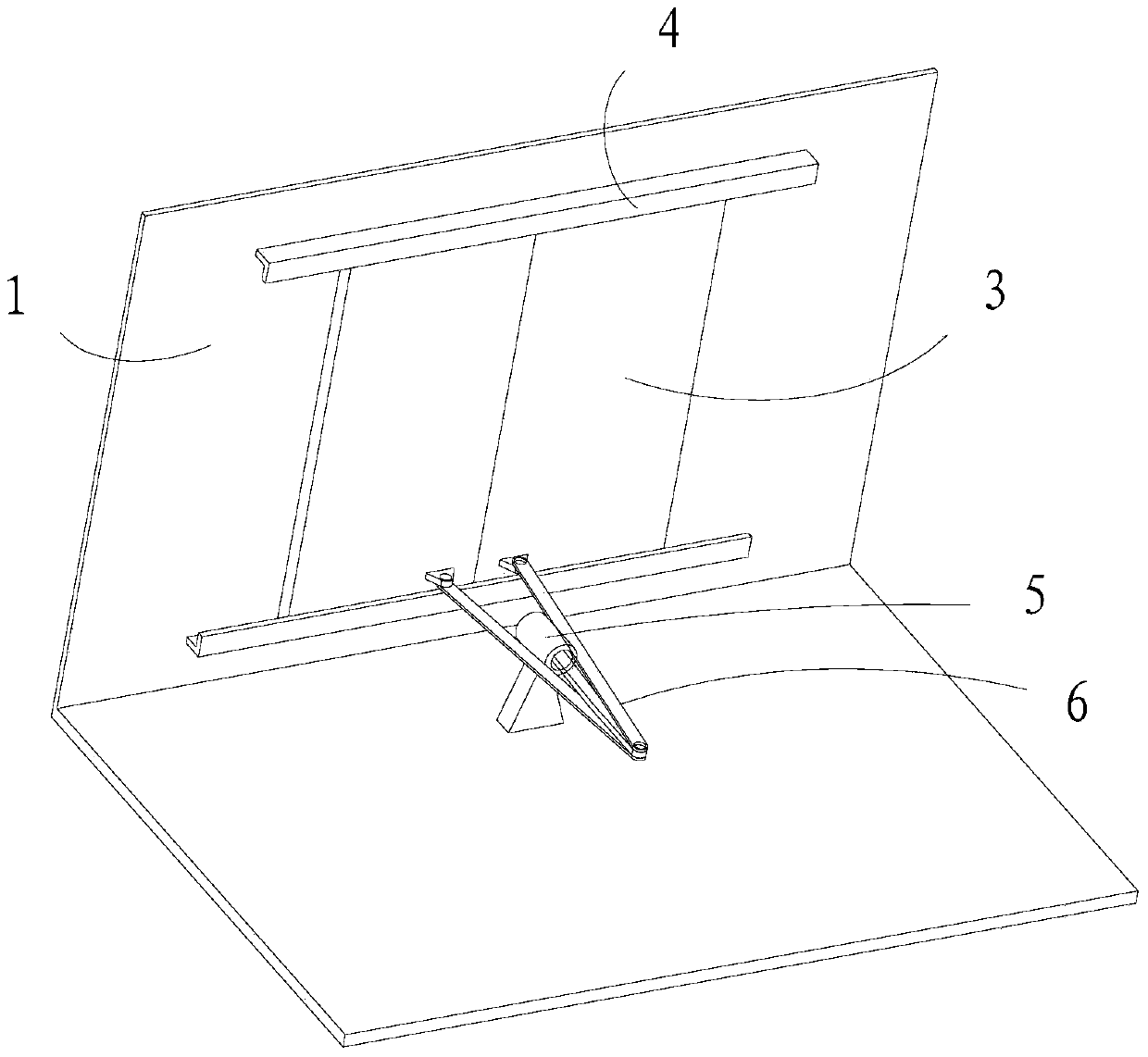

Embodiment 1

[0029] The invention relates to an HC adsorption device, which is cooperatingly arranged on the air intake pipe of the vehicle air intake system, and includes a blocking part cooperating with the air intake pipe, and is fixedly arranged relative to the vehicle and forms a drive with the blocking part. Connected drive mechanism. The blocking portion has a blocking surface not smaller than the cross-sectional area of the intake pipe, and when the engine is working, the blocking portion can fully open the intake pipe due to the drive of the driving mechanism, so that the intake pipe is free from intake air. The open state that blocks entry. When the engine stops working, the blocking part can block the intake pipe through the blocking surface due to the drive of the drive mechanism, so that the intake pipe is in a closed state.

[0030] The HC adsorption device can fully open the air intake pipe when the engine is working through the setting of the blocking part and the drivin...

Embodiment 2

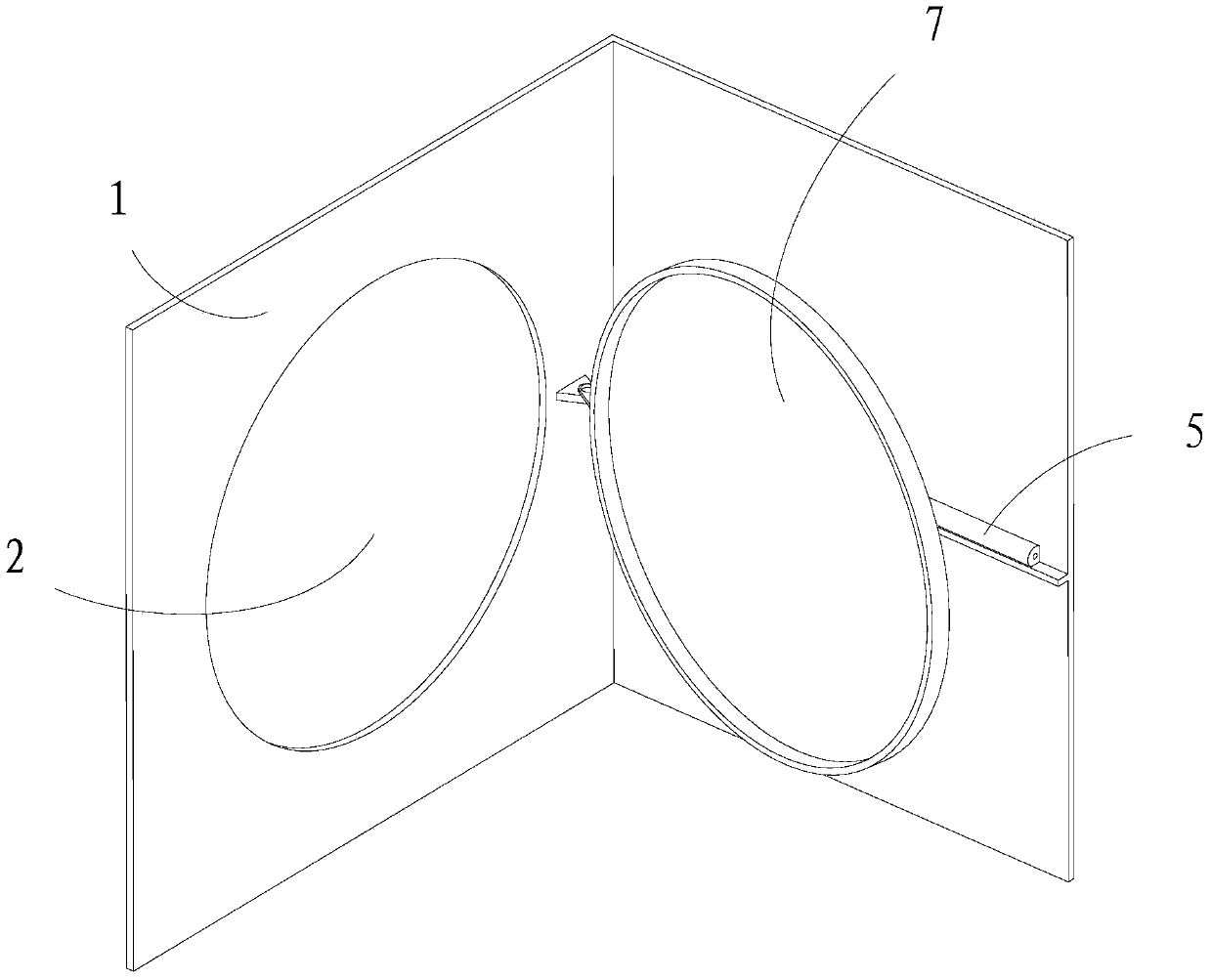

[0038] This embodiment relates to an HC adsorption device, which has roughly the same structure as the HC adsorption device in Embodiment 1, except that image 3 and Figure 4 As shown in , the blocking part in this embodiment is an overturned sealing unit 7 pivotally connected to the intake pipe 1 , and the overturned sealing unit 7 is formed with a blocking surface unit for sealing the intake section 2 . The drive mechanism of this embodiment still includes the electromagnetic valve 5 arranged on the vehicle, and the connecting rod 6 hinged between the electromagnetic valve 5 and the overturning blocking unit 7, which can drive the overturning blocking unit 7 under the action of the electromagnetic valve 5 Turn over relative to the intake pipe 1 to block the intake section 2 or open the intake section 2.

[0039] In this embodiment, besides the electromagnetic valve 5 , other power devices such as cylinders or linear motors can of course also be used, and the plugging surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com