Double-stroke crank round slider internal combustion engine cylinder jacket, engine body and internal combustion engine thereof

A crank round slider, two-stroke technology, applied in the machine/engine, cylinder, cylinder head and other directions, can solve the problems of bulkiness, bulky internal combustion engine and compressor, poor balance performance, etc., to reduce stiffness and strength requirements, improve Strength and stiffness, to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

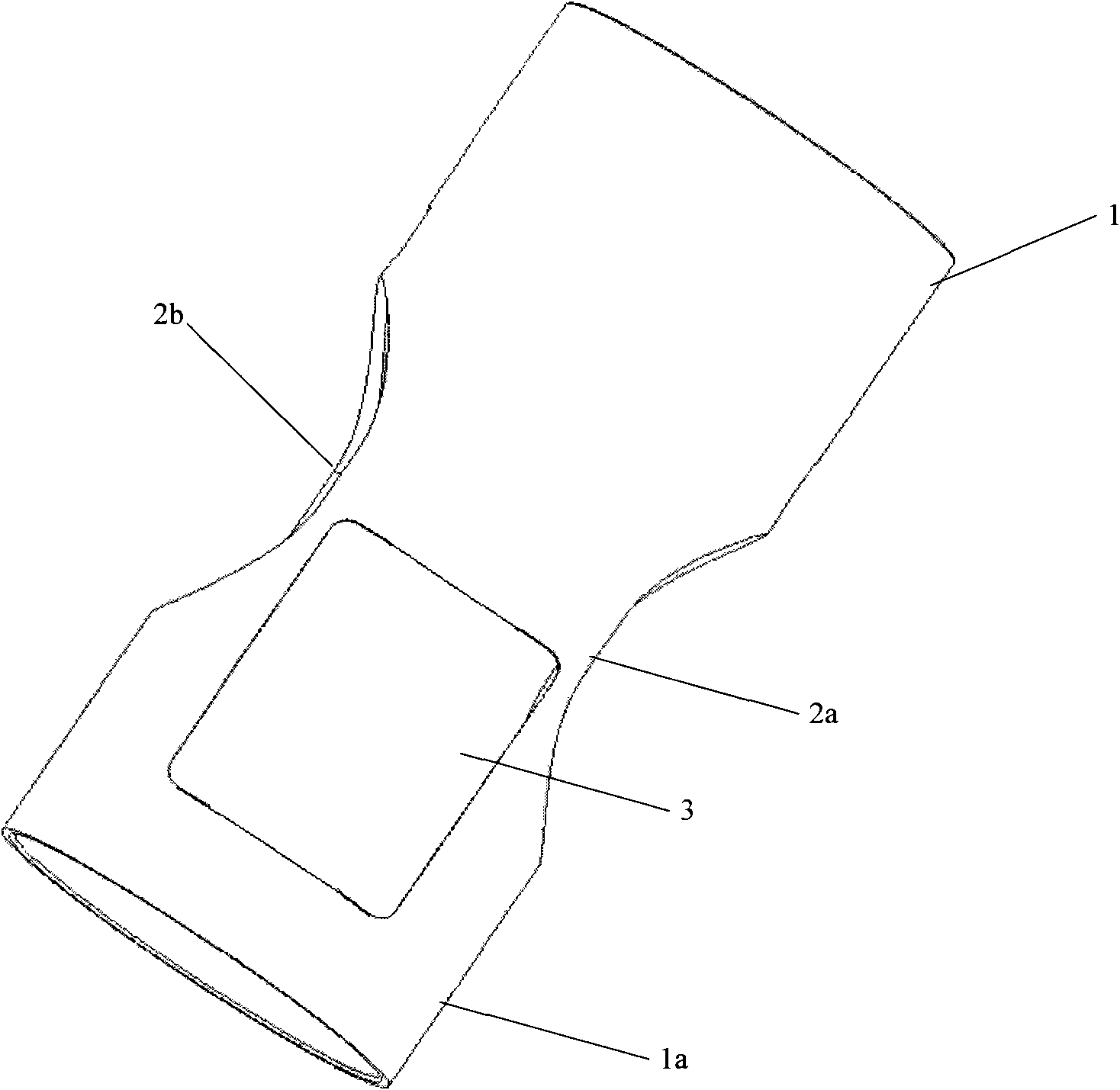

[0028] figure 1 It is the axonometric view of the first embodiment of the cylinder liner of the two-stroke crank and slider internal combustion engine of the present invention.

[0029] Such as figure 1 As shown, the cylinder liner of the two-stroke crank-slider internal combustion engine of the embodiment of the present invention includes a guide side wall 1 for accommodating the piston of the crank-slider internal combustion engine and capable of moving with the piston. In this embodiment, the guide side wall 1 is a cylindrical thin-walled part, its outer peripheral surface can cooperate with the body of the internal combustion engine, and its inner peripheral surface can cooperate with the piston head and the guide part, so that the piston can move along its central axis. reciprocating motion.

[0030] The cylinder liner can also have other shapes, but no matter what the shape of the cylinder liner is, its outline needs to match the body of the internal combustion engine,...

Embodiment 2

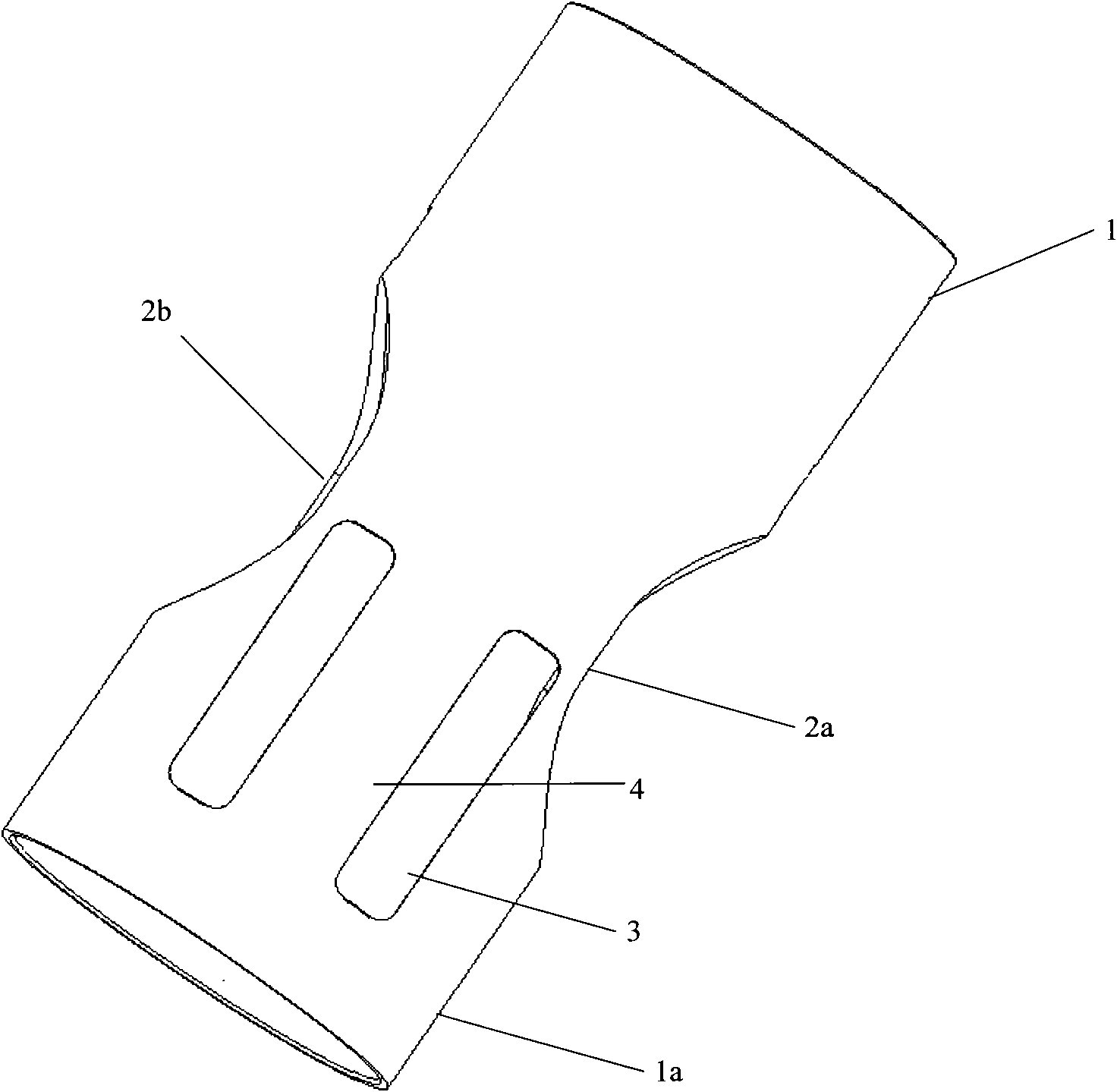

[0039] In the above-mentioned first embodiment, the cylinder liner intake inlet 3 is provided on the cylinder liner. Although the requirement for intake air into the crankshaft accommodation space can be met, the cylinder liner intake intake 3 will inevitably Affects the guiding action of the piston. In this embodiment, a guide plate is provided at the intake inlet of the cylinder liner. Please refer to figure 2 .

[0040] figure 2 It is the axonometric view of the second embodiment of the cylinder liner of the two-stroke crank and slider internal combustion engine of the present invention.

[0041] Such as figure 2 As shown, the difference from the first embodiment above is that in the cylinder liner 1 of this embodiment, a guide plate 4 is also provided at the inlet 3 of the cylinder liner, wherein the guide plate 4 is along the Set the direction of piston reciprocating motion.

[0042] In this embodiment, the air inlet 3 of the cylinder liner is square, and the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com