Air-blowing type micro gas turbine and starting method thereof

A micro gas turbine and air-blown technology, which is applied in the direction of gas turbine devices, combustion air/combustion-air treatment, machines/engines, etc., can solve the problems of high processing difficulty, reduced service life, high quality, etc., and achieve easy coaxiality Guaranteed, low processing difficulty, large air flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

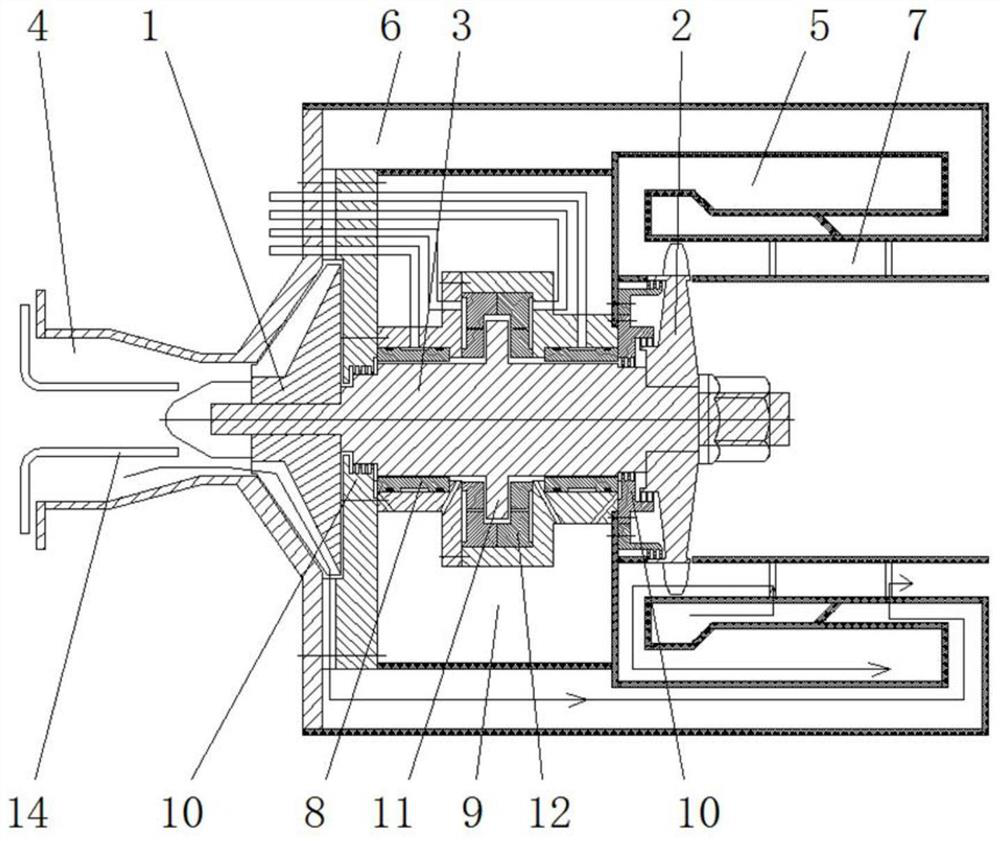

[0031] like figure 1 As shown, an air-blown micro gas turbine includes a compressor 1, a turbine 2, a rotating shaft 3, an intake passage 4, and a combustion chamber 5; the compressor 1 and the turbine 2 are respectively sleeved on the front end and the end of the rotating shaft 3 The front end of the compressor 1 is surrounded by a shell that surrounds the air intake passage 4, the outlet of the compressor 1 is connected to the combustion chamber 5 through the outlet passage 6, and the rim of the turbine 2 is arranged in the exhaust passage 7 of the combustion chamber 5, and the combustion chamber 5. The high-temperature and high-pressure gas ejected from the exhaust passage 7 is sprayed on the end face of the turbine 2 to drive the turbine 2 to rotate and do work; the rotating shaft 3 is supported in the stator by the radial bearing 8; each bearing is arranged on the rotating shaft between the compressor 1 and the turbine 2 On the shaft section, a bearing chamber 9 is formed...

Embodiment 2

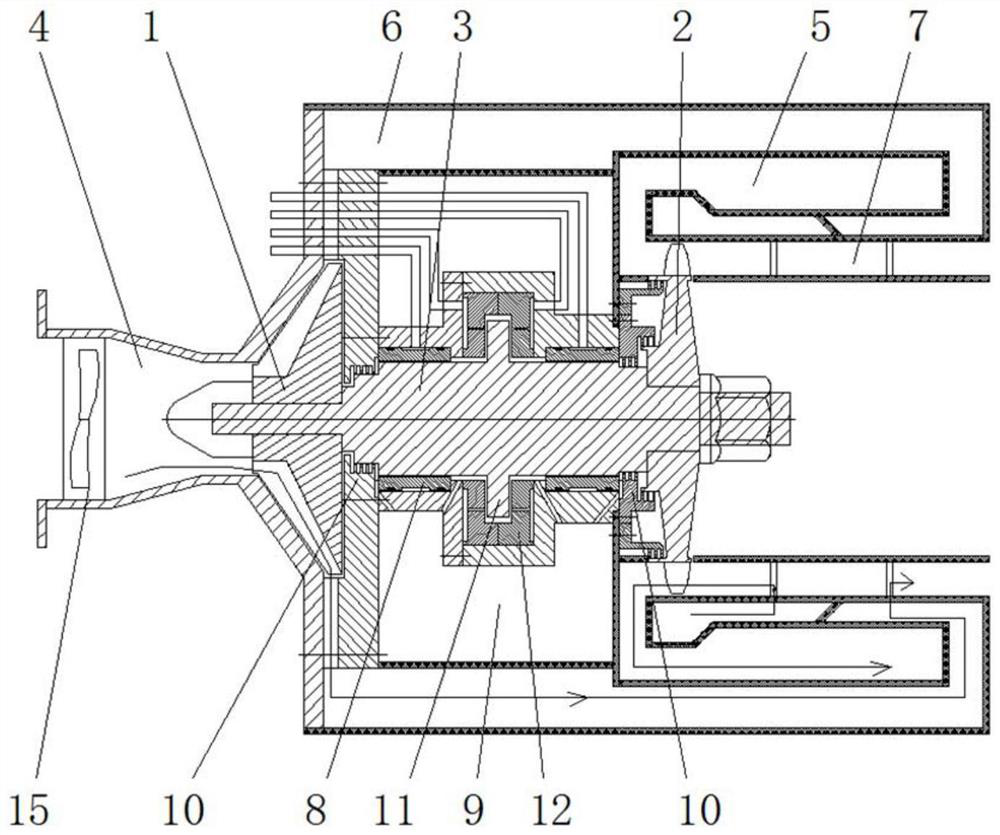

[0042] like figure 2 As shown, an air-blown micro gas turbine includes a compressor 1, a turbine 2, a rotating shaft 3, an intake passage 4, and a combustion chamber 5; the compressor 1 and the turbine 2 are respectively sleeved on the front end and the end of the rotating shaft 3 The front end of the compressor 1 is surrounded by a shell that surrounds the air intake passage 4, the outlet of the compressor 1 is connected to the combustion chamber 5 through the outlet passage 6, and the rim of the turbine 2 is arranged in the exhaust passage 7 of the combustion chamber 5, and the combustion chamber 5. The high-temperature and high-pressure gas ejected from the exhaust passage 7 is sprayed on the end face of the turbine 2 to drive the turbine 2 to rotate and do work; the rotating shaft 3 is supported in the stator by the radial bearing 8; each bearing is arranged on the rotating shaft between the compressor 1 and the turbine 2 On the shaft section, a bearing chamber 9 is forme...

Embodiment 3

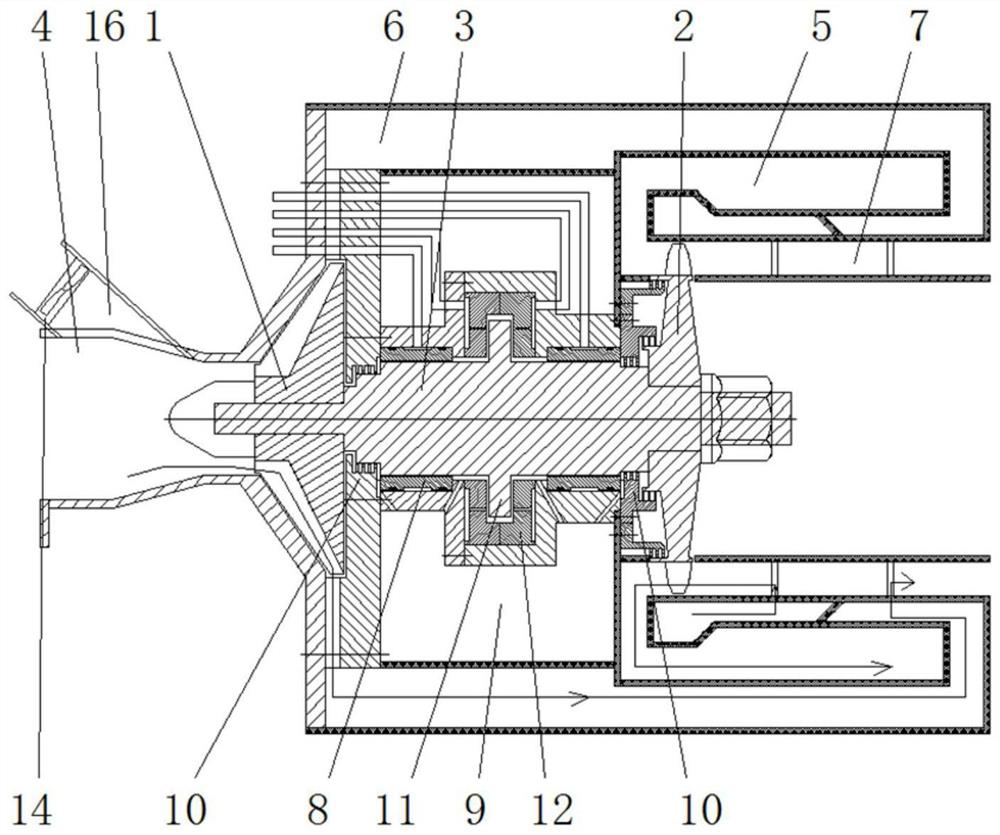

[0053] like image 3 As shown, an air-blown micro gas turbine includes a compressor 1, a turbine 2, a rotating shaft 3, an intake passage 4, and a combustion chamber 5; the compressor 1 and the turbine 2 are respectively sleeved on the front end and the end of the rotating shaft 3 The front end of the compressor 1 is surrounded by a shell that surrounds the air intake passage 4, the outlet of the compressor 1 is connected to the combustion chamber 5 through the outlet passage 6, and the rim of the turbine 2 is arranged in the exhaust passage 7 of the combustion chamber 5, and the combustion chamber 5. The high-temperature and high-pressure gas ejected from the exhaust passage 7 is sprayed on the end face of the turbine 2 to drive the turbine 2 to rotate and do work; the rotating shaft 3 is supported in the stator by the radial bearing 8; each bearing is arranged on the rotating shaft between the compressor 1 and the turbine 2 On the shaft section, a bearing chamber 9 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com