Breather valve applied to breathing machine and control method of breather valve

A breathing valve and ventilator technology, which is applied in the field of medical equipment, can solve the problems of unfavorable gas breathing valve, poor exhaust of breathing valve, and difficulty breathing of patients, so as to achieve the effect of increasing pressure, smooth exhaust and reducing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

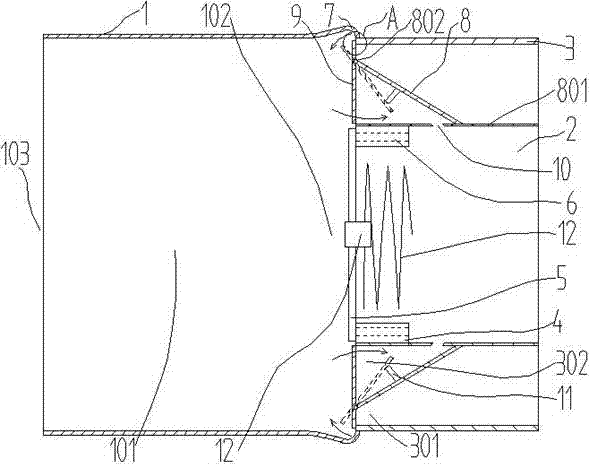

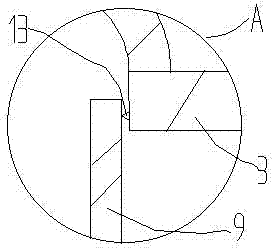

[0030] Such as Figure 1 to Figure 5 The shown breathing valve used on the ventilator includes: a valve body 1 with a rectangular cross section, with a cavity 101 in the valve body 1;

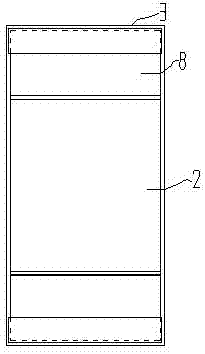

[0031] The intake pipe 2 and the outer pipe 3, the intake pipe 2 and the outer pipe 3 are all arranged on the intake and exhaust end 102 of the valve body 1, the intake and exhaust end 102 is arranged opposite to the breathing end 103, the cross section of the intake pipe 2 is rectangular, and the outer pipe 3 In order to form a rectangular tube on the two opposite surfaces of the intake pipe 2, the inner wall of the exhaust end of the intake pipe 2 is fixedly installed with a seat ring 4, and the end of the seat ring 4 is equipped with a valve that can be opened and closed and restricts the flow of gas from the cavity 101 to the air outlet. The diaphragm 5 flowing in the intake pipe 2 can be made of silicon rubber, and the middle part of the diaphragm 5 is fixedly installed on a pillar, and th...

Embodiment 2

[0038] On the basis of Embodiment 1, add the following technical features: as Figure 1~6 As shown, a solenoid valve 14 is provided in the communication hole 10, and the middle part of the valve body 1 is provided with a temperature sensor a and an air flow detector b respectively. Connection, the processor, the solenoid valve 14, the temperature sensor and the airflow direction detector are respectively adapted to be equipped with power supplies.

[0039] The method for controlling the breathing valve used on the ventilator is characterized in that it comprises the following steps:

[0040] 1) There is oxygen in the intake pipe, the pressure in the valve body 1 is lower than the pressure in the intake pipe 2 when inhaling, the temperature sensor measures the temperature in the valve body, when the temperature is too low, the processor controls the spiral heating coil 12 to The set power works, when the temperature is at a normal value, the processor controls the spiral heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com