Oil paint coating construction method under high temperature and high humidity environment

A high-temperature, high-humidity, construction method technology, applied in the device, coating, surface pretreatment, etc. for coating liquid on the surface, to achieve the effect of fine coating, shortening the construction period, and selecting scientific and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069]The paint coating construction method under the high temperature and high humidity environment of the present invention is applied to the construction of 36 steel bins in the main batching room of the Formosa Plastics sintering project in Vietnam, and is also used in the fuel storage tank room, coarse crushing room, fine crushing room, etc. of the sintering project. The construction of a total of 15 steel silos in the quicklime and dust batching room and the steel silos of the Formosa Plastics Steel Slag Project in Vietnam, the specific construction steps are as follows:

[0070] a. Selection of paint system

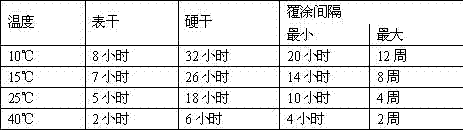

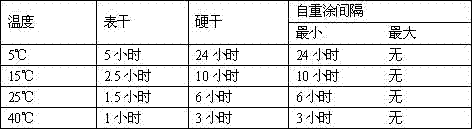

[0071] The paint system of this project is shown in the table below:

[0072]

[0073] Note: This system is suitable for: 1. New construction, welding bead and paint repair project. 2. Surface roughness requirement: 50-70μm.

[0074] b. Paint surface treatment

[0075] Degreasing and degreasing

[0076] Use water-based biodegradable cleaners to remove oil, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap