Distributing Apparatus And Method For Supplying Particulate Material Continuously To A Forming Belt

A molding belt and guiding device technology, which is applied in the pretreatment, application, household appliances and other directions of molding materials, can solve the problems of reducing stability, density unevenness, density difference, etc., and achieves a simple structure and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

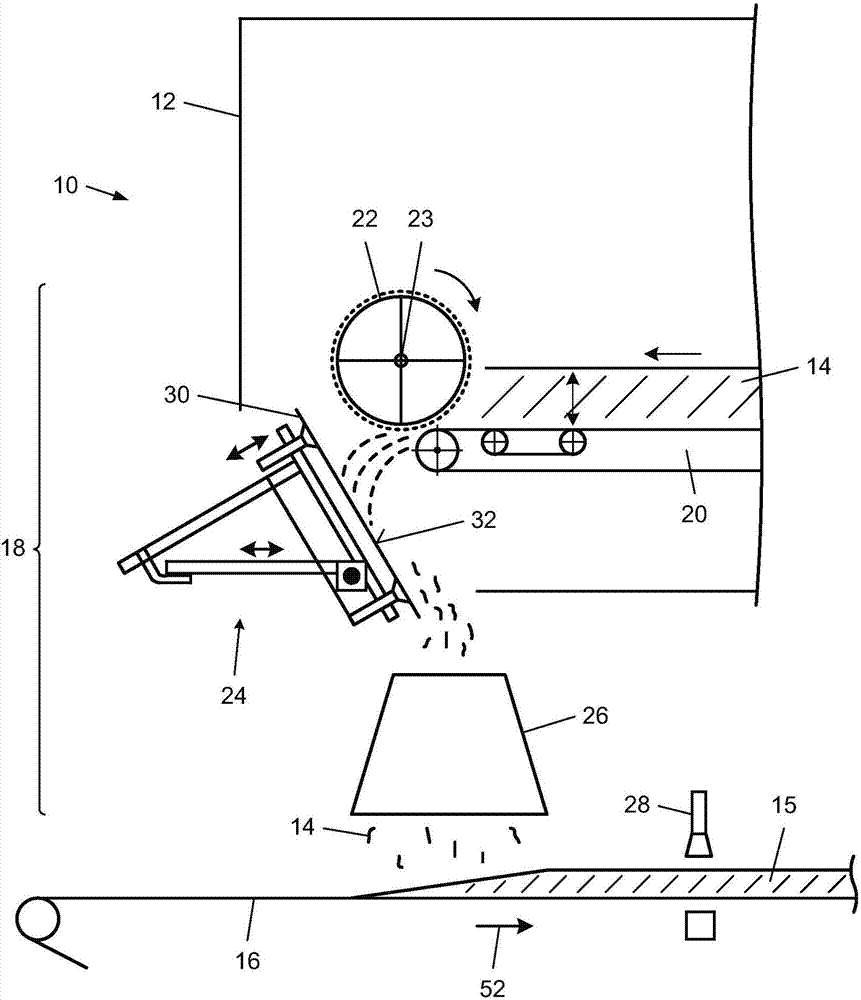

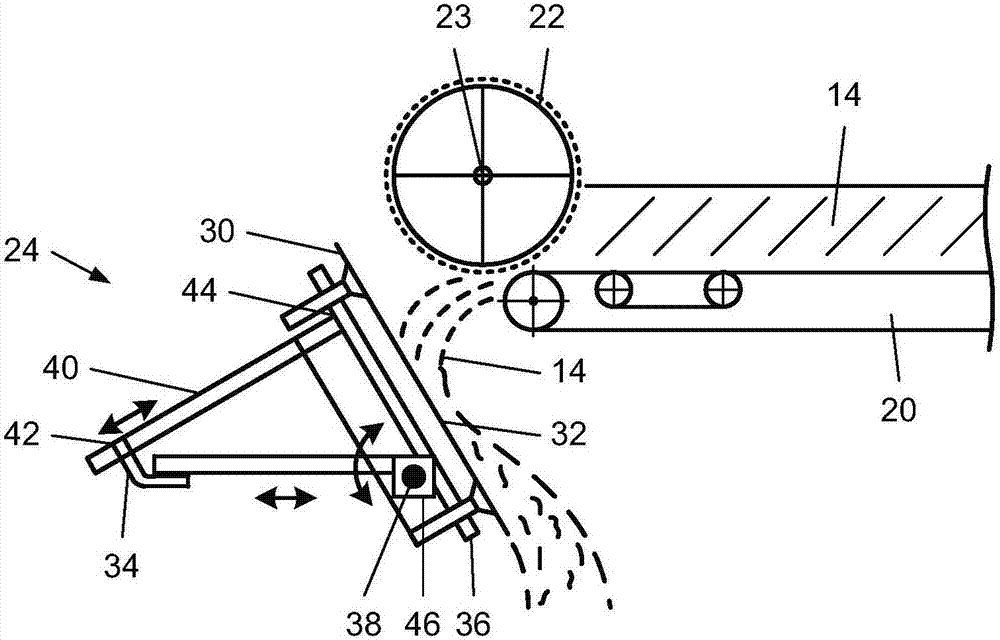

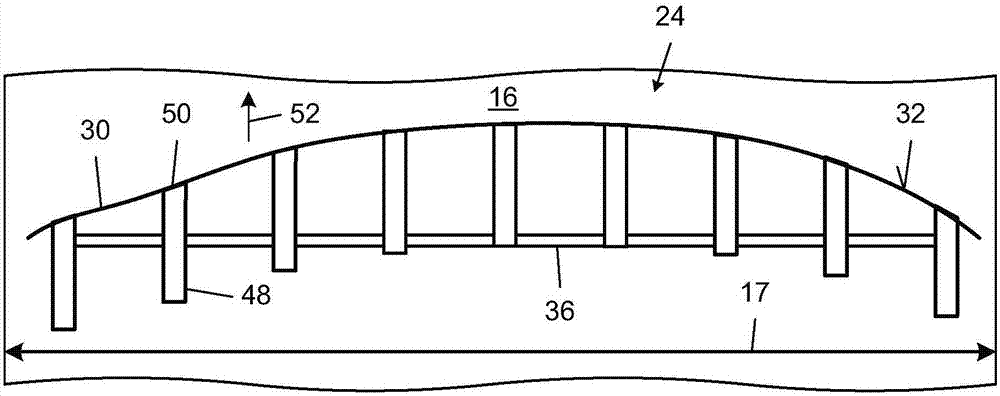

[0051] exist figure 1 A structure 10 according to the invention for the continuous production of material sheets is shown in a schematic sectional view. The structure includes a spread store 12 to store a stock of spread 14 . The structure 10 further includes a forming belt 16 through which the spread 14 is fed into a continuous or discontinuous press (not shown) for pressing. Additionally, the structure 10 includes an optional spreading device 18 to continuously apply the spreading material 14 to the forming belt 16 . Direct spreading on the forming belt 16 is also possible with the spreading material store 12 , wherein indirect spreading is preferably carried out using a spreading head adapted to the spreading material 14 .

[0052] Such structures can be used in plants for producing panels of material. In such an apparatus, a spread reservoir 12 is used to buffer the glued material, referred to herein as a spread 14 . The spread storage 12 may also be referred to as a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com