Photo-curing three-dimensional printing device based on UV LED micro-display technology and printing method of photo-curing three-dimensional printing device

A 3D printing and micro-display technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of slow printing speed, large equipment, low precision, etc., to improve production efficiency, reduce parts, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

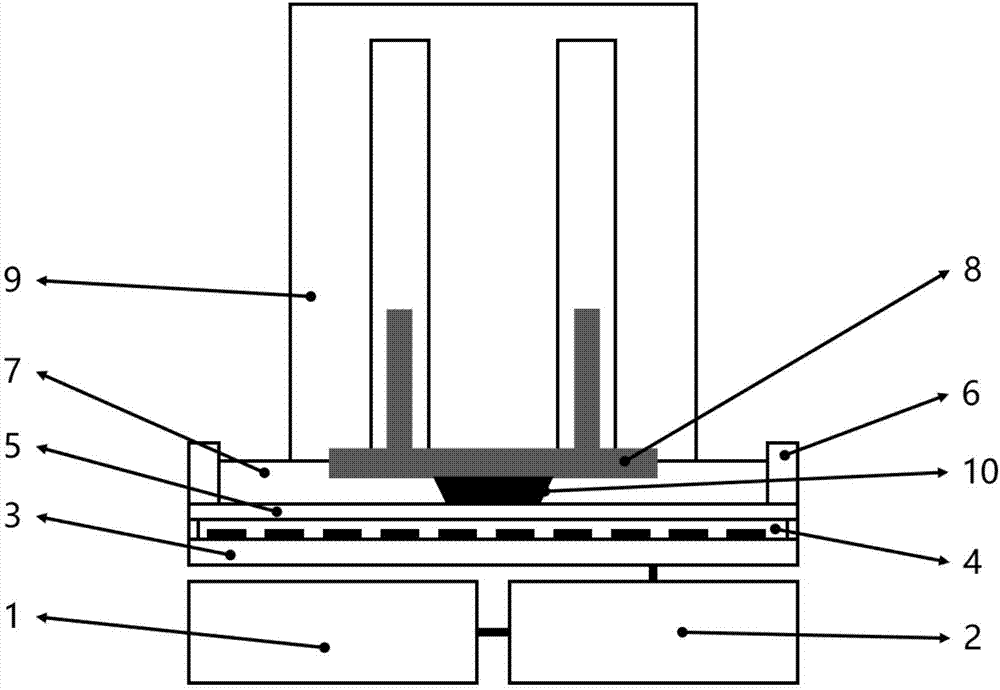

[0029] Example 1 - Ascending UV Micro LED Flat Panel Display Photocuring 3D Printing Device

[0030] refer to figure 1 The three-dimensional printing device based on the ultraviolet LED micro-display technology provided in this embodiment includes: a computer system 1, a controller 2, an ultraviolet LED micro-display device, a material tank 6, a forming table 8 and a lifting device 9;

[0031] Wherein, the computer system 1 performs image processing on the three-dimensional model, and divides the three-dimensional model into a series of cross-sectional graphics with thickness. Then, the processed data is sequentially transmitted to the controller 2, the display driving circuit 3, and the miniature ultraviolet LED chip array 4 through the data line.

[0032] In the embodiment, the display driving circuit 3, the micro-ultraviolet LED chip array 4, and the cover plate 5 are mainly used as an ultraviolet Micro LED flat-panel display device to realize the display of ultraviolet pa...

Embodiment 2

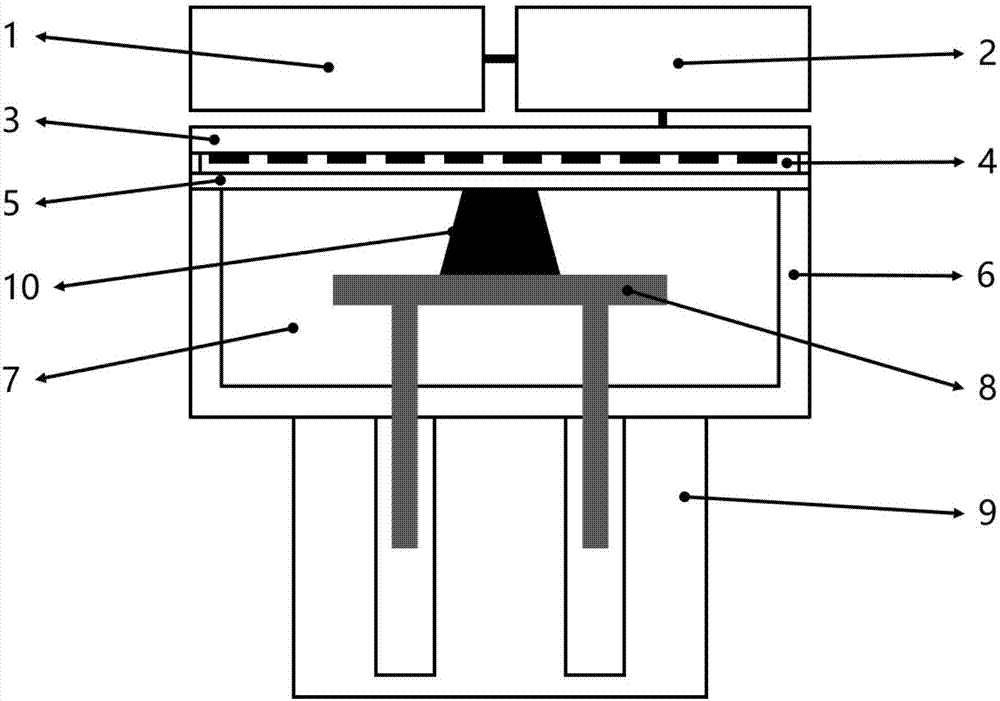

[0038] Example 2—Sunken UV Micro LED Flat Panel Display Photocuring 3D Printing Device

[0039] refer to figure 2 , different from Embodiment 1, in this embodiment, the ultraviolet Micro LED display assembly is located above the entire device, and the trough 6 and molding table 8 are located below the entire device. Forming table 8 utilizes lifting device 9 to be able to do vertical movement in the trough. Between the bottom surface of the cover plate 5 and the forming table 8 is the forming working area of the three-dimensional printer.

[0040] Before printing starts, the photocurable resin 7 is filled in the material tank 6 . Forming platform 8 descends to the position apart from cover plate 5 bottom surface unit height.

[0041] When printing starts, the controller 2 controls the display drive circuit 3 to selectively drive and light up the ultraviolet LED chip array 4, and the emitted ultraviolet light image passes through the cover plate 5 and reaches the space abo...

Embodiment 3

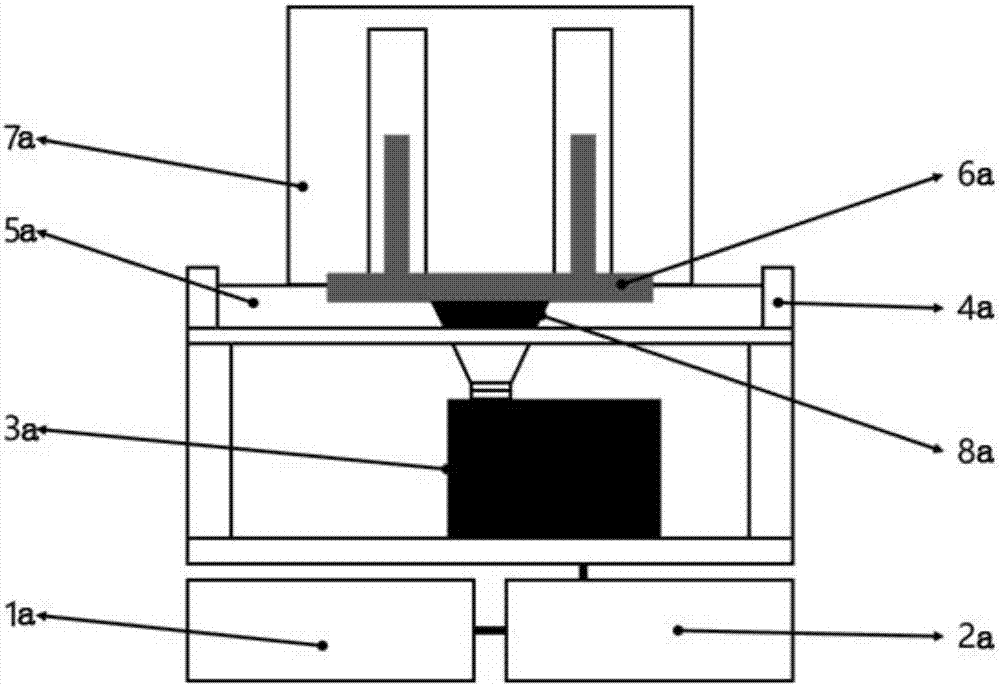

[0043] Example 3 - Ascending UV Micro LED projection display photocuring three-dimensional printing device

[0044] refer to image 3 , different from Embodiment 1, in this embodiment, an ultraviolet Micro LED projection display device is used as an ultraviolet Micro LED projection display device to realize the display of ultraviolet images. The ultraviolet Micro LED projection display device is mainly composed of a display driving circuit, a micro LED array chip and an optical lens group. The ultraviolet image group obtained by the computer system 1a enters the display drive circuit in the ultraviolet Micro LED projection display device 3a after being processed by the controller 2a, and the highly integrated micro LED chips on the micro LED array chip are selectively driven When it is turned on, the ultraviolet light image emitted by the chip is modulated by the optical lens group and finally converges on the molding working surface in the photocuring resin 5a of the materia...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap