Metal filament blended yarn weaved fabric and treating technology thereof

A technology of blended fabrics and processing technology, applied in the field of textile fabrics, can solve the problems of cumbersome processing technology, single function, and large pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail now in conjunction with embodiment.

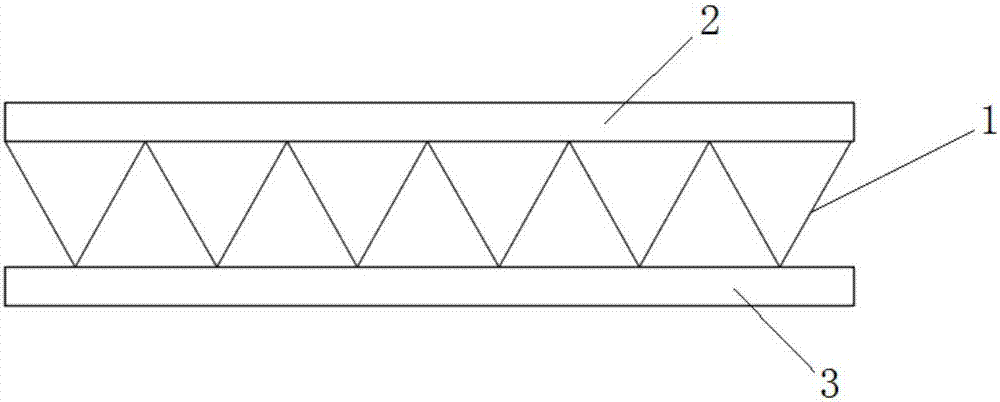

[0031] Such as figure 1 As shown, a metal wire blended fabric comprises a base cloth 1, a face cloth 2 and a base cloth 3, the base cloth 1 is a flannelette with a V-shaped structure, the face cloth 2 is pure cotton, and the base cloth 3 includes The ground warp and the weft yarn, the ground warp and the weft yarn are parallel wires of metal wire and cotton yarn.

[0032] The ground warp and weft yarns are paralleled by twisting method using 60S / 2 cotton yarn and 68D metal wire, the thickness is 4mm, and the weft yarn density and ground warp density are 400 / 10 cm.

[0033] The above-mentioned metal wire blended fabric can not only achieve the effect of radiation protection, but also the fluff on the cloth surface can also play a considerable thermal effect, which is especially suitable for office workers in winter.

[0034] A treatment process for the above-mentioned metal wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com