A device for removing zinc pot bottom slag

A technology of zinc pot and zinc liquid, which is applied in the direction of coating, metal material coating process, hot-dip galvanizing process, etc., can solve the problems of poor operability, complex structure, and low efficiency of slag removal, and achieve a simple structure and easy replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The device for removing zinc pot bottom slag according to the present invention will be further explained below in conjunction with the accompanying drawings and specific examples, but the explanation does not constitute an improper limitation to the technical solution of the present invention.

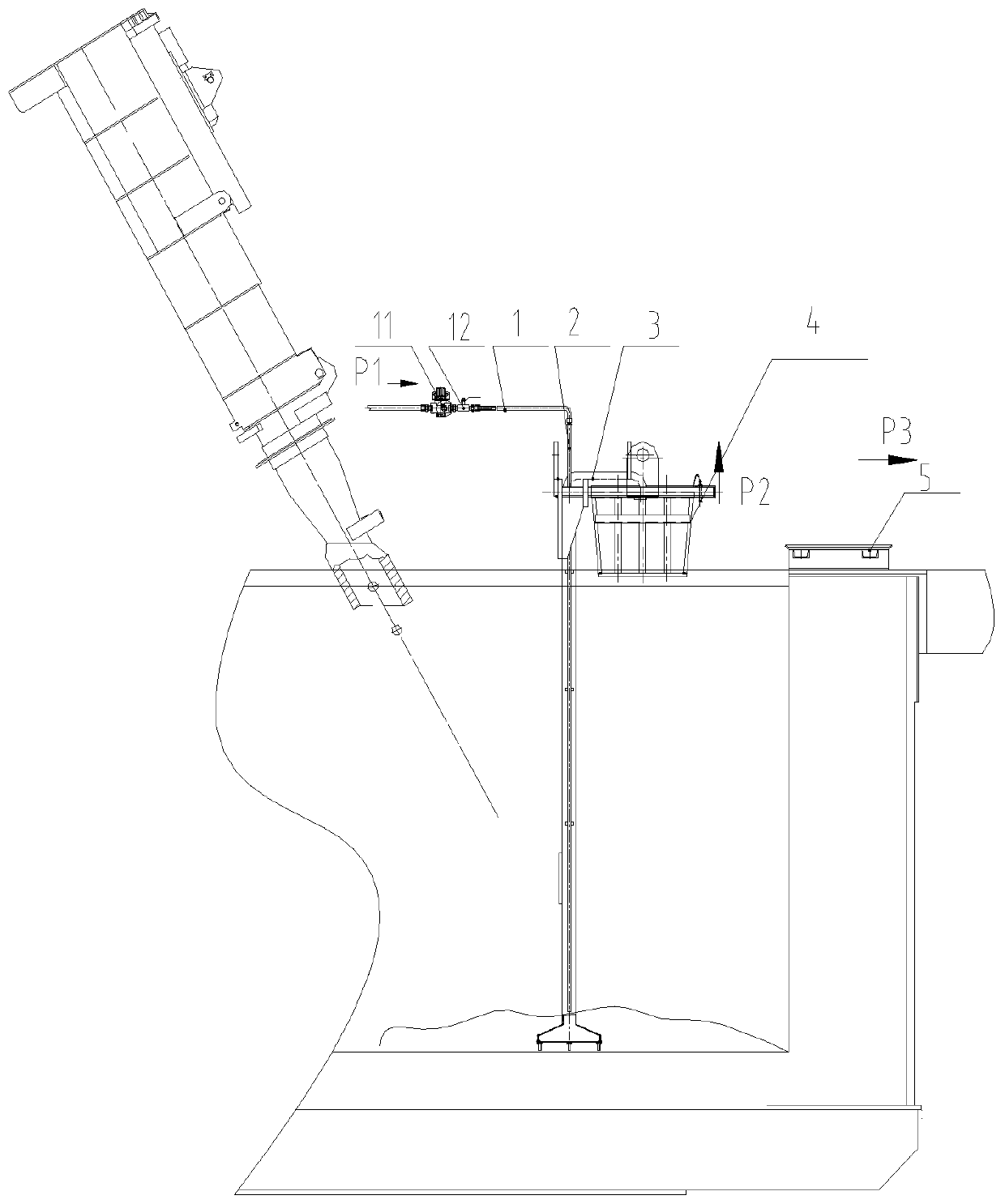

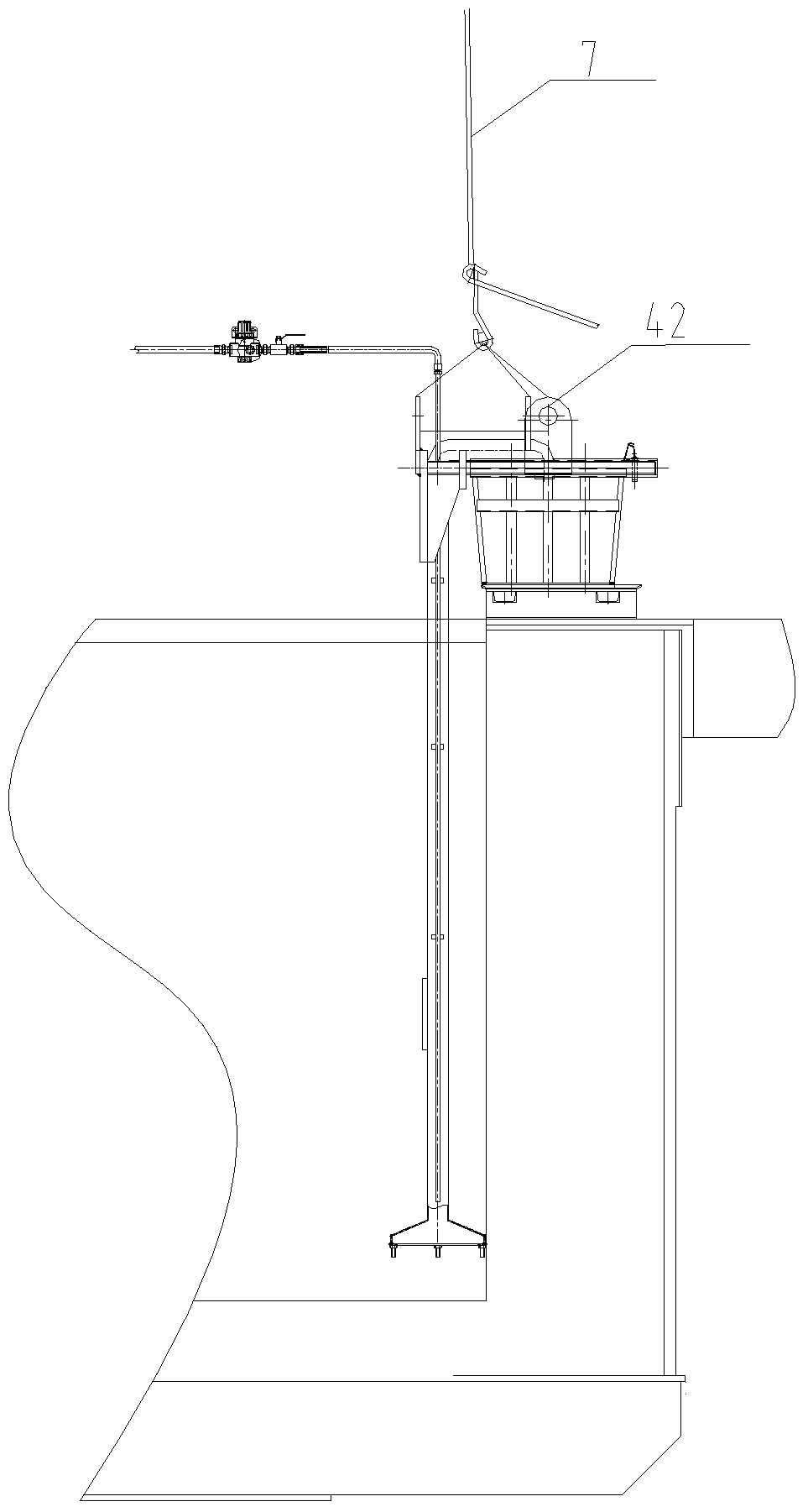

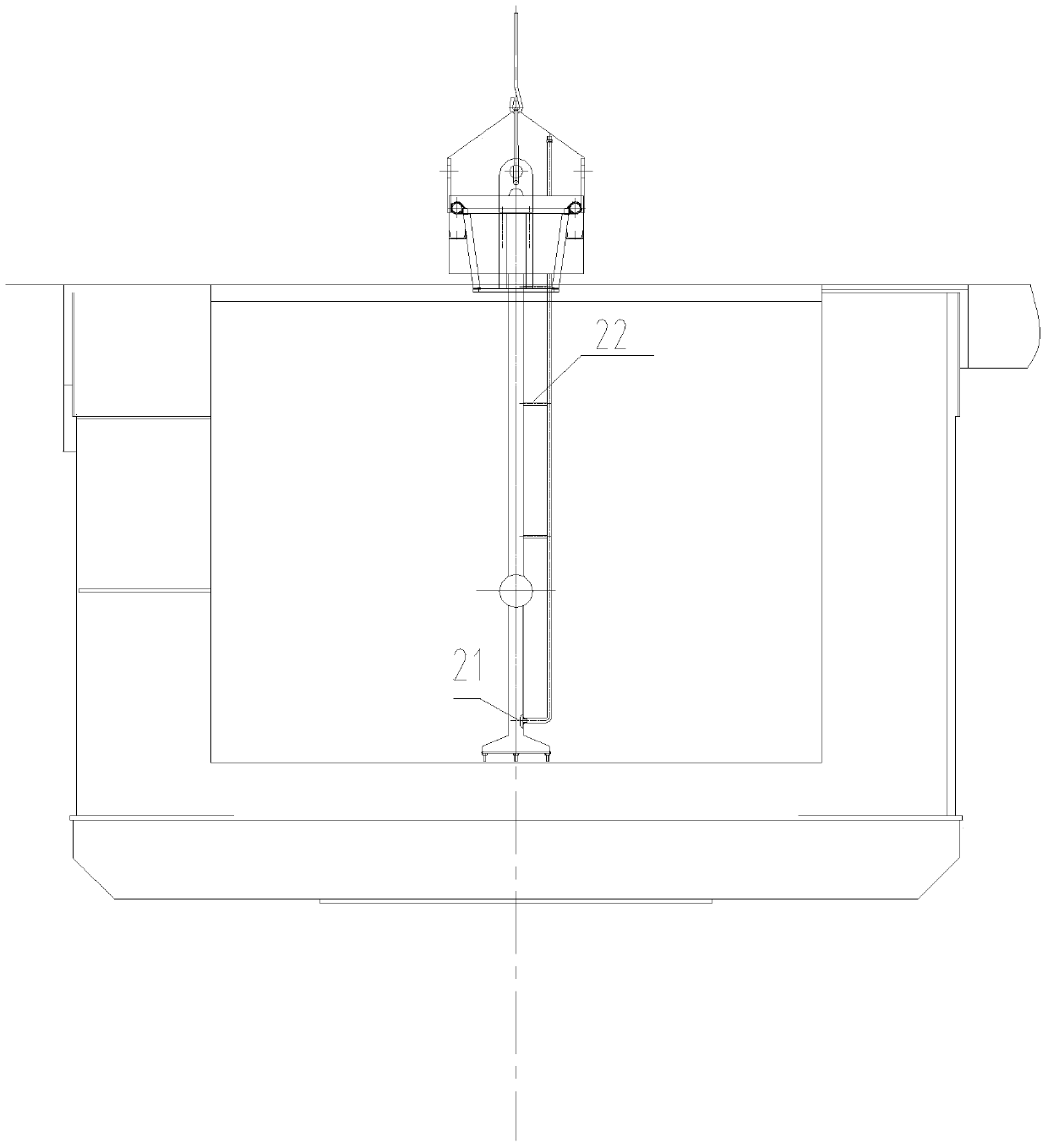

[0041] figure 1 It shows the structure of the device for removing zinc pot bottom dross in one embodiment of the present invention. Such as figure 1As shown, the edge of the zinc pot is provided with a pot edge backing plate 5, and the device for removing the slag at the bottom of the zinc pot is located in the zinc pot. The device for removing the bottom of the zinc pot includes a nitrogen gas introduction pipe 2, a suction main pipe 3 and a filter basket 4. The nitrogen pipe 1 and the nitrogen inlet pipe 2 are connected at the 90-degree elbow of the nitrogen pipe 1, wherein the nitrogen pipe 1 is provided with a pressure reducing valve 11 and a manual stop valve 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com