Stepless height adjusting spherical support

A spherical bearing and height adjustment technology, which is applied in bridge materials, buildings, bridge construction, etc., can solve the problems of affecting the smoothness of the line, long height adjustment operation period, and high construction cost, so as to improve operation efficiency, short cycle, Turn up the effect of high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

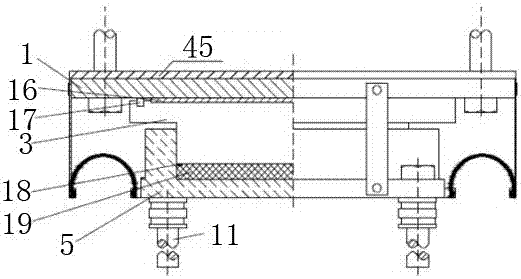

Embodiment 1

[0051] When using this patent for manual height adjustment, when the bridge deck height monitoring system 15 detects that the deviation between the bridge deck height and the reference height reaches the set threshold value, the vertical height adjustment of the support needs to be set through the calculation of the detection data of the bridge deck height monitoring system 15 start the vertical pushing device 10, lift the lower seat plate 5 to the preset height by the jack, and complete the adjustment of the vertical height of the upper structure of the support. The end structure B602 double helix structure is separated, and the vertical load of the support is carried by the jack. After the vertical height adjustment is completed, manually start the horizontal worm gear transmission mechanism, the servo motor 10 drives the worm 8 to rotate, the worm 8 drives the worm wheel 7, and the worm wheel 7 rotates with the inner and outer double helix end surface structure B602 until th...

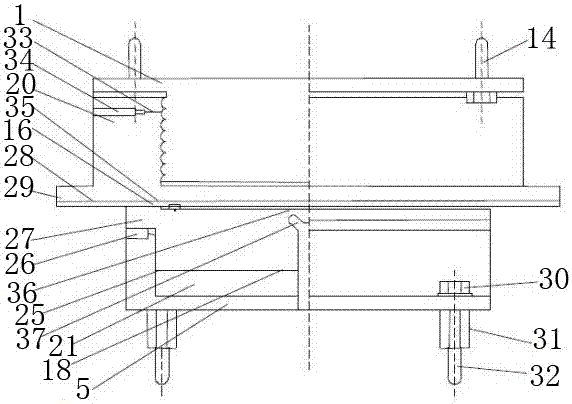

Embodiment 2

[0053] When using this patent for semi-automatic height adjustment, when the bridge deck height monitoring system 15 detects that the deviation between the bridge deck height and the reference height reaches the set threshold value, the vertical height adjustment of the support that needs to be set is calculated through the detection data of the bridge deck height monitoring system 15 manually load the power source and control system on the device, start the vertical pushing device 10 through the control system according to the calculated amount, lift the lower seat plate 5 to the preset height by the jack, and complete the vertical height adjustment of the upper structure of the support Adjustment, at this time the inner and outer double helix end surface structure A601 of the lower seat plate 5 is separated from the inner and outer double helix end surface structure B602 double helix structure, and the vertical load of the support is carried by the jack. After the vertical he...

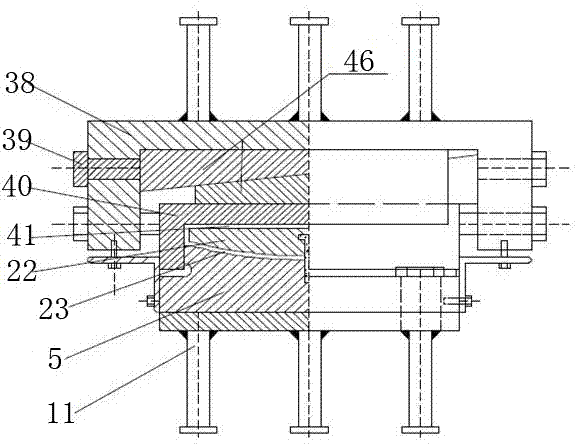

Embodiment 3

[0055] When using this patent for fully automatic height adjustment, when the bridge deck height monitoring system 15 detects that the deviation between the bridge deck height and the reference height reaches the set threshold value, the detection data of the bridge deck height monitoring system 15 is sent to the controller or the self-contained remotely. The control system calculates the vertical adjustment amount of the support to be set, and the control system starts the vertical pushing device 10 in real time according to the obtained data, and lifts the lower seat plate 5 to the preset height by the jack to complete the vertical adjustment of the upper structure of the support. For height adjustment, the inner and outer double helix end surface structure A601 of the lower seat plate 5 is separated from the inner and outer double helix end surface structure B602 double helix structure, and the vertical load of the support is carried by the jack. After the vertical height ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com