Method and device for performing leakage testing on fuel injection valve of internal combustion engine

A fuel injection valve and leakage detection technology, which is applied in the direction of fuel injection device, measurement device, engine test, etc., can solve the problems of unfavorable cost, assembly cost, etc., improve measurement resolution or signal/noise-ratio, and improve expression effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

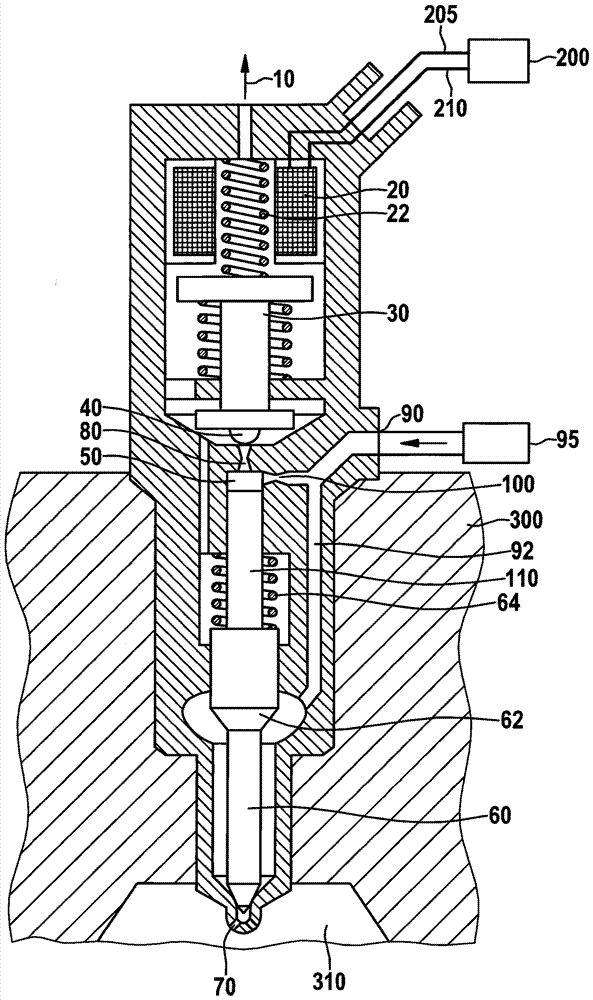

[0024] By means of the known from DE 10 2004 055 575 A1 and in figure 1 The electrically actuatable solenoid valve injector shown in FIG. 1 regulates the start of injection and the injection quantity of fuel into the combustion chambers of cylinders 300 of the internal combustion engine. Fuel enters the high-pressure-inlet channel from a high-pressure fuel source 95 , which includes, for example, in the case of a common rail system, at least one high-pressure fuel pump and a high-pressure accumulator (fuel rail) via a high-pressure connection 90 (Hochdruckanschluss) 92 to the injection nozzle 60 , also referred to as the nozzle needle, and through the inlet throttle valve 100 into the valve control space 50 . The valve control space 50 is connected to the fuel return 10 via a meter-out valve 80 which can be opened by a solenoid valve consisting of a magnetic coil 20 , an armature 30 (Magnetanker) and a valve ball 40 .

[0025] In the closed state of the meter-out valve 80 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com