High-pressure water pump

A pumping pump and high-pressure technology, applied in the field of pressurized water pumps, can solve the problems of ineffective utilization, large water potential difference, unenvironmental protection, etc., and achieve the effects of low cost, improved water energy utilization rate, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

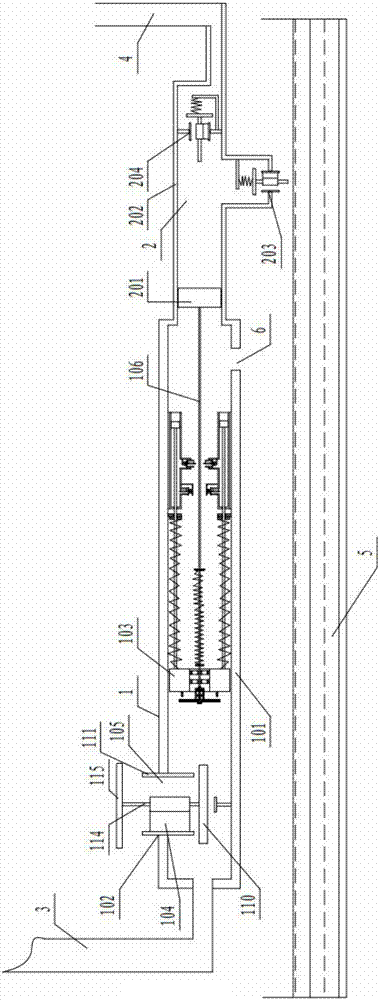

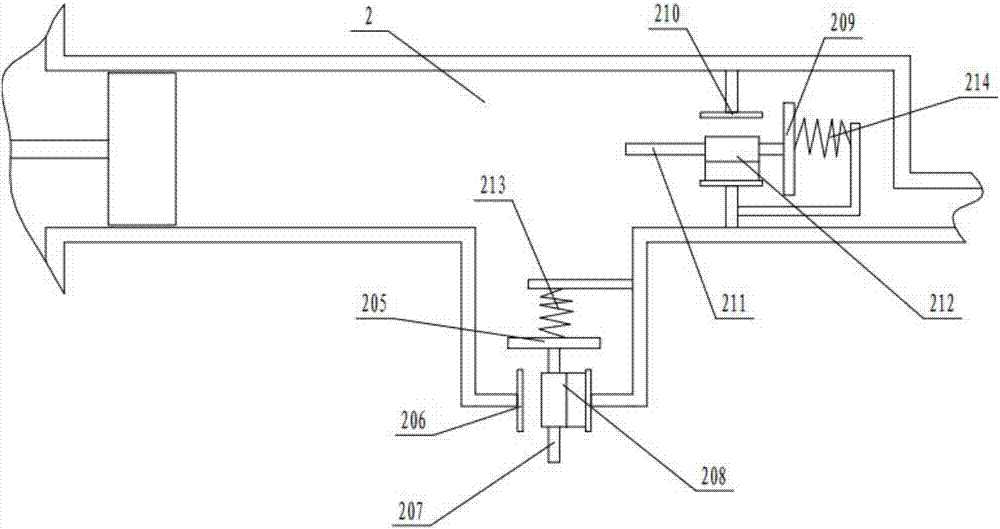

[0024] Embodiment 1: as Figure 1~Figure 6 As shown, a high-pressure water pump includes a pressurizing device 1 and a water pump 2. The water inlet pipe 3 of the pressurizing device 1 is connected to a high-level water source port and can drive the water pump 2 to operate. The water pump 2 is provided with a water inlet and an outlet. The water inlet, the water inlet of the water pump 2 is connected to the reservoir 5 or the water source outlet, the water in the reservoir is the water overflowed by the pressurizing device, and the water outlet is connected to the user water supply pipe 4.

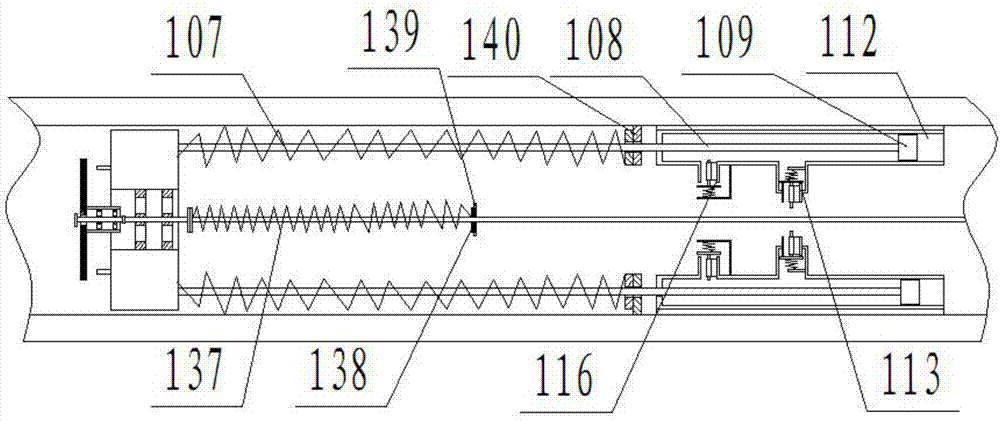

[0025] Preferably, the above-mentioned pressurizing device 1 includes a cavity 101, the side wall of the water inlet end of the cavity 101 is provided with a valve 102, and the water outlet end is provided with a piston pushing mechanism, the piston pushing mechanism includes a large piston 103 and a piston rod 106, and the large piston 103 is placed In the cavity 101 , one end of the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com