Air-cooled intermediate bearing

An intermediate bearing and air-cooling technology, which is applied in the direction of bearing cooling, bearing components, shafts and bearings, etc., can solve the problems of affecting the ship's hydropower resources, prone to eccentric wear, poor heat conduction effect, etc., achieve good heat dissipation effect, prolong service life, Ensure the effect of the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with drawings and embodiments.

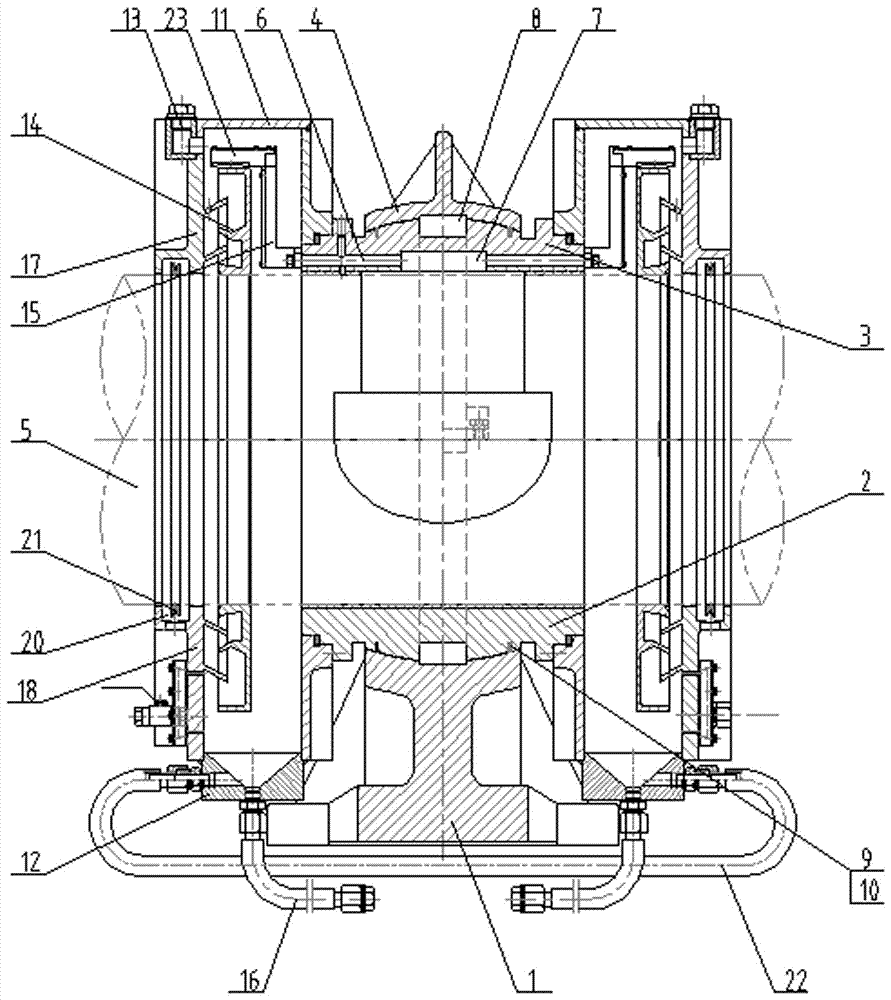

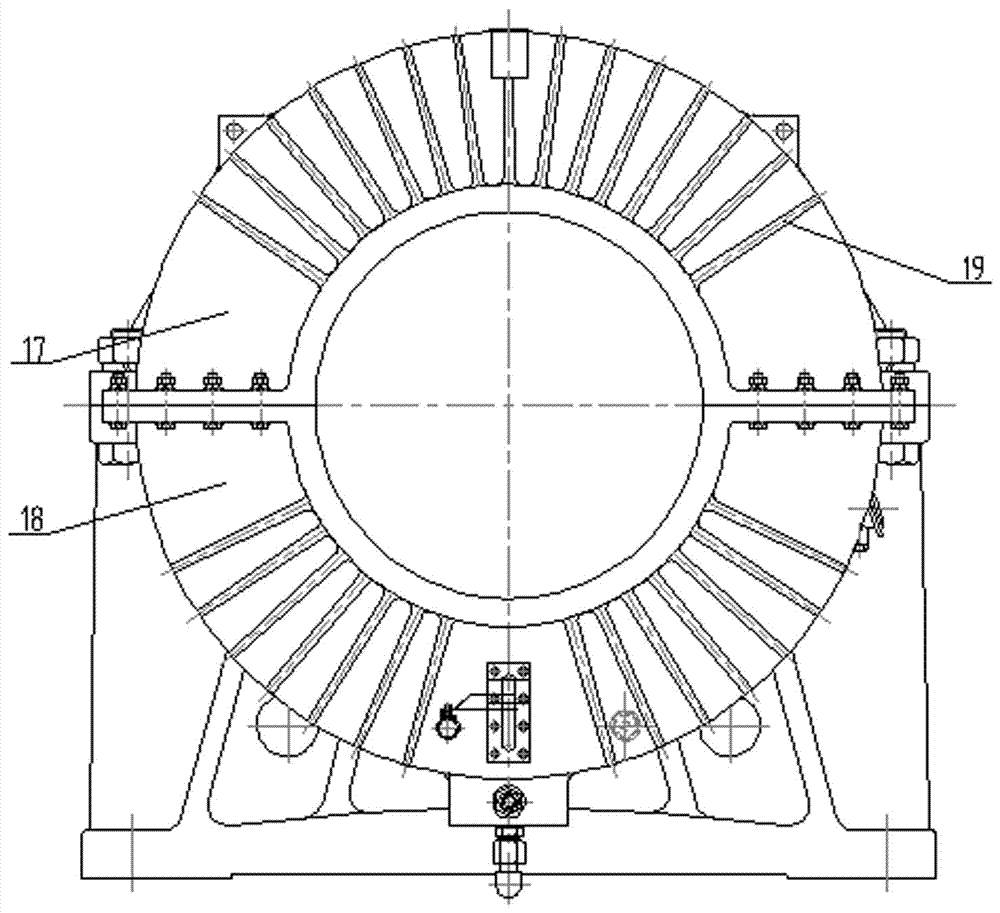

[0016] figure 1 , 2 As shown: an air-cooled intermediate bearing includes a bearing seat 1, upper and lower bearing bushes 3, 2 and a bearing cover 4, and the upper and lower bearing bushes 3, 2 hold the shaft 5 supported on the bearing seat 1 and covered by the bearing cover 4, On the supporting surface of the lower bearing bush 2 and the bearing seat 1, and on the cover mounting surface of the upper bearing bush 3 and the bearing cover 4, there are oil seal cavities 9 with oil seals 10 on both sides. The support contact surface is spherical. Both sides of the upper and lower bearing bushes 3, 2 are connected with outer oil tanks, and the outer oil tanks include upper and lower oil tank bodies 11, 12, upper and lower side covers 17, 18, oil throwing pan 14, oil collection box 23, and oil inlet pipeline 15. The upper and lower oil tanks 11, 12 are connected to the outer sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com