Integrated circuit and method for calibrating temperature drift of bandgap reference voltage using self-heating

A reference voltage and integrated circuit technology, which is applied in the field of integrated circuits that use self-heating to calibrate the temperature drift of the bandgap reference voltage, can solve the problems of large reference voltage temperature drift, long calibration time, poor consistency, etc., and achieve rapid local heating, Time-saving and cost-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions in this application, the technical solutions in this application will be clearly and completely described below in conjunction with embodiments.

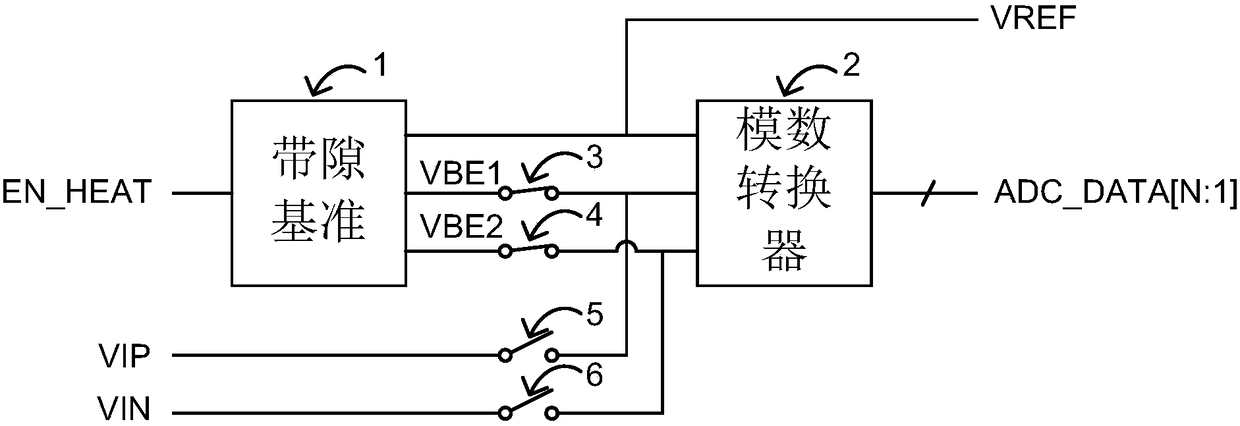

[0031] Such as figure 1 Disclosed is an integrated circuit for calibrating temperature drift of a bandgap reference voltage by self-heating, comprising a bandgap reference 1, an analog-to-digital converter 2, first, second, third, and fourth switches 3-6; the bandgap reference 1 is respectively The first and second switches 3 and 4 are connected to the analog-to-digital converter 2, one end of the third and fourth switches 5 and 6 is connected to the analog-to-digital converter 2, the other end of the third switch 5 is connected to the VIP end, and the fourth switch 5 is connected to the VIP end. The other end of the switch 6 is connected to the VIN end; the analog-to-digital converter 2 is connected to the triode junction voltage outputs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com