A kind of ceramic electrolyte material and preparation method thereof

A ceramic electrolyte and reaction technology, which is applied in the field of laser processing technology and energy materials, can solve the problems of difficult-to-synthesize materials, equipment, and high synthesis conditions, and achieve the effects of high raw material utilization, simple preparation methods, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

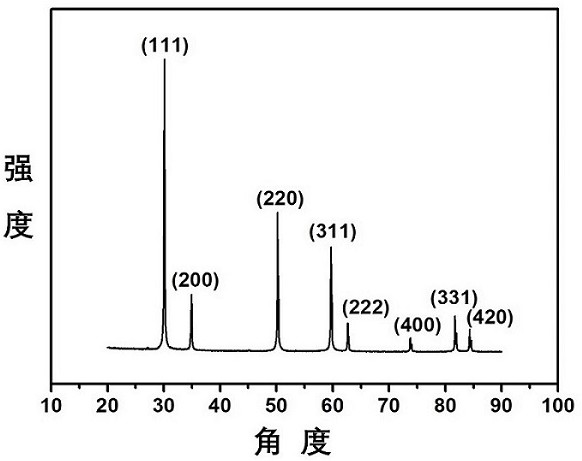

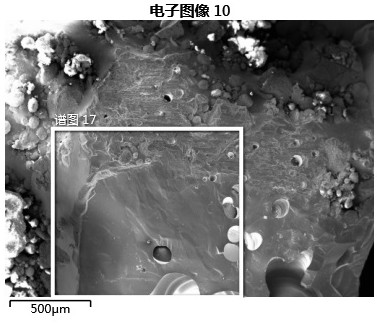

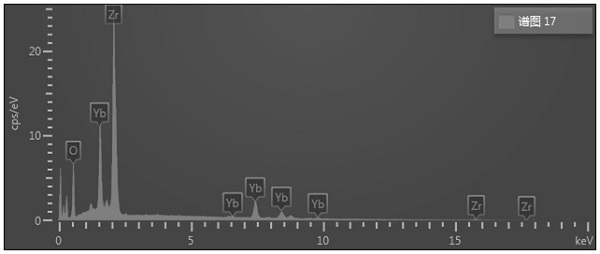

[0028] Oxide Yb of rare earth element Yb 2 o 3 Oxide ZrO with element Zr 2 According to the molar ratio Yb:Zr=2:8, calculate and weigh two kinds of oxide raw materials of corresponding mass respectively, and use ethanol as the ball milling medium, ball milling speed 400r / m, time 24h, fully and evenly mix to obtain Raw material mixture powder, the mixture powder obtained by ball milling is dried and ground in an oven at 80°C, the ground raw material mixture powder is compacted by a hydraulic press, the pressure is 8MPa, and the holding time is 5s, then placed in a copper crucible, using a semiconductor laser , the laser wavelength is 980nm, the laser sintering power is 300W, and the mixed raw materials in the crucible are sintered to cause a high-temperature solid-phase reaction of the raw material mixture, and the sintering time is 5 minutes to obtain Yb 2 Zr 8 o 19 Type ceramic electrolyte material, the material has a stable structure and does not undergo phase change bet...

Embodiment 2

[0030] Oxide Yb of rare earth element Yb 2 o 3 Oxide ZrO with element Zr 2According to the molar ratio Yb:Zr=2:8, calculate and weigh two kinds of oxide raw materials of corresponding mass respectively, and use ethanol as the ball milling medium, ball milling speed 400r / m, time 24h, fully and evenly mix to obtain Raw material mixture powder, the mixture powder obtained by ball milling is dried and ground in an oven at 70°C, and a PVA binder with a mass fraction of 8% is added to the uniformly ground powder for granulation and compaction. ℃, the heating rate is controlled at 1 ℃ / min, the holding time is 12 hours, and then placed in a copper crucible, using a semiconductor laser, the laser wavelength is 980nm, and the laser sintering power is 400W, sintering the mixed raw materials in the crucible to make the raw material mixture generate high temperature Solid state reaction, sintering time is 5min, and Yb is obtained 2 Zr 8 o 19 It is a relatively dense ceramic electrolyt...

Embodiment 3

[0032] Oxide Yb of rare earth element Yb 2 o 3 Oxide ZrO with element Zr 2 According to the molar ratio Yb:Zr=2:8, respectively calculate and weigh two kinds of oxide raw materials of corresponding mass, and use acetone as the ball milling medium, the ball milling speed is 400r / m, and the time is 24h, and fully and uniformly mix to obtain Raw material mixture powder, the mixture powder obtained by ball milling is dried and ground in an oven at 80°C, and a PVA binder with a mass fraction of 8% is added to the uniformly ground powder for granulation and compaction, and then low-power laser radiation Irradiate to remove the binder, the irradiation power is 30W, and the duration is 10min, and then placed in a copper crucible, using a semiconductor laser, the laser wavelength is 980nm, and the laser sintering power is 500W, sintering the mixed raw materials in the crucible to cause a high-temperature solid-state reaction of the raw material mixture , the sintering time is 3min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com