Resin touch screen, resin touch screen control panel, home appliance, and processing method

A control panel and touch screen technology, applied in the fields of instruments, electrical digital data processing, computing, etc., can solve the problems of fragility, inability to human-computer interaction, and high glass surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

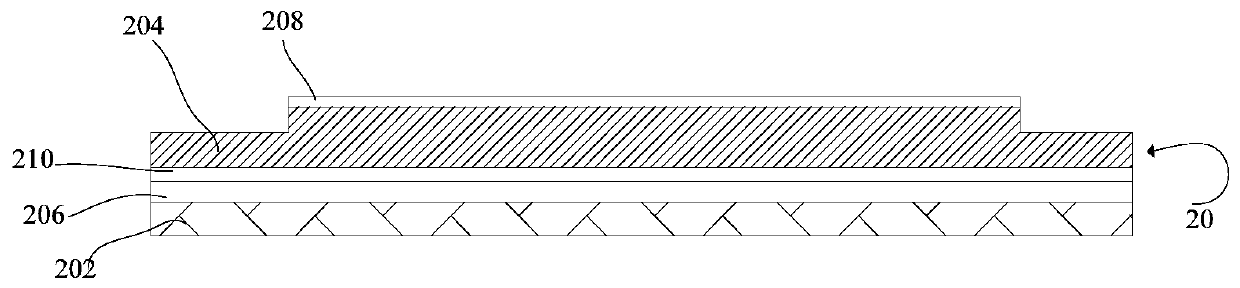

[0078] In this specific example, if figure 1 As shown, the layers of the resin touch screen 20 from top to bottom are: UV hardening layer 208, resin touch screen body 204, ink printing layer 210, optical double-sided adhesive layer and touch flexible circuit board. The thickness of the resin touch screen body 204 is 2.65 mm, and the thickness of the UV hardening layer 208 is 0.013 mm.

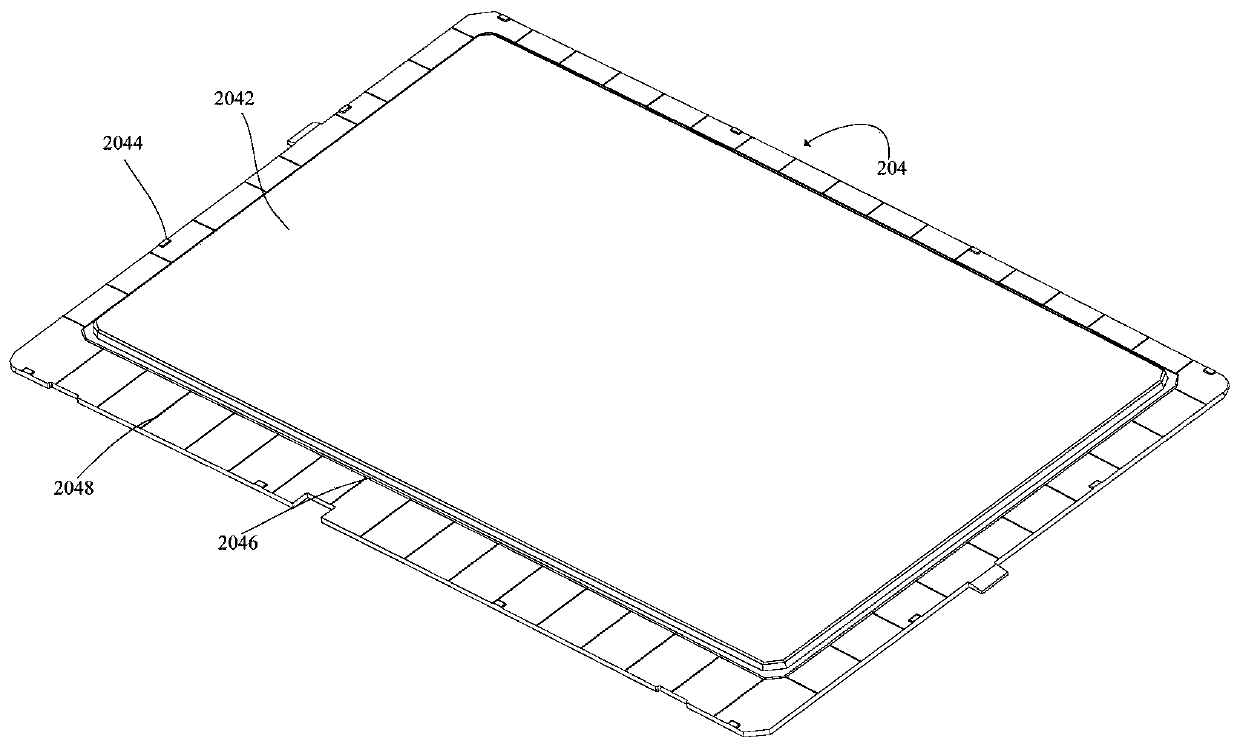

[0079] Such as figure 2 As shown, the number of bosses 2044 is 12, and the height is 0.2 mm; the number of ribs 2048 is 52; the height of steps 2046 is 0.15 mm. When bonding the resin touch screen 20 and the control panel 22, use a glue machine to apply glue along the line formed by the center of the convex rib 2048 of the resin touch screen 20. The glue used is ultraviolet curable resin glue. The resin display screen 10 is turned upside down and pressed onto the hollowed-out rectangular area of the control panel 22 . The surrounding bosses 2044 reserve a space of 0.2 mm between the resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com