Assembly and disassembly device for stator and rotor of radial permanent magnet motor

A permanent magnet motor, stator and rotor technology, used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as manual assembly and disassembly difficulties, achieve smooth motor assembly and disassembly process, improve qualification rate and Effectiveness of work efficiency and injury avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

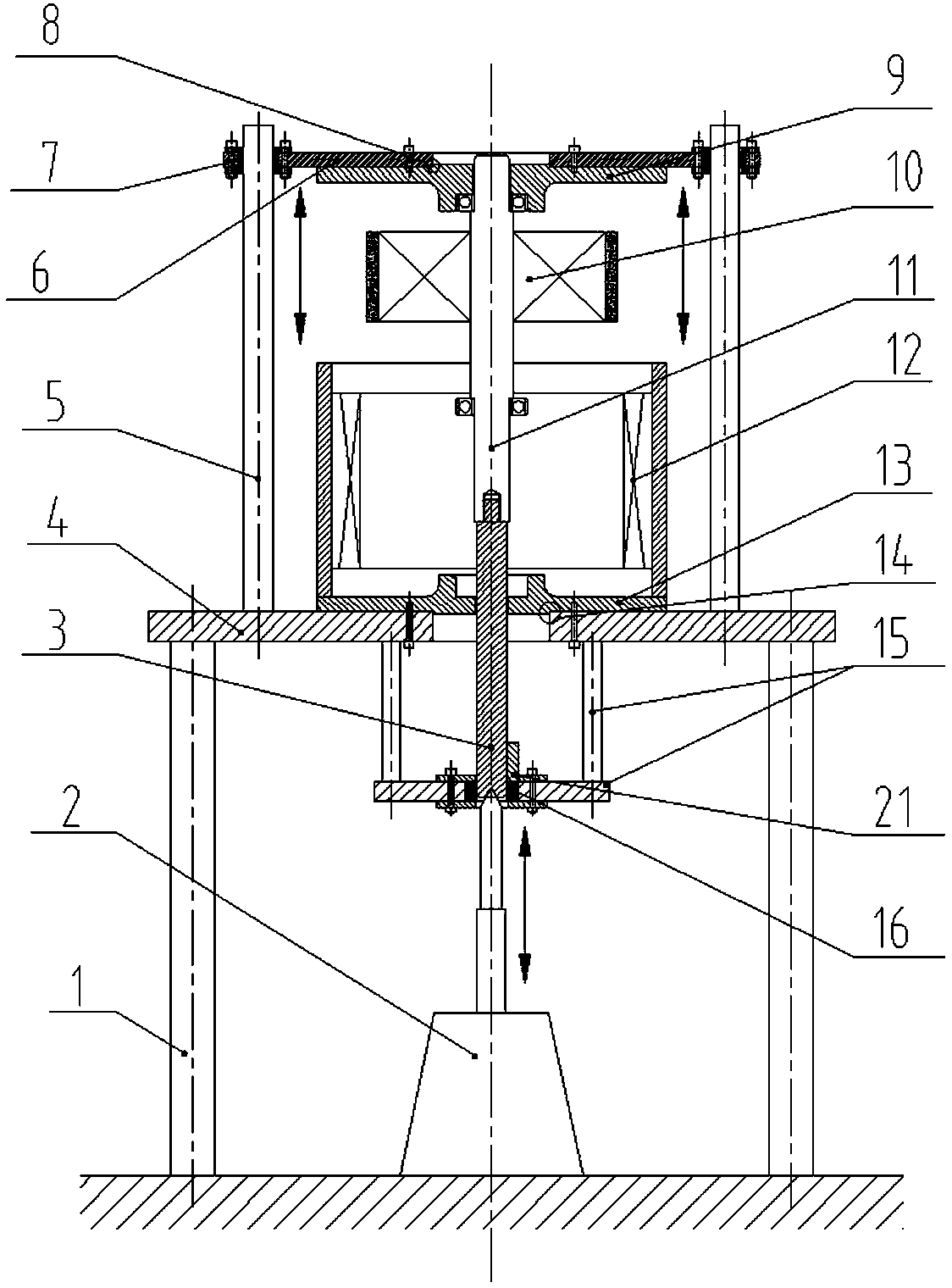

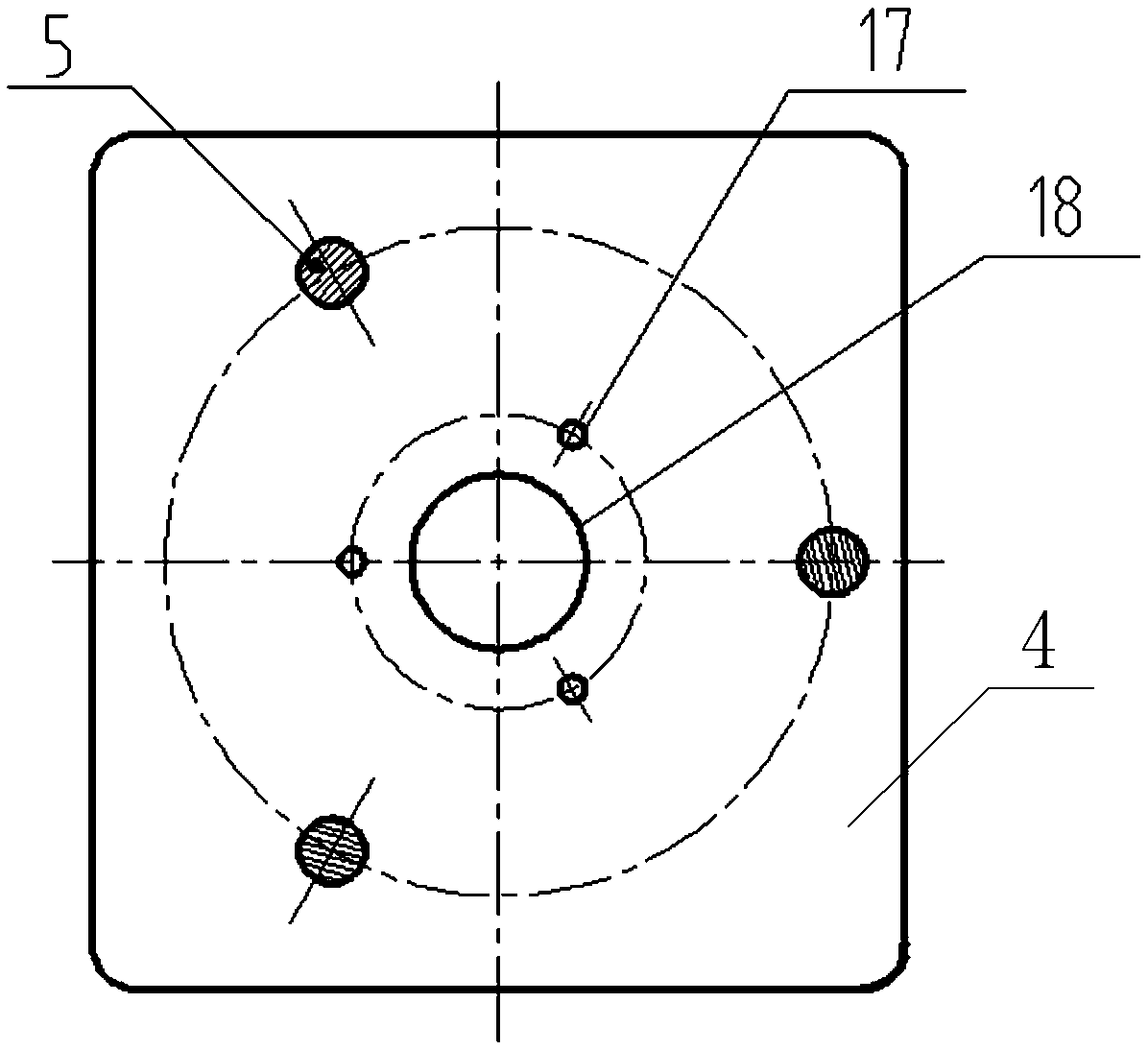

[0039] Before operation, the following preparatory work needs to be done. The front end cover 13 of the motor is processed to fit the seam f 14 and the internal thread. 14 and the positioning through hole b18 cooperate to locate the axis of the motor casing 12, and the bolt is connected to the internal thread on the front end cover through the connection through hole a, and is used to fix the motor front end cover 13 and the casing 12 on the fixed platform 4.

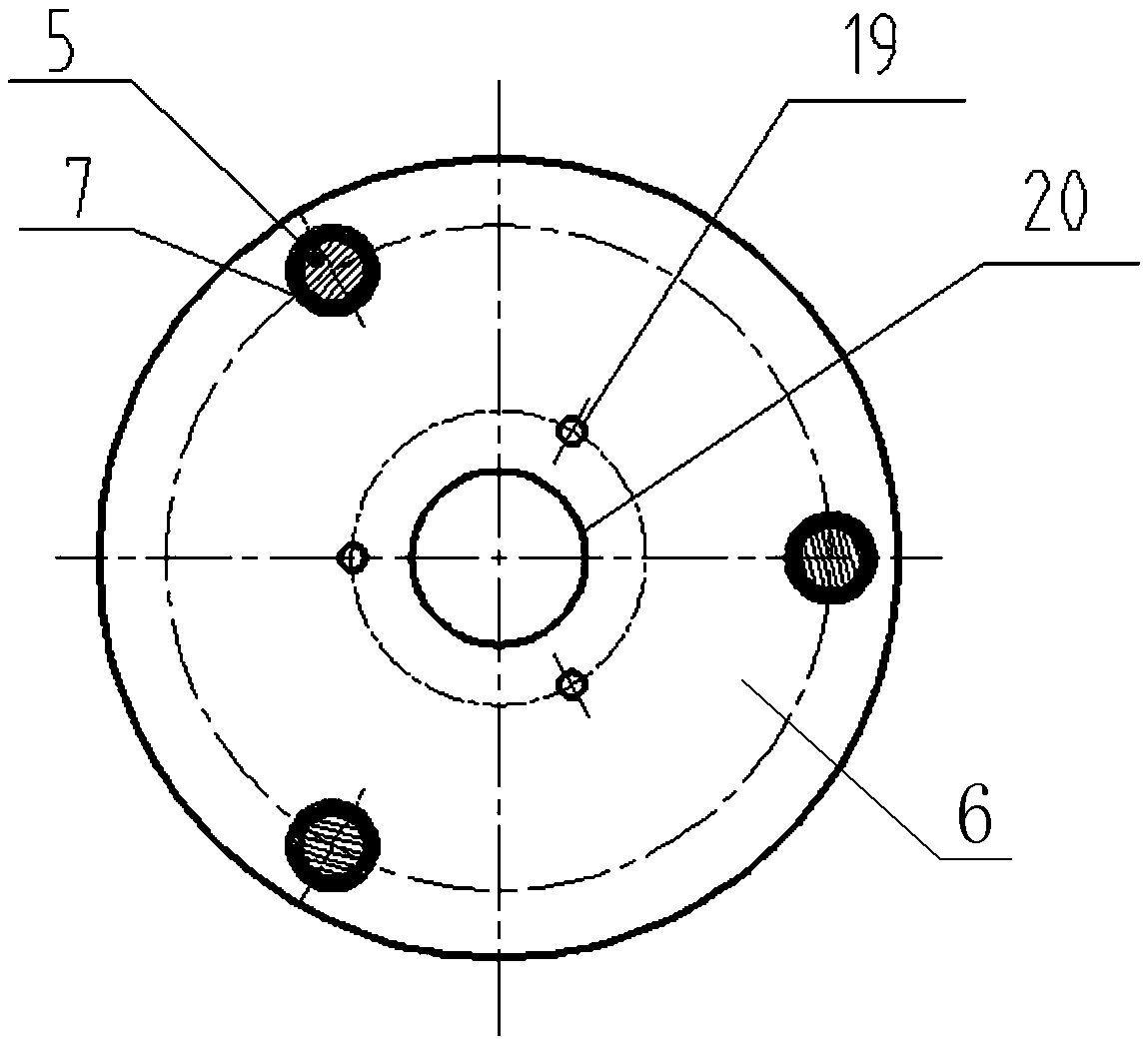

[0040]The motor rear end cover 9 is processed with the matching seam e 8 and internal thread, the motor rear end cover 9 is assembled with the motor bearing and the permanent magnet motor rotor 10, the matching seam e 8 is matched with the positioning through hole d 20, and the bolt passes through After connecting the through hole c, it is connected with the internal thread on the rear end cover, which is used to fix the motor rear end cover 9 and the rotor 10 under the rotor positioning plate 6 . The 11-axis rising end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com