3D object ink-jet printing method and system

An inkjet printing and printing system technology, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the manufacturing cost of printers, increasing the footprint of printers, and easy clogging of print head nozzles, etc., to achieve The effect of reducing the number of printing channels, improving utilization, and reducing the risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

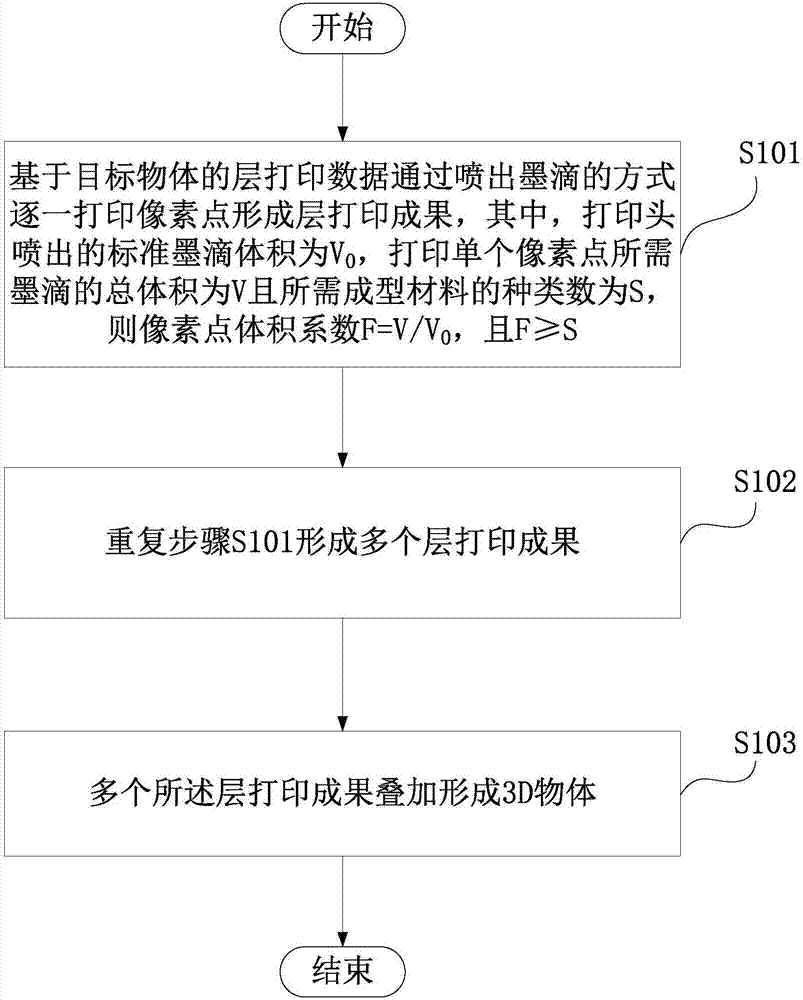

[0056] figure 1 It shows a method for inkjet printing of 3D objects according to a specific embodiment of the present invention. A 3D object is made by layer-by-layer printing, including the following steps:

[0057] Execute step S101, based on the layer printing data of the target object, print pixels one by one by ejecting ink droplets to form a layer printing result, wherein the standard ink droplet volume ejected by the print head is V 0 , the total volume of ink droplets required to print a single pixel is V and the number of types of molding materials required is S, then the pixel point volume factor F=V / V 0 , and F≥S. Specifically, the layer printing data includes layer structured data and layer unstructured data, both of which are a set of data with spatial coordinates, and the layer unstructured data is also related to the molding material For example, if the molding materials are materials of different colors, then the layer unstructured data is color value data; f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com