Self-balancing cable net structure capable of moderating wind load

A cable-net structure and self-balancing technology, applied in special structures, building components, etc., can solve the problems of difficult structural design of rigid structures, consuming a lot of manpower and equipment resources, disadvantages of self-weight and steel consumption, etc., to avoid tension. The effect of construction work, shortening the construction period, and reducing the cost of construction measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

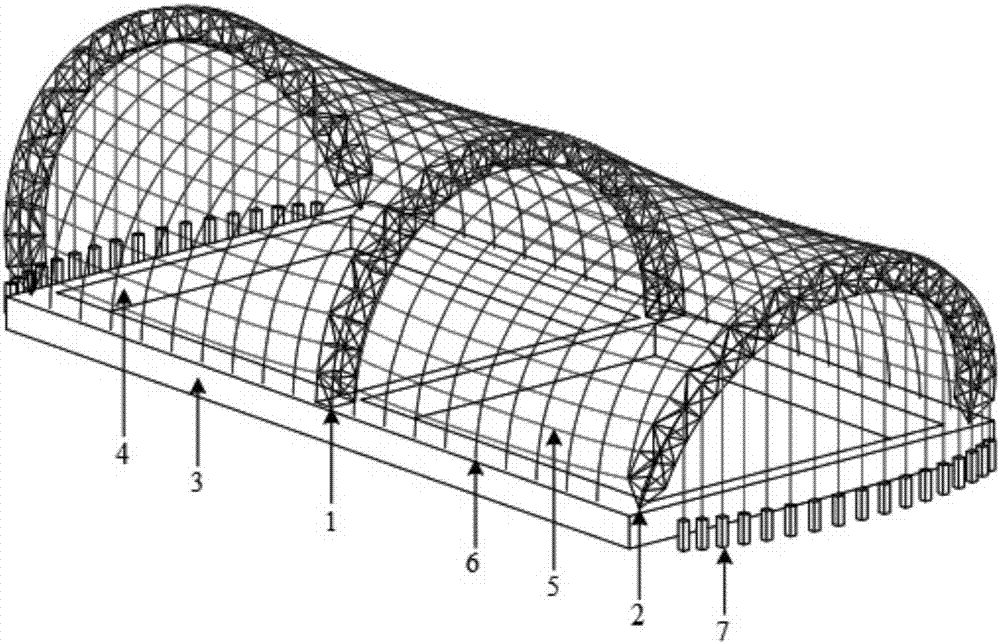

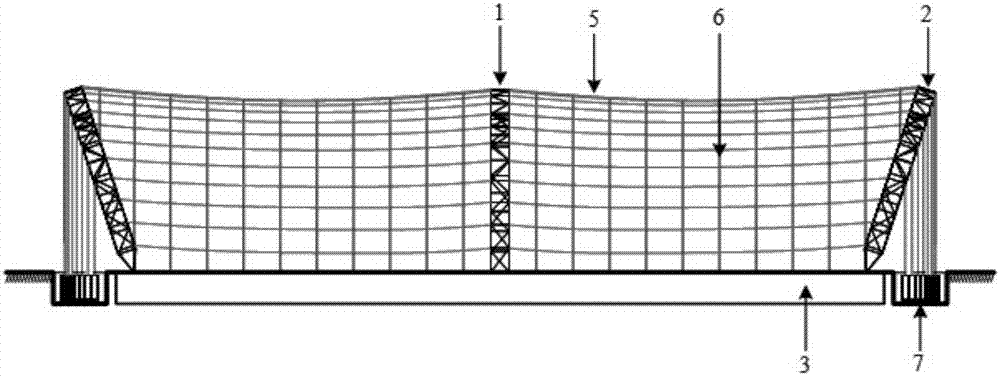

[0019] Attached below Figure 1~6 , to describe the implementation of the present invention in detail.

[0020] Such as figure 1 , 2 As shown, a self-balancing cable-net structure capable of relieving wind loads includes the following components:

[0021] 1——steel arch in the middle;

[0022] 2——end steel arch;

[0023] 3——longitudinal ground beam;

[0024] 4——horizontal ground beam;

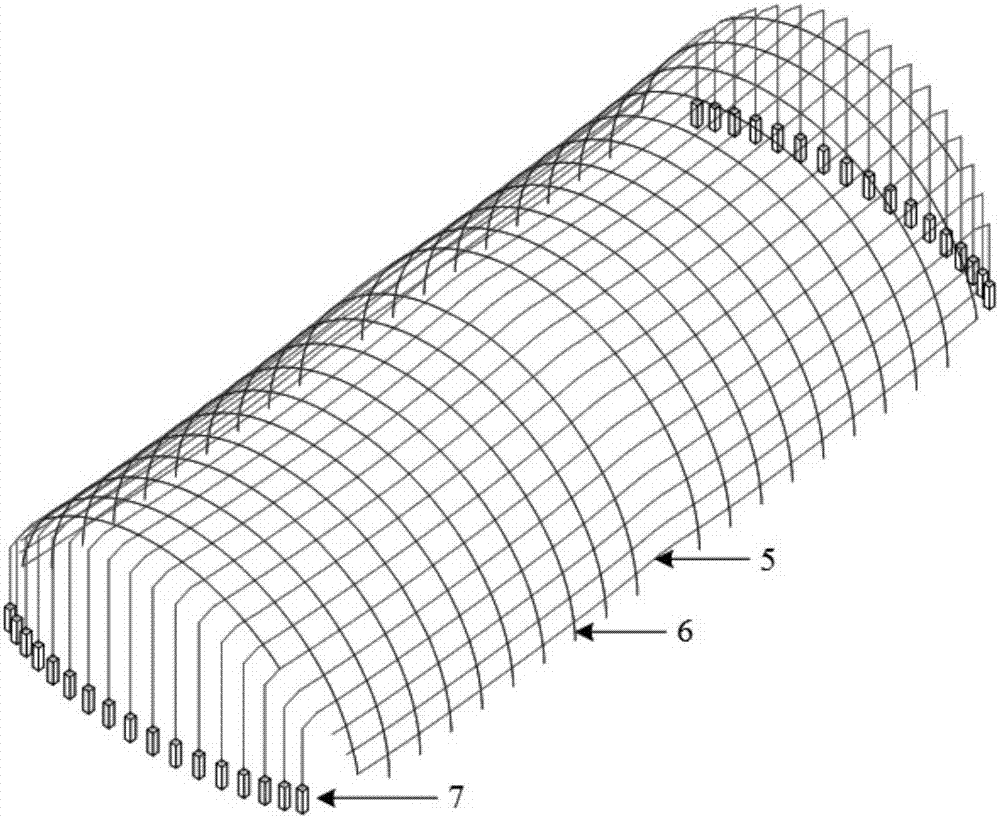

[0025] 5 - load-bearing cable;

[0026] 6——stabilizing cable;

[0027] 7 - counterweight;

[0028] Such as figure 1 , 2 , 3, a self-balancing cable net structure that can moderate wind loads consists of a central steel arch 1, an end steel arch 2, a longitudinal ground beam 3, a transverse ground beam 4, load-bearing cables 5, stabilizing cables 6 and counterweights 7 composition. The middle steel arch 1 is set in the middle of the structure longitudinally, and can be set in single or multiple lanes according to the actual structure length; the end steel arch 2 is installed obliquely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com