Construction method for broaching-brushing of winze

A construction method, the technology of the sky-sliding shaft, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of slow construction speed, slow expansion speed, and many cycles, so as to achieve fast expansion speed, cost saving and step-by-step simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

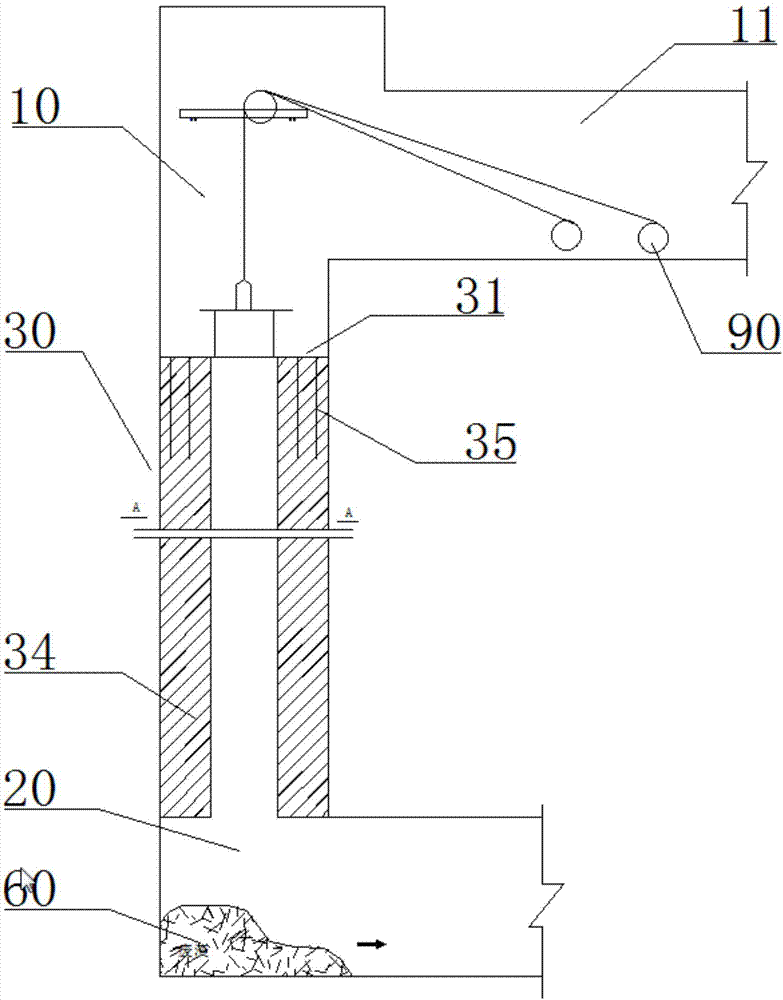

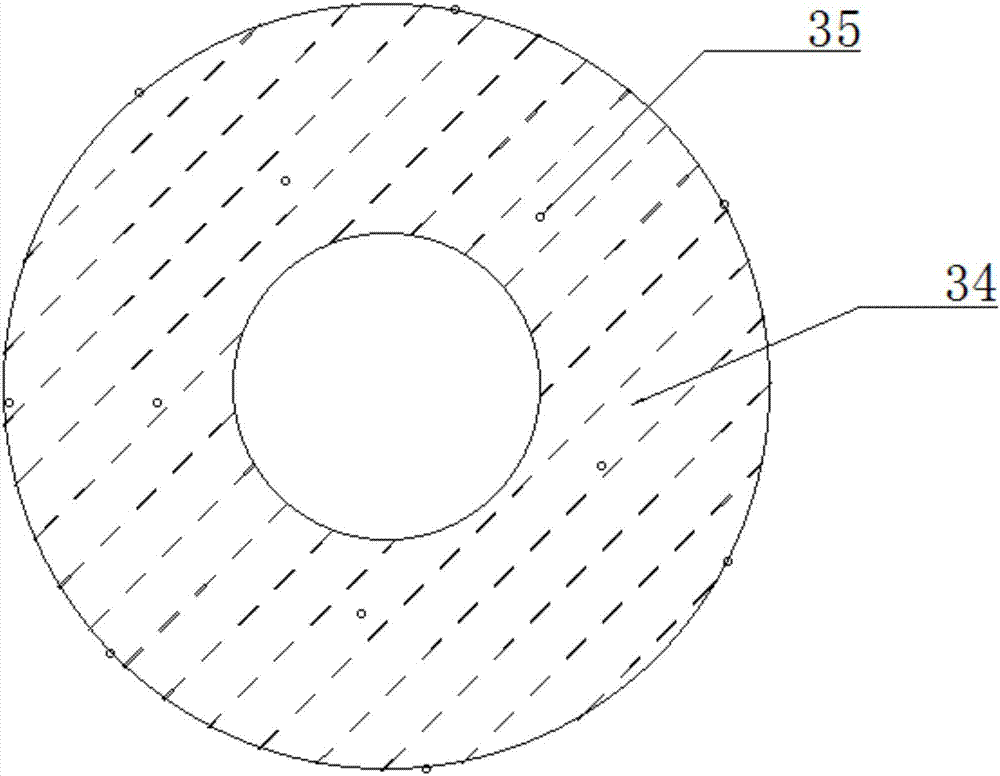

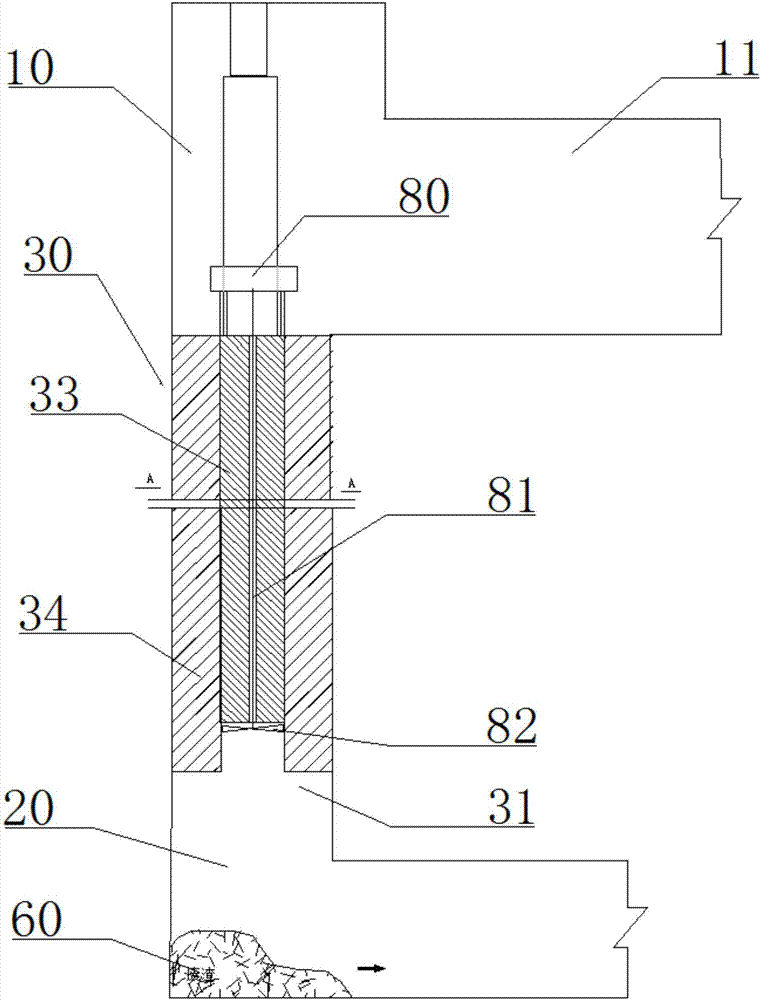

[0029] Such as Figure 3-6 As shown, the present invention provides a kind of construction method of brushing sky chute, and this method comprises the following steps: the first step, as Figure 3-4 Shown, vertically go out pilot hole 32 downwards along skyway 30 centerlines; Second step, as Figure 3-4 As shown, the reaming area 33 around the pilot hole 32 is reamed from bottom to top by a raise drilling machine 80; the third step, as Figure 5-6 As shown, after the reaming, the blast hole 35 is arranged in the brush expansion area 34 around the hole expansion area 33, and the blast hole 35 is blasted from bottom to top to expand the brush expansion area 34, and from the brush expansion area 34 Expand to the well wall of Tianliujing 30.

[0030] The present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com