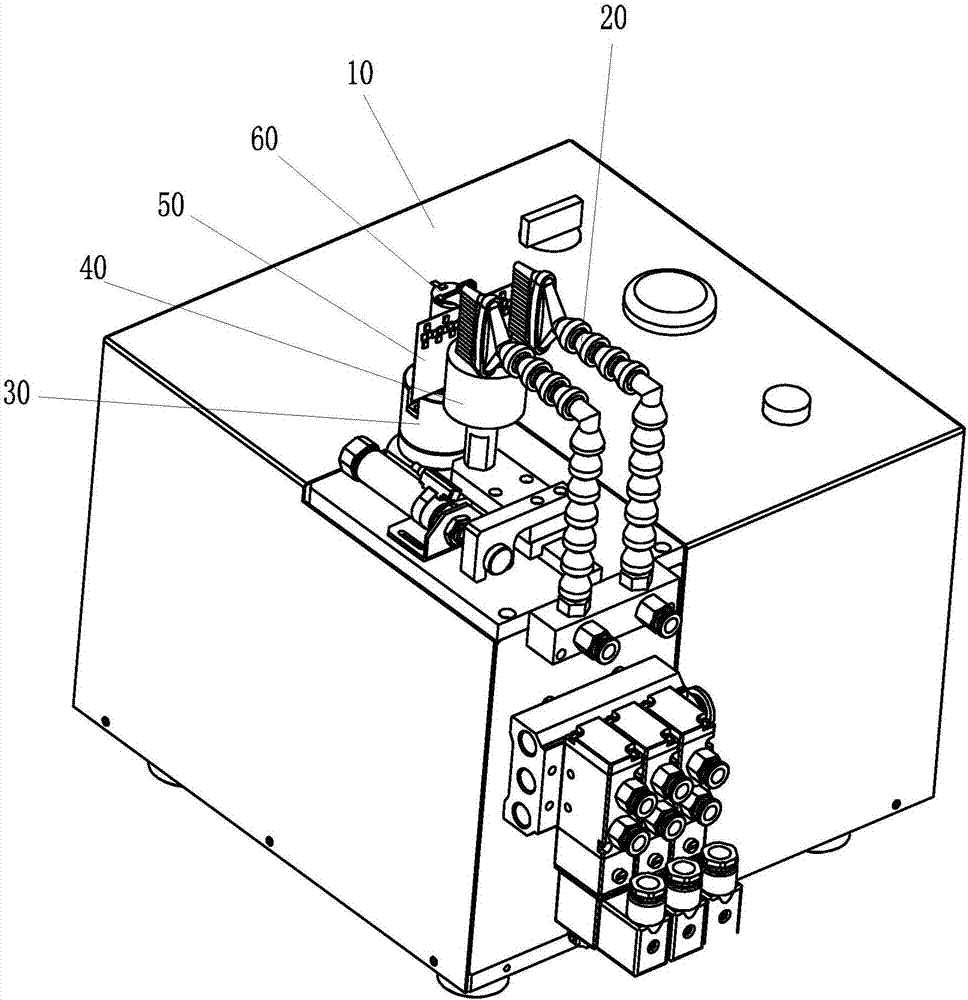

Flexible board light source surface-mounting method and device

A mounting device and light source technology, which is applied in the direction of light source, lighting device, light source fixing, etc., can solve the problems of light bead damage, easy to touch the light source with hands, and difficult operation efficiency, so as to improve the placement yield and placement efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

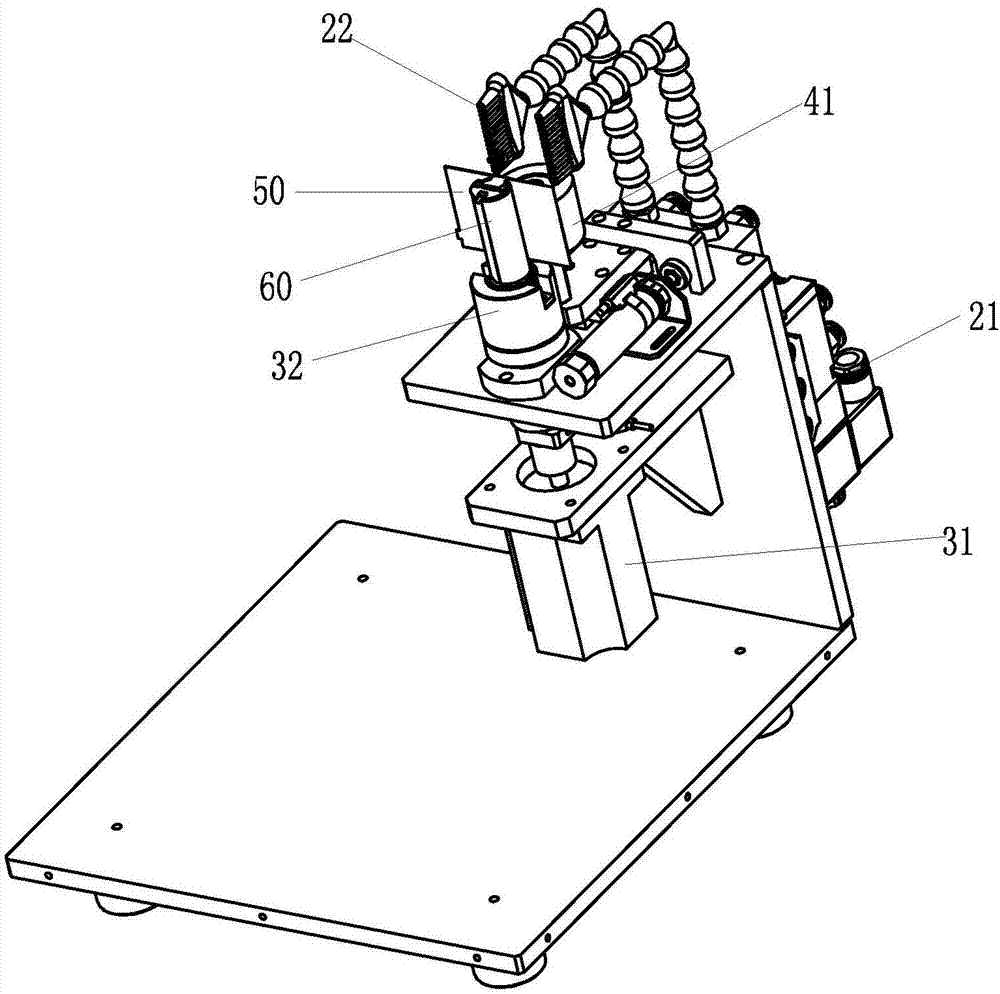

[0023] A mounting method for a flexible board light source, comprising the following steps:

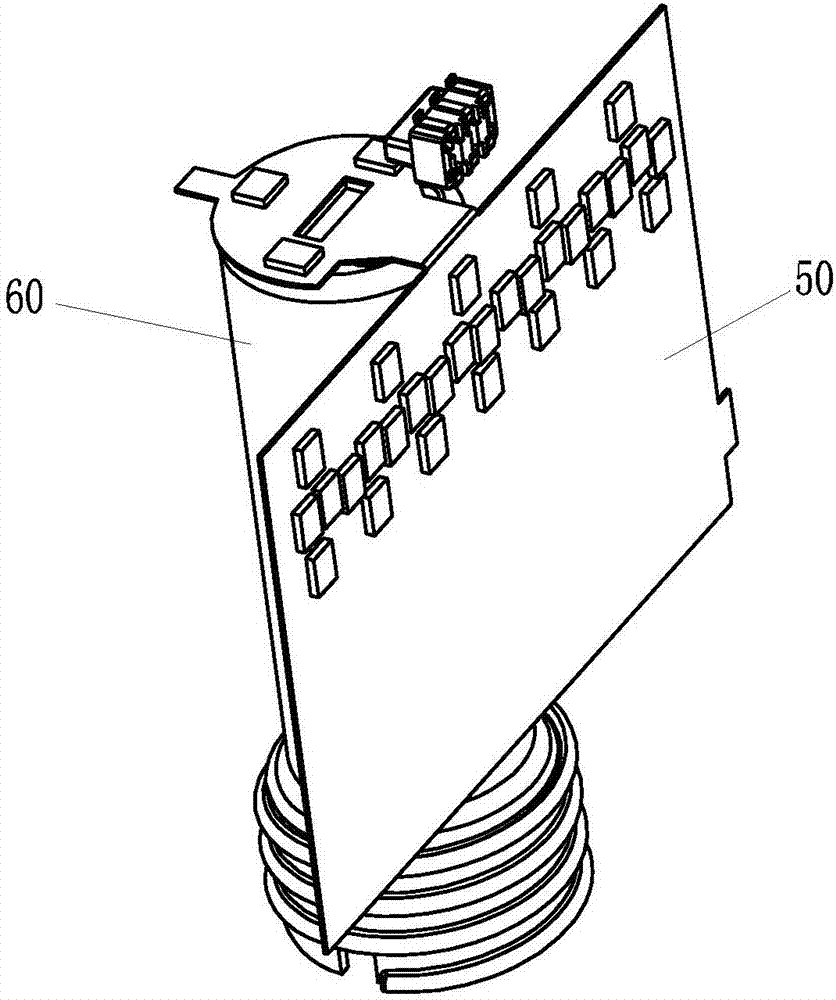

[0024] Step 1, fixedly connect the flexible board light source to the light source stem, and the adhesive surface of the soft board light source faces the outer surface of the light source stem;

[0025] Step 2, attaching the fixedly connected flexible board light source and the light source stem to the rotating device;

[0026] Step 3, compress the flexible board light source and the light source stem with the pressing device;

[0027] Step 4, turn on the blowing device and blow the gas to the soft board light source so that the soft board light source is close to the cylindrical surface of the light source stem, and at the same time start the rotation device to drive the light source stem and the soft board light source to rotate. Under the pressing action of the light source, the soft board light source is bent and tightly attached to the cylindrical surface of the light source st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com