Ultra-short bolt wedge load testing clamp and experimental method applying same

A technology of load test and bolt, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of insufficient clamping section, inability to carry out tests, space occupied by wedge pads, etc. The effect of convenient installation, shortened test period and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

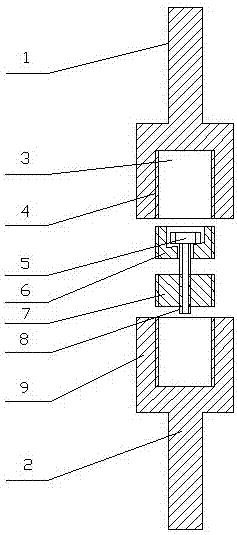

[0025] As shown in the figure, the specific implementation method is as follows:

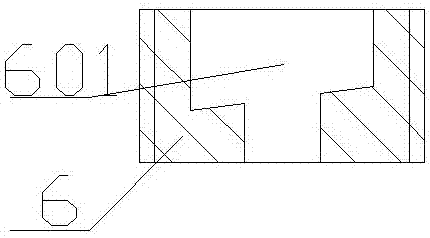

[0026] A clamp for ultra-short bolt wedge load test, comprising a first main clamp 4 and a second main clamp 9, the first main clamp 4 and the second main clamp 9 are cylindrical structures with the same structure, the first main clamp One end of the clamp 4 is connected with the first clamping part 1 for connecting the first main clamp 4 to the clamp on the tensile testing machine, and the end of the first main clamp 4 away from the first clamping part 1 is dug with a second A threaded counterbore 3, one end of the second main clamp 9 is connected with the second clamp 2 for connecting the second main clamp 9 to the upper and lower jaws of the tensile testing machine, the first clamp 1 and The second clamping part 2 is a rectangular parallelepiped clamping rod (or splint), and the end of the second main clamping fixture 9 away from the second clamping part 2 is dug with a second threaded counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com