Cable jacket

A technology of cable sheath and sheath, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of slippery inner wall of the outer insulating sheath, unstable electrical performance of the cable, single performance of the outer insulating sheath, etc., to increase friction Coefficient, prevent relative sliding, effect of blocking influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Example: a cable sheath

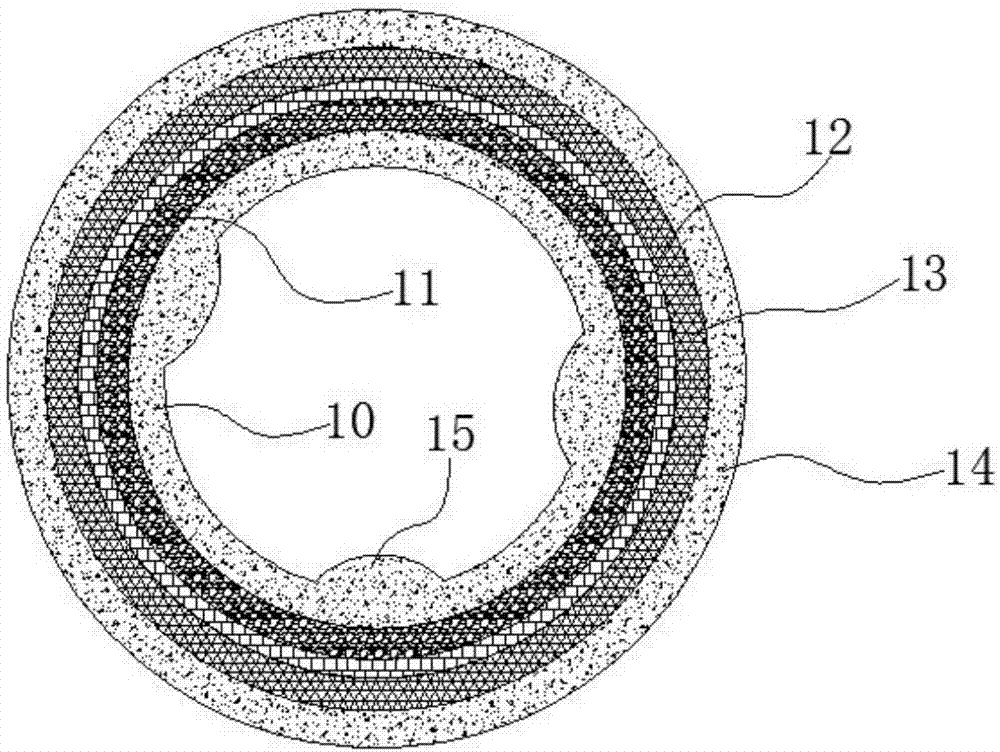

[0019] see figure 1 , wrapped on the outermost layer of the cable, the sheath includes a sheath body 1 .

[0020] Wherein, the sheath body 1 is composed of an inner insulating layer 10, a fireproof layer 11, a gauze layer 12, a shielding layer 13, and an outer insulating layer 14. The inner insulating layer 10, the fireproof layer 11, the gauze layer 12, the shielding Layer 13 and outer insulating layer 14 are provided with an adhesive between each other. The thickness ratio of the inner insulating layer 10 , the fireproof layer 11 , the gauze layer 12 , the shielding layer 13 and the outer insulating layer 14 is 2˜4:2˜4:1:1˜3:2˜4. And the thickness of the mesh layer 12 is 0.3mm. In this embodiment, specifically, the thickness ratio of the inner insulating layer 10 , the fireproof layer 11 , the gauze layer 12 , the shielding layer 13 and the outer insulating layer 14 is 3:3:1:2:3.

[0021] Three helical ribs 15 protrude from the inner wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com