Chemically treated hair pulling machine

A mainframe and mainframe technology, applied in wigs, clothing, applications, etc., can solve the problems of low efficiency, high labor intensity, uneven amplitude, etc., and achieve the effect of reducing labor intensity, improving production efficiency, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above-mentioned content of the present invention will be further described in detail by the following examples.

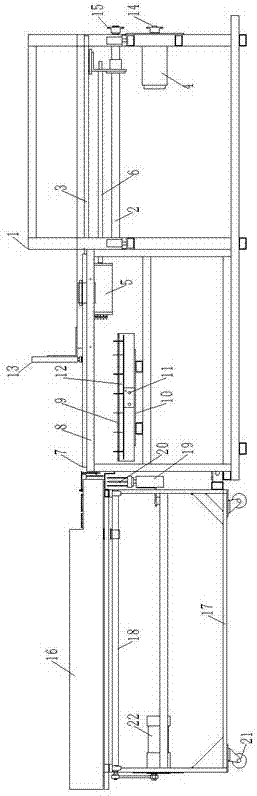

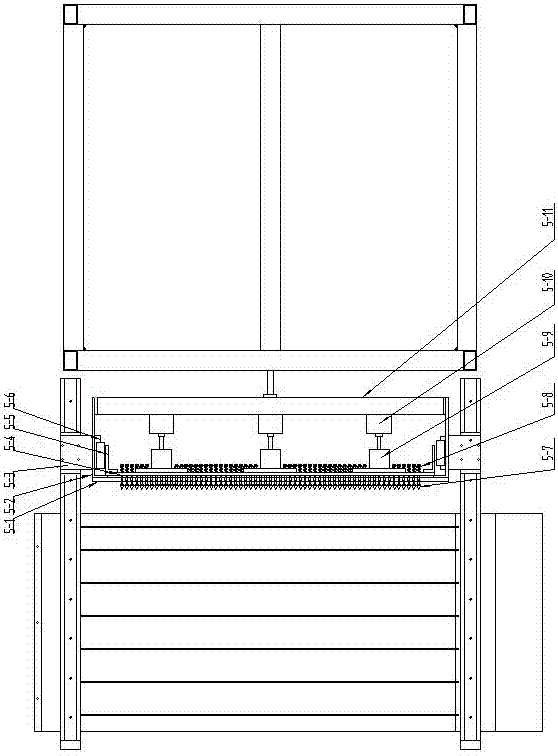

[0026] The cooked hair pulling machine includes a hair feeding unit and a main unit. The main unit is mainly composed of a main frame 1, a main drive ball screw 2, a main drive ball screw guide rail 3, a main motor 4, a hair pulling head assembly 5, a main The connecting rod 6, the hair pulling head guide rail 7, the support frame 8, the hair extension table 9, the hair extension table support plate 10, the hair setting cylinder 11, the hair setting needle plate assembly 12 and the hair pressing cylinder 13 are constituted, wherein the support frame 8 is arranged on the host On one side of the frame 1, the hair-pulling head guide rail 7 is arranged in parallel on the support frame 8, the hair-pulling head assembly 5 is connected with the slider on the hair-pulling head guide rail 7 and is connected with the main drive ball screw 2 through the main connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com