Bone bolt and manufacturing process of bone bolt

A technology of bone bolts and bolts, applied in the field of medical devices, can solve problems such as affecting the healing time of bones and affecting the healing effect, and achieve the effect of accelerating the healing speed and good connection firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

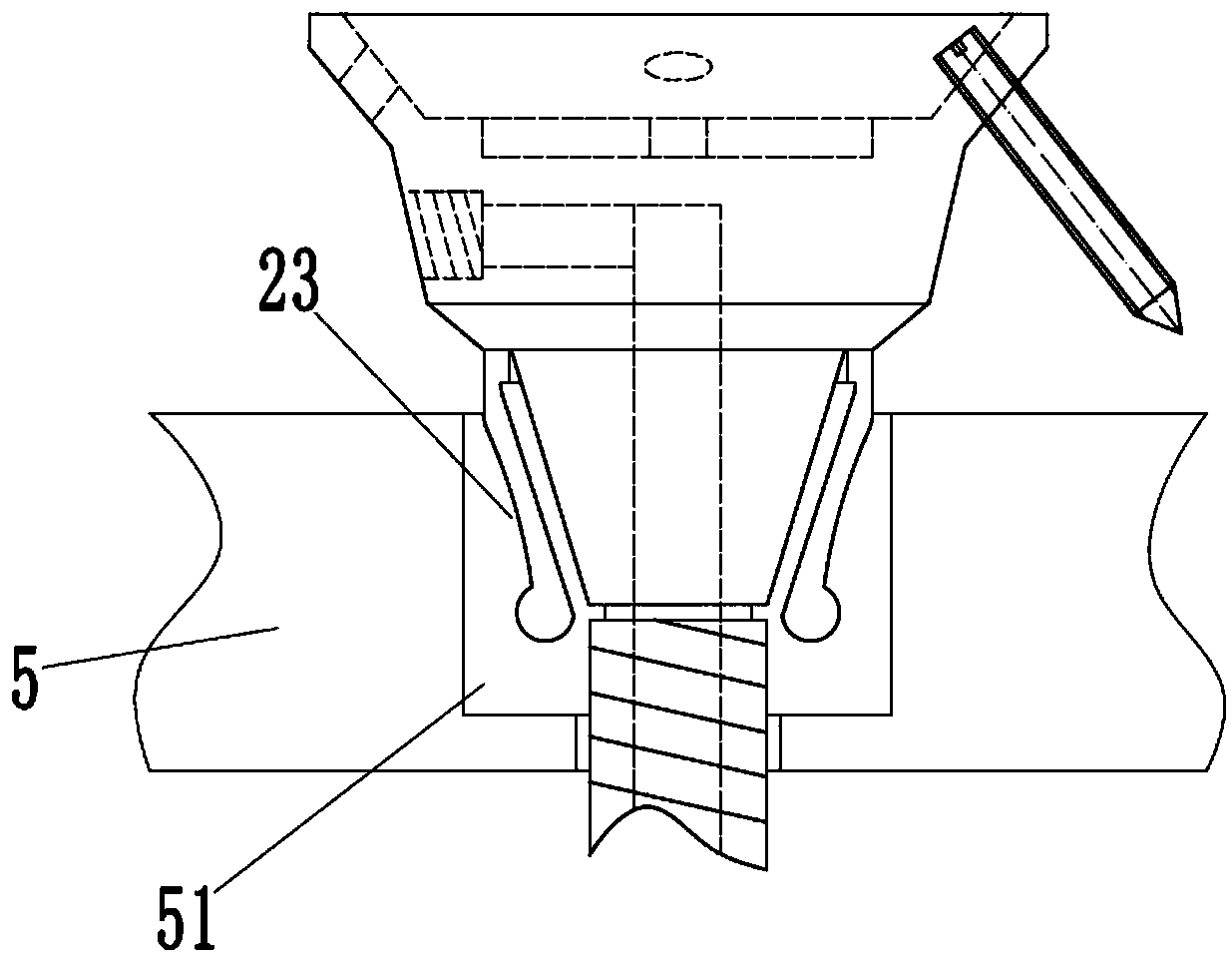

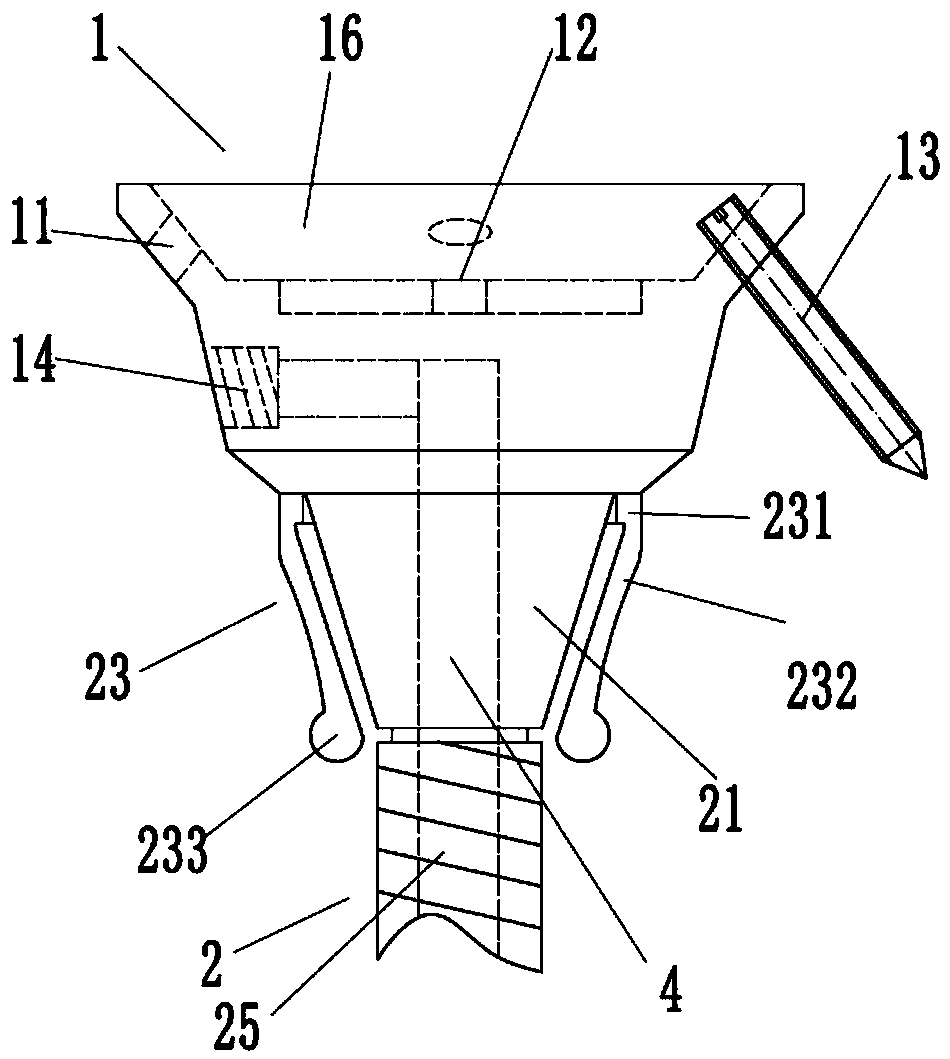

[0037] refer to Figure 1 to Figure 5 ,Such as figure 1 and figure 2 The shown bone bolt is made of Ti6AI4V titanium alloy material, comprising: a bolt cap 1 and a bolt shaft 2, a groove 16 is arranged on the upper end surface of the bolt cap 1, and a groove 16 is arranged on the bottom surface of the groove 16. There is a cross sinking groove 12, the cross sinking groove 12 is used for the installation of the bone bolt, the side wall of the groove 16 is provided with a plurality of annular first through holes 11 uniformly arranged, and the first through holes The axis of 11 is arranged obliquely, and an adjustment screw 13 is also provided on the bolt cap 1, and one end of the adjustment screw 13 passes through the first through hole 11 and connects with the connecting plate 5 to adjust the offset angle of the axis of the bone screw, Make the end face of the connected broken bone close to the end face of another broken bone to be healed together to speed up the healing spe...

Embodiment 2

[0043] A manufacturing process for the bone bolt described above, the manufacturing steps comprising:

[0044] Step S01: making the bolt cap 1;

[0045] Step S02: making the frustum section 21 and the thread section 25 in sequence;

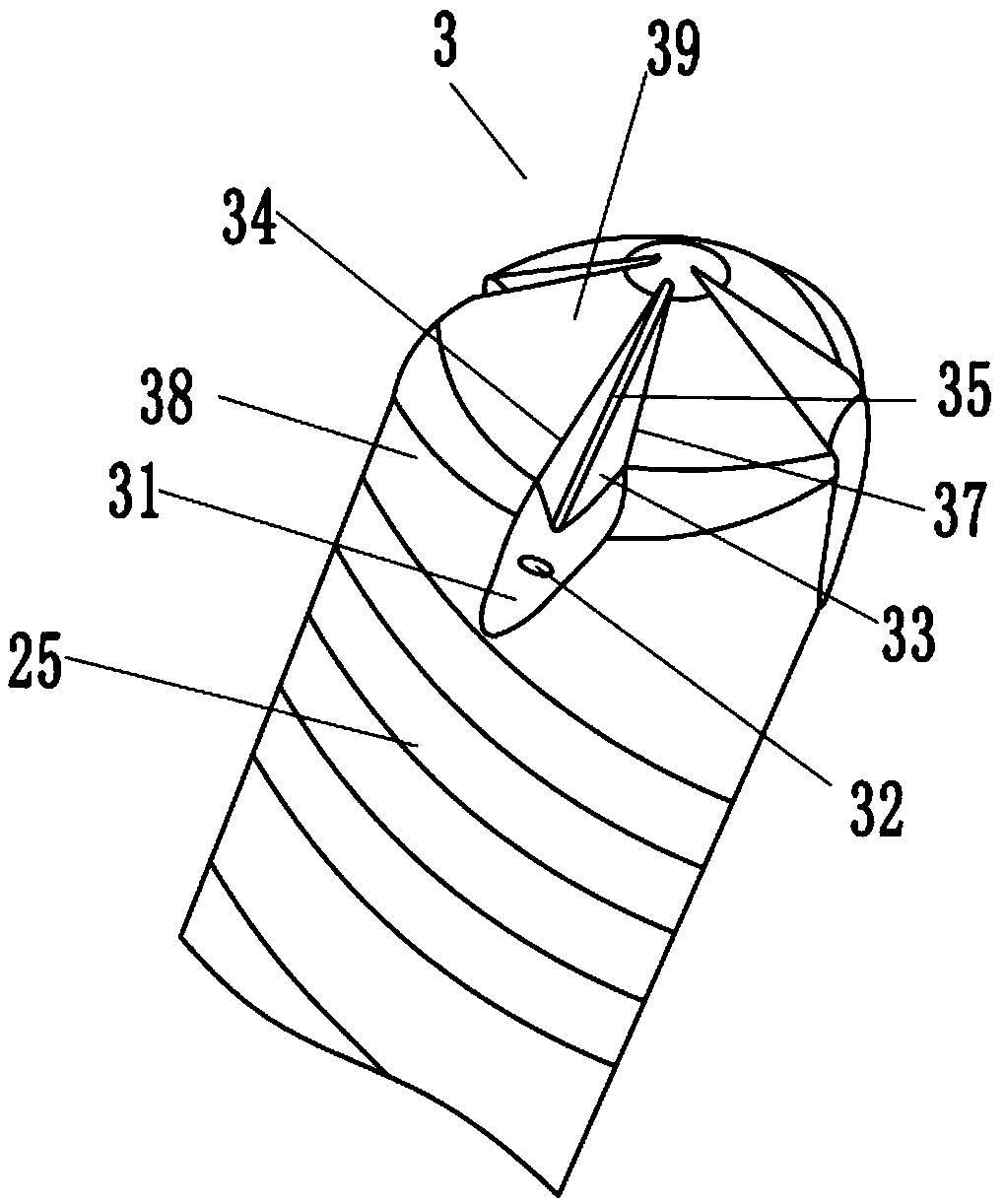

[0046] Step S03: making the cylindrical section 38 and the conical section 39 in sequence;

[0047] Step S04: Complete the groove 16, the cross sink groove 12 and several first through holes 11 on the bolt cap 1, wherein the angle between the axis of the first through hole 11 and the axis of the bolt cap 1 is 30°~60°; preferably, the included angle between the axis of the first through hole 11 and the axis of the bolt cap 1 is 30°;

[0048] Step S05: cutting the chip flute 31 and the cutting flute 35, the chip flute 31 and the cutting flute 35 are both in a spiral shape; the cutting flute 35 is processed to form the main cutting edge 37 and the auxiliary cutting edge 34, The cutting cone angle of the main cutting edge 37 is 60-80°, and the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com