Wind wheel roller press

A rolling machine and wind wheel technology, applied in the direction of metal processing equipment, etc., can solve the problems of not reaching the design size, high product scrap rate, low assembly stability, etc., to improve assembly quality, low wind wheel defect rate, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

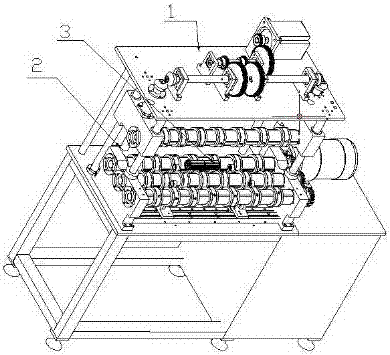

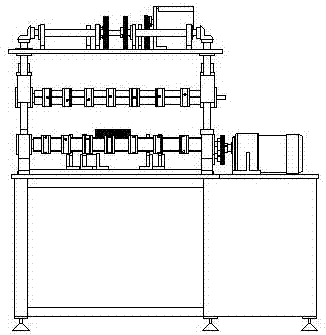

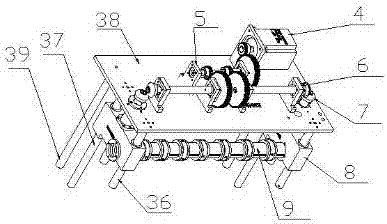

[0036] Example 1, see figure 1 —— Figure 6 , a wind wheel rolling machine, comprising a frame, an upper rolling wheel mechanism 1 and a lower rolling wheel mechanism 2, the lower rolling wheel mechanism 2 is arranged on the frame table, and the lower rolling wheel mechanism 2 is provided with The upper rolling wheel mechanism 1 and the lower rolling wheel mechanism 2 include a lower rolling wheel device 11, a gear seat 12, an axial limit device 13 and a driving device for driving each lower rolling wheel device 11 to rotate, and the two sides of the frame table are A gear seat 12 is provided, and the gear seat 12 includes a bottom plate and two side plates, and an axial limit device 13 is provided for sliding on the bottom plate, and at least two sets of lower rolling wheel devices 11 are installed between the two side plates; the upper rolling wheel mechanism 1 includes machine plate 38, screw seat 8, upper rolling wheel device 9, short guide post 36, long guide post 37 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com