Water pipe assembling device

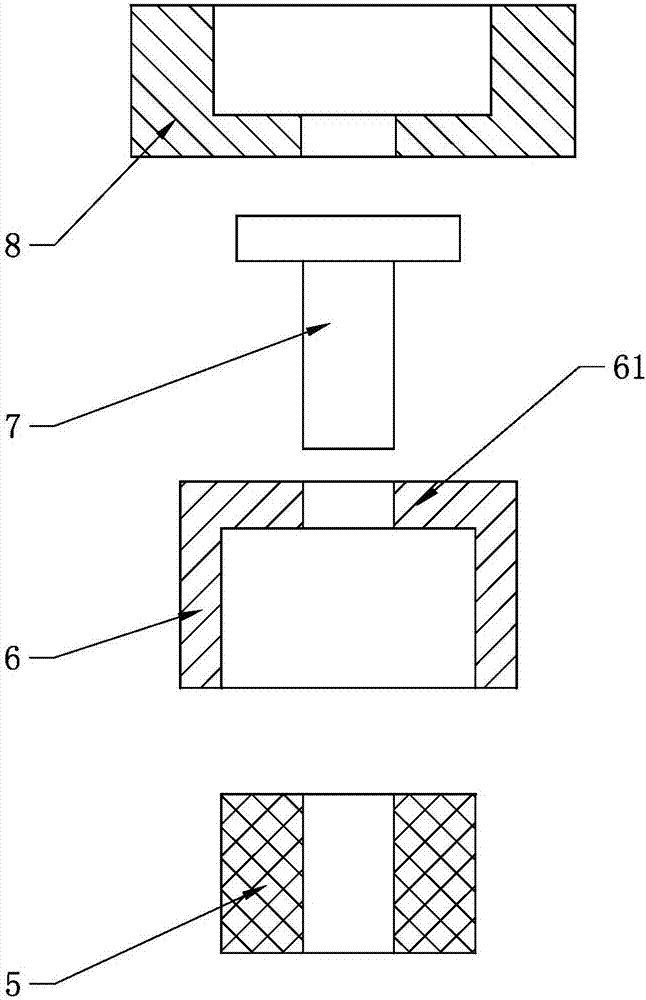

A technology for assembling devices and water pipes, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as easy gaps, different matching lengths between hose 5 and bushing 6, and insufficient connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

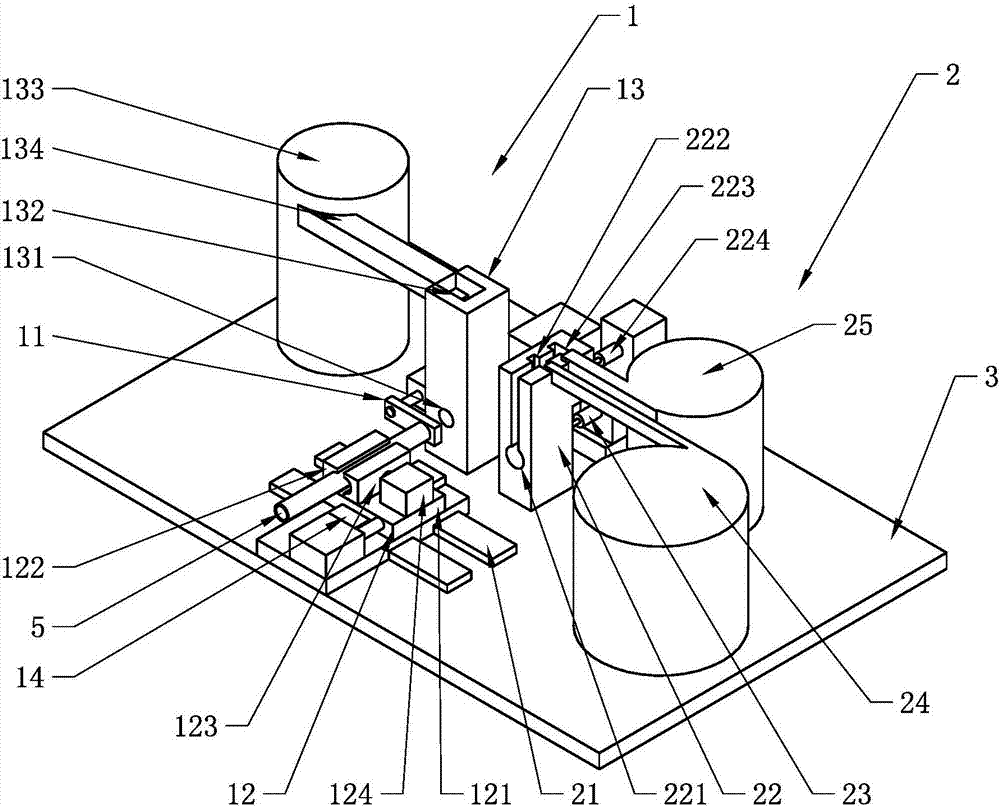

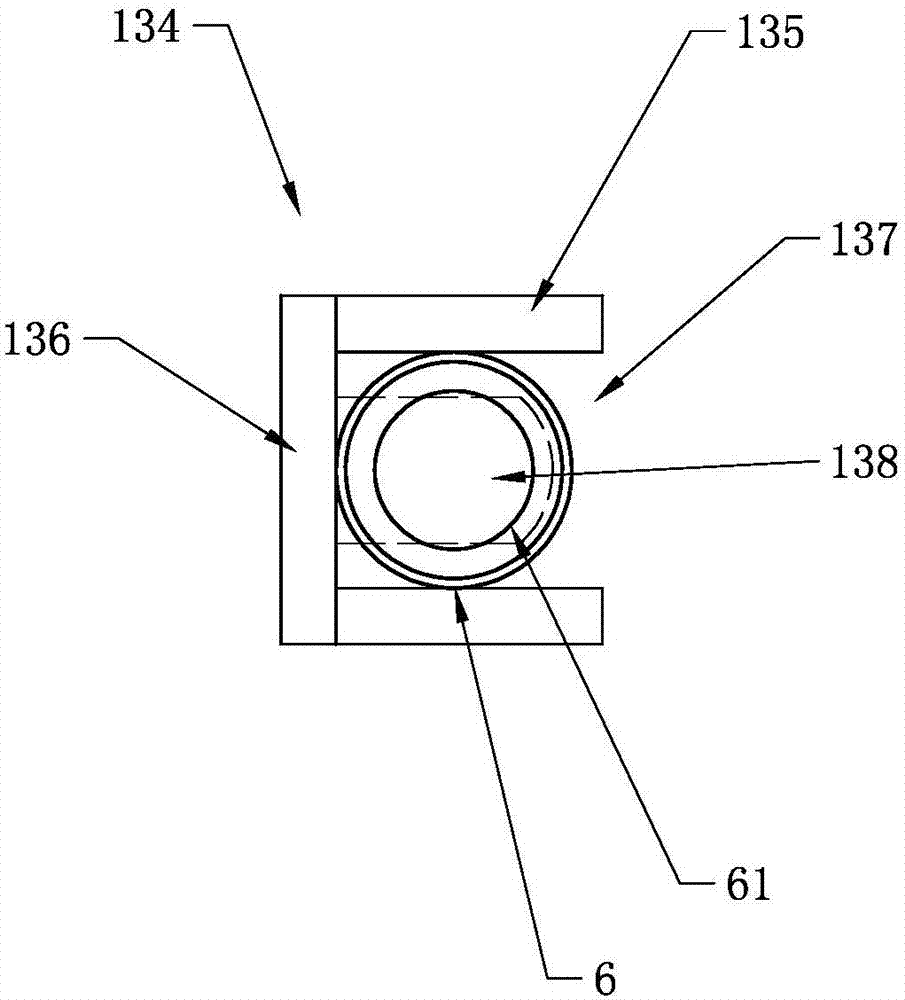

[0029] Such as image 3 As shown, the feeding guide rail 134 includes a first bottom plate 135, a first baffle plate 136 arranged on the side of the first bottom plate 135 facing away from the vibrator body, the first bottom plate 135 is provided with a first opening 137, and the width of the first opening 137 is larger than The outer diameter of the bushing 6, the opening direction of the first opening 137 faces the side of the vibrator body, the first opening 137 is provided with a first cantilever 138, and the top surface of the first cantilever 138 and the top surface of the first bottom plate 135 smoothly transition , the width of the first cantilever 138 is greater than the inner diameter of the inner flange 61, the width of the first cantilever 138 is smaller than the inner diameter of the bushing 6, and the maximum distance between the end of the first cantilever 138 and the first baffle 136 is smaller than the outer diameter of the bushing 6 The maximum distance betwe...

Embodiment 2

[0032] Such as Figure 4 As shown, the feeding guide rail 134 includes a first channel 141 for accommodating the rolling of the bushing 6, a second channel 142 parallel to the first channel 141, the second channel 142 is connected with the feeding groove 132, and the first channel 141 faces the second channel 142 One end of one end is provided with the second through-hole 143 that accommodates the bushing 6 to move along the axial direction of the bushing 6, and the second channel 142 is provided with the third through-hole 144 coaxial with the second through-hole 143, and the second through-hole 143 One side facing away from the second channel 142 is provided with a first push rod 145 that pushes the bush 6 into the third through hole 144, the radial dimension of the first push rod 145 is smaller than the inner diameter of the bush 6, and the diameter of the first push rod 145 The radial dimension is larger than the inner diameter of the inner flange 61 .

[0033] When the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com