Production method for motor and motor assembly

A manufacturing method and component technology, applied in the field of motor assembly and motor manufacturing, can solve problems affecting motor yield, assembly deviation, difficult positioning of motor components, etc., so as to avoid inaccurate positioning, improve yield, and fix firmly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

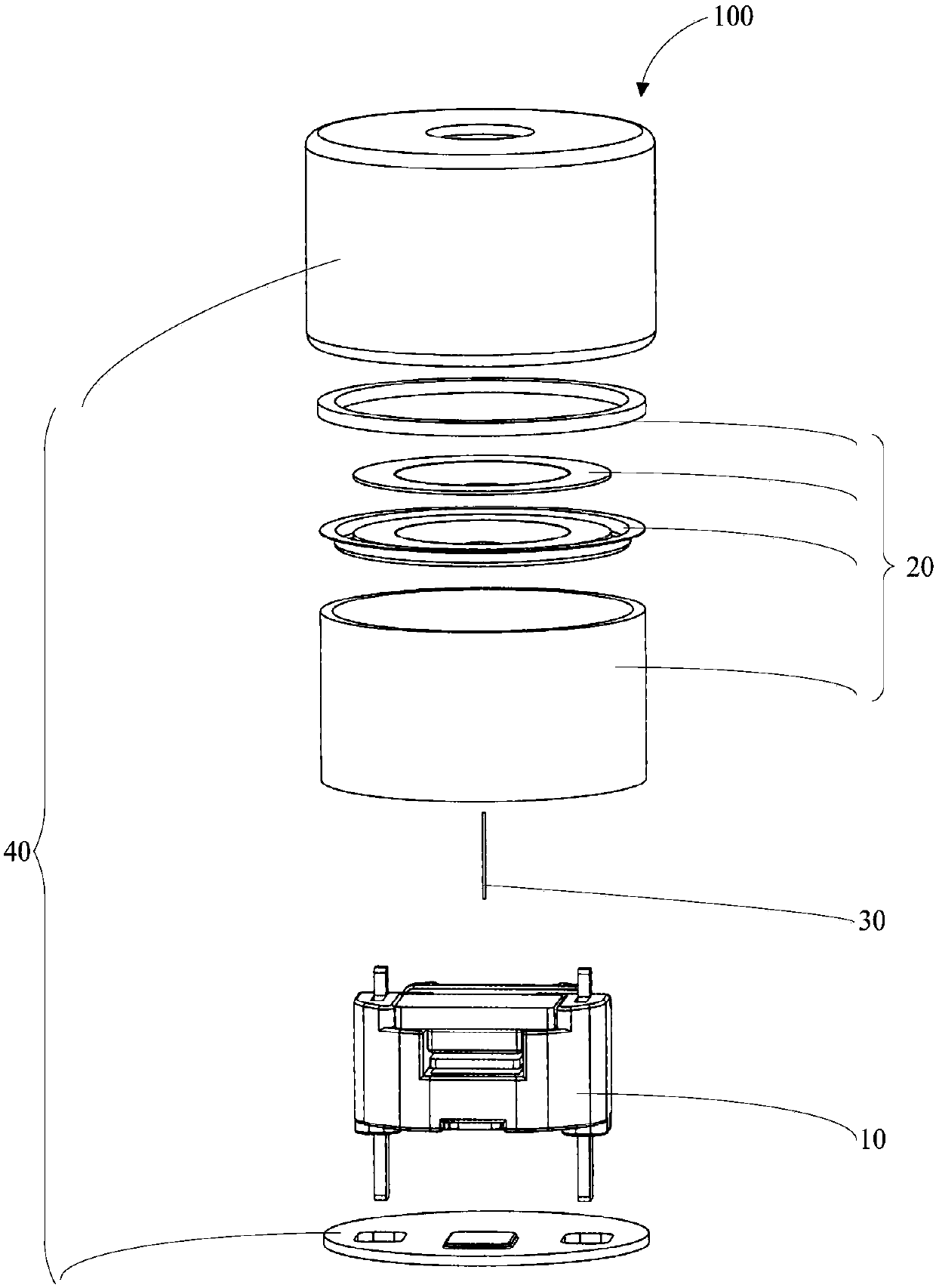

[0057] In order to improve the yield rate of the motor in the manufacturing of the above-mentioned moving iron unit, the present invention provides a method for producing the above-mentioned motor.

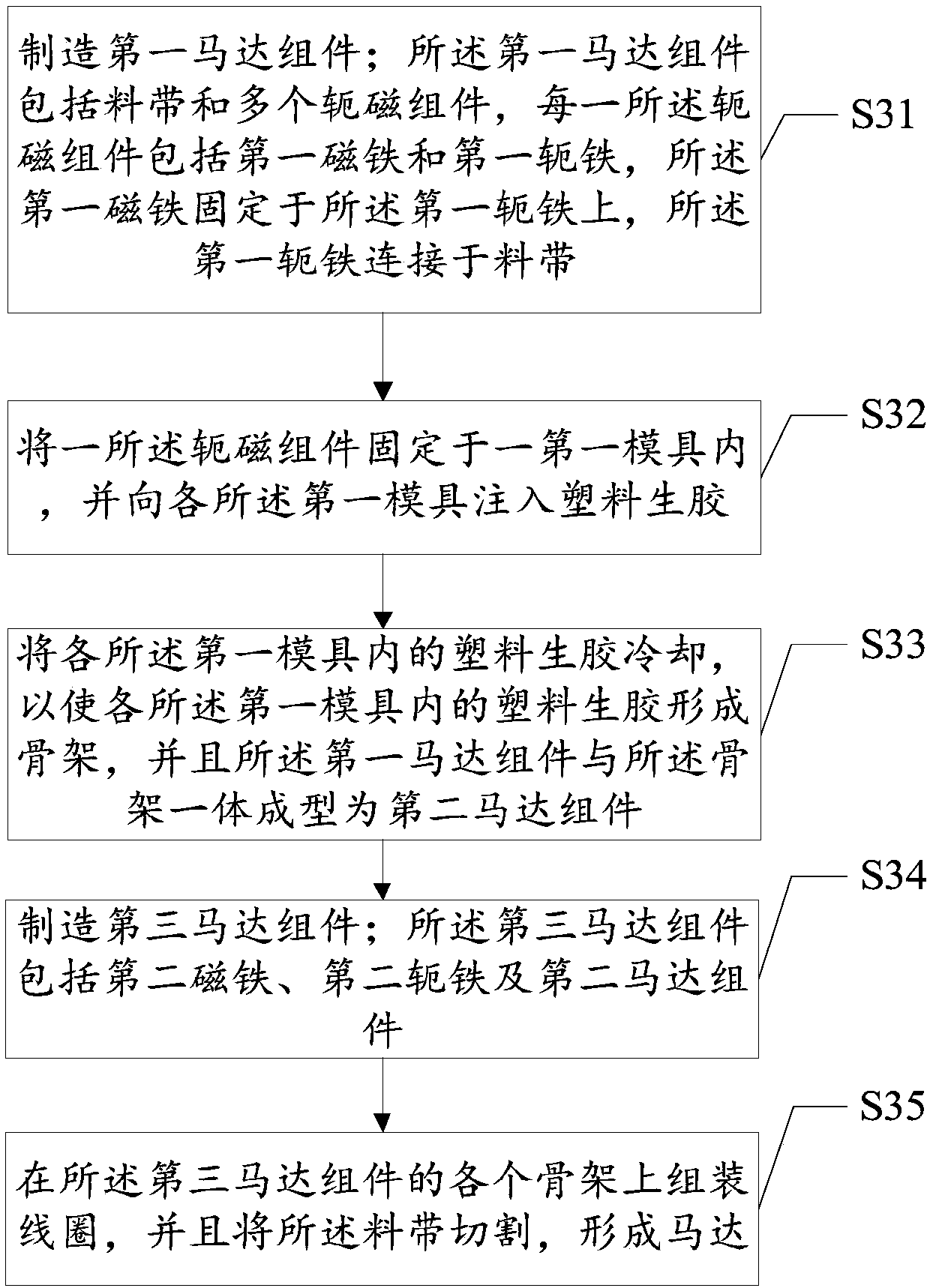

[0058] See image 3 , image 3 It is a schematic flowchart of a method for manufacturing a motor provided by an embodiment of the present invention, including:

[0059] Step S31: Manufacturing a first motor assembly; the first motor assembly includes a material tape and a plurality of yoke magnetic assemblies (not labeled), each of the yoke magnetic assemblies includes a first magnet and a first yoke, the first The magnet is fixed on the first yoke, and the first yoke is connected to the material belt;

[0060] Specifically, the first motor assembly such as Figure 4 Shown. The manufacturing process of the first motor assembly includes:

[0061] First fix the strip-shaped blanks on the assembly line by clamps. The strip-shaped blanks include a plurality of blank units. Each of the blank ...

Embodiment 2

[0086] See Figure 7 , The motor assembly 50 includes a first magnet 51, a first yoke 52, a frame 53, a lead wire outlet 54 and a material belt 55.

[0087] The number of the frame 53, the first yoke 53 and the first magnet 52 are multiple, and one of the first yoke 53 and one of the first magnets 51 are fixed, and the first yoke 52 is fixed to one of the first magnets 51. The frame 53 is fixed, and each first yoke 53 is connected to the material belt 55.

[0088] The material belt 55 is provided with a first positioning hole 551 and a second positioning hole 552. See Figure 8 The above-mentioned first magnet 51 has a rectangular parallelepiped structure, but may also be a cube structure or other three-dimensional structure that satisfies the fixation of the first magnet 51 to the first yoke 52.

[0089] See Picture 9 The above-mentioned first yoke 52 includes a yoke body 521, a first yoke arm 522, and a second yoke arm 523. The first yoke 52 has a U-shaped structure, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com