Amphibious ship with wheels capable of being automatically contracted

An automatic shrinking, wheel technology, applied in amphibious vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of small driving torque, unsafe, time-consuming and labor-intensive, and achieve fast and effective turning, ensure safety, and save the mechanical structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with specific embodiments.

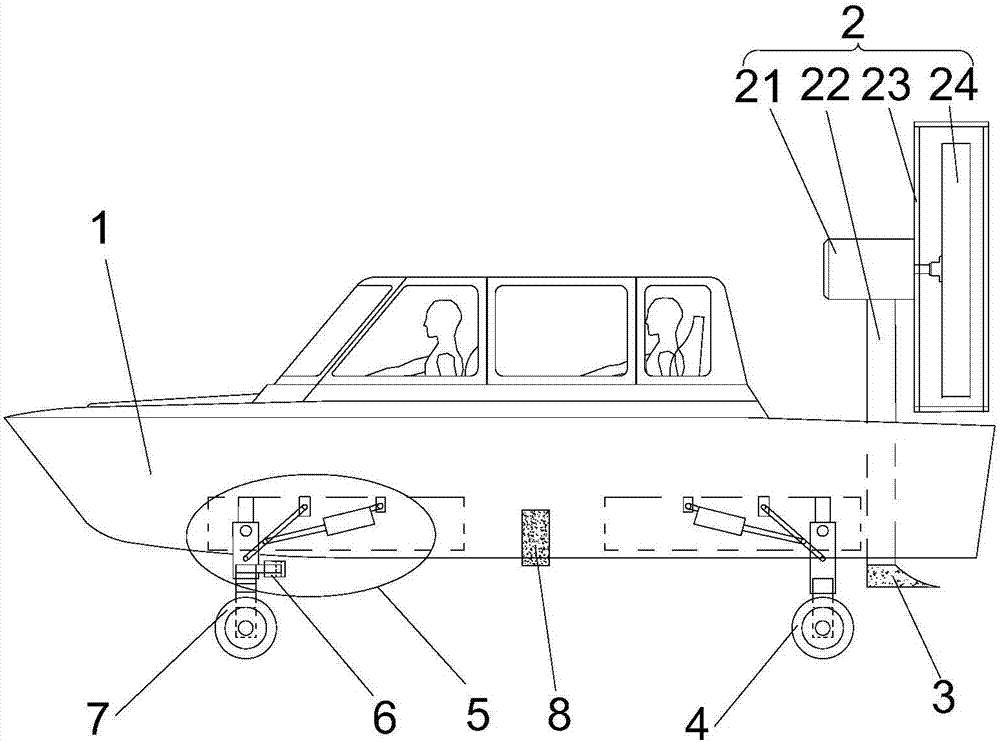

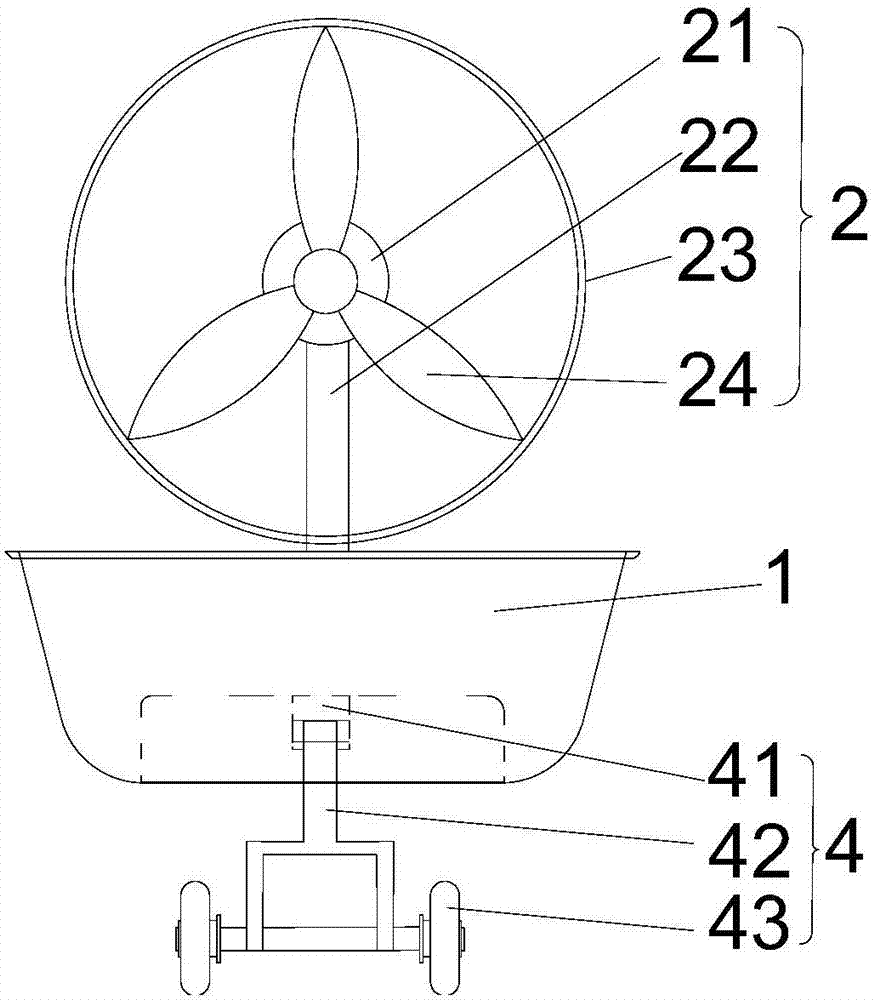

[0025] refer to Figure 1-5 , an amphibious boat with automatic shrinking wheels, comprising a hull 1, a power unit 2 and a steering rudder 3, the tail of the hull 1 is provided with a power unit 2, and the power unit 2 includes a motor 21, a guide shaft 22, a guard Cover 23 and propeller 24, one end of the guide shaft 22 is fixedly connected to the bottom end of the motor 21, and the other end of the guide shaft 22 passes through the hull 1 and is connected to the guide rudder 3, and one side of the motor 21 is fixedly connected to the propeller 24, the outer side of the propeller 24 is provided with a shield 23;

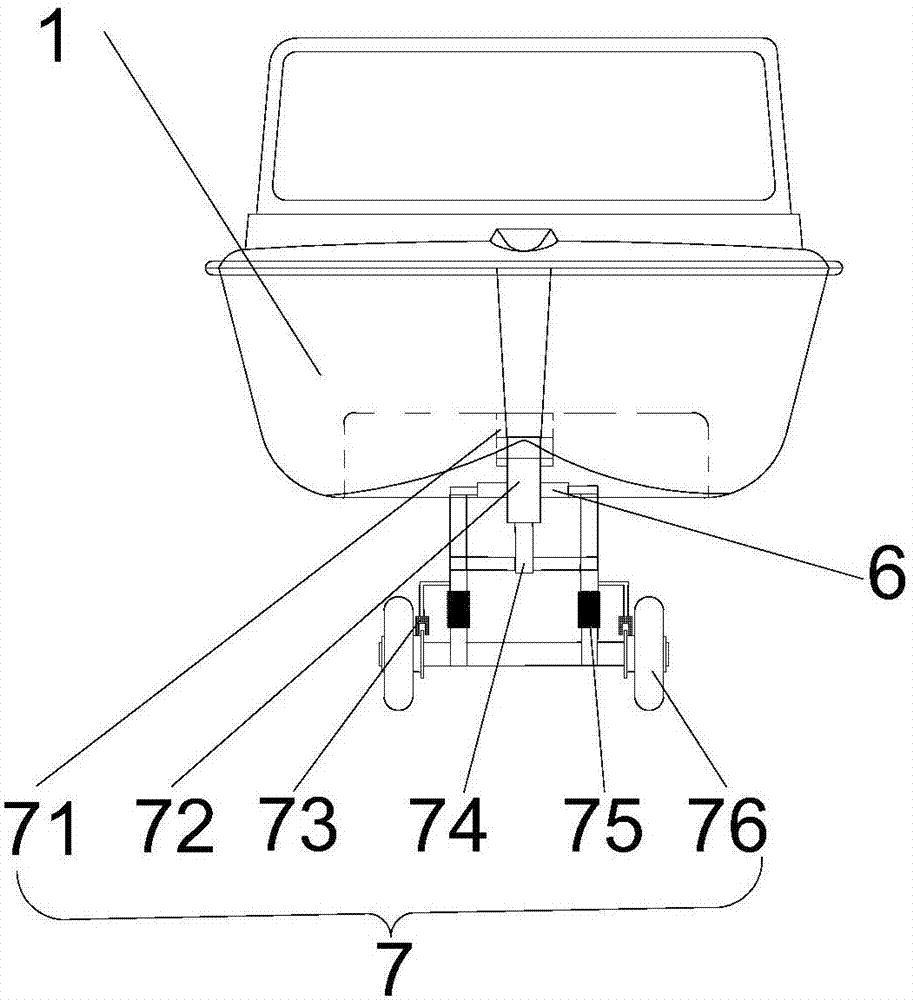

[0026] The bottom end of the middle part of the hull 1 is provided with a liquid level sensor 8, the bottom end of the head of the hull 1 is provided with a head groove, and a front bearing seat 71 is fixed on one side of the upper end surface of the head groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com