Axle box structure with anti-skid and monitoring functions and used for railway vehicle

A rail vehicle and axle box technology, which is applied in the field of the axle box structure of urban rail subway vehicle bogies, can solve the problems that cannot meet the technical requirements, signal equipment is not compatible with speed measuring gears, etc., and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

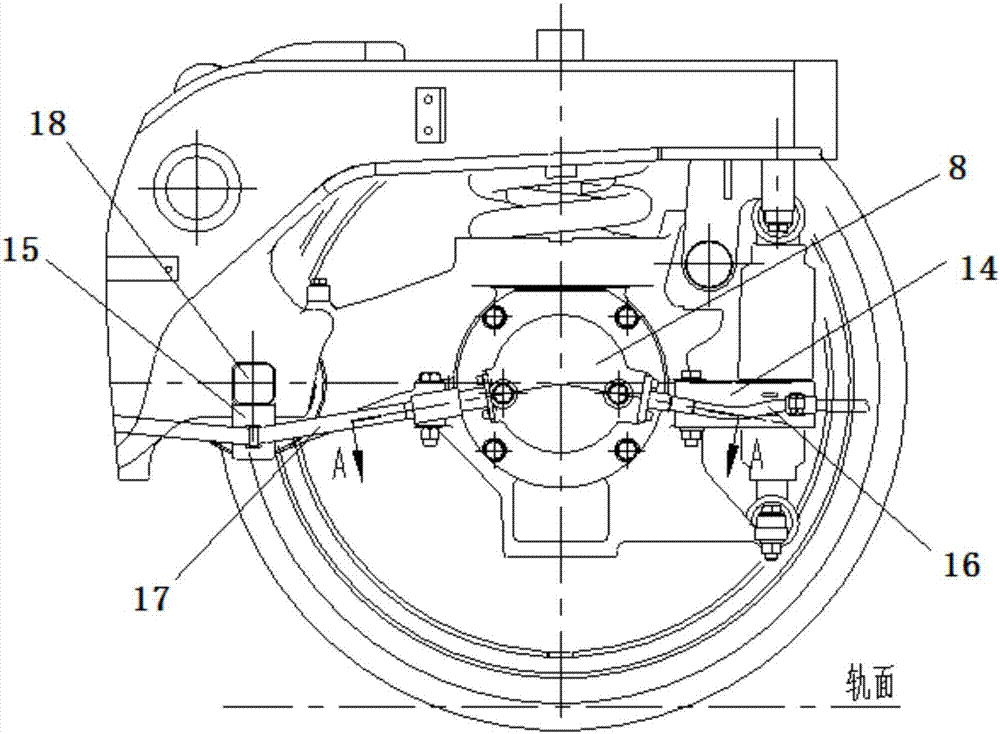

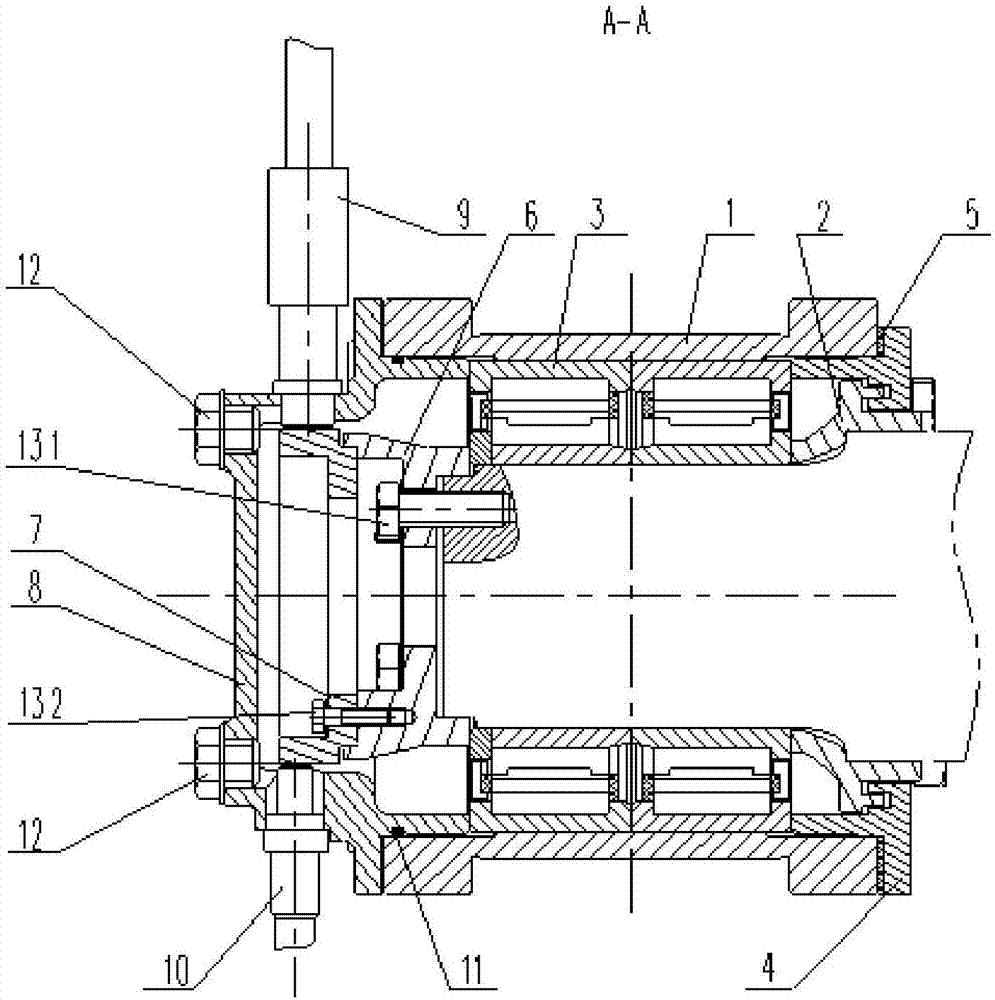

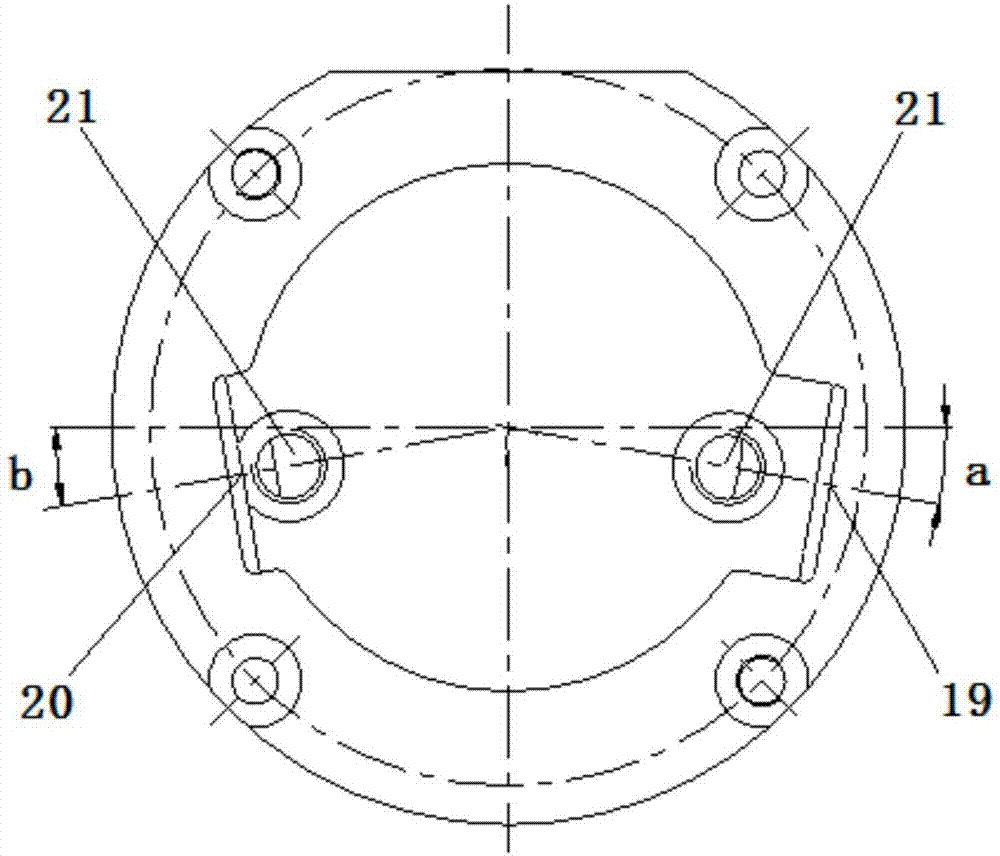

[0020] Such as figure 1 , figure 2 , image 3 As shown, the rail vehicle has an axle box structure with both anti-skid and monitoring functions, including an axle box body 1 that is sleeved on the end of the wheel axle through a bearing, and an axle box gland 6 that is fixed on the outside of the wheel axle end through a first fastening screw 131. , and the gear 7 fixed to the outer end of the axle box gland by the second fastening screw 132, in this implementation, the gap between the tooth tip of the gear and the signal sensor and the speed sensor is 0.9 ± 0.5mm. The gear has 100 teeth and a modulus of 1.5. The outer end of the axle box body 1 is fixed with an axle box cover 8, and the axle box cover 8 is provided with a speed sensor installation interface 19 far away from the center of the bogie and a signal sensor installation interface 20 close to the center of the bogie. Viewed from the axle end, the speed sensor installation interface The central line of 19 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com