Damping type material barrel capable of achieving tool hanging

A material barrel and tool technology, applied in the direction of preventing mechanical damage to containers, containers, container handles, etc., can solve the problems of short service life of the material barrel, inability to achieve shock absorption, inconvenient tool search, etc., to prolong the service life and facilitate The effect of hooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

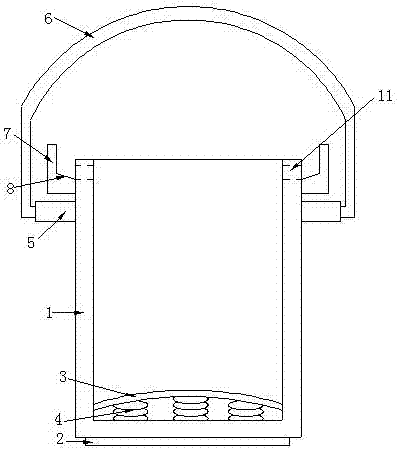

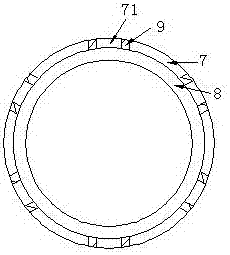

[0016] Such as figure 1 , figure 2 As shown, this specific embodiment adopts the following technical solutions: it includes a cylinder body 1, a shock-absorbing anti-skid pad 2, an inner bottom plate 3, a shock-absorbing spring 4, a rotating sleeve 5, a handle 6, an outer frame 7, and an inner plate 8 , anti-slip mat 9; the bottom of the cylinder 1 is equipped with a shock-absorbing anti-skid mat 2, and the inner bottom of the cylinder 1 is equipped with se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com