Embedded ultrathin friction course for upper layer of pavement and construction method thereof

An embedded and wear-resistant layer technology, which is applied in the direction of roads, roads, and cohesive pavements paved on site, can solve the problems of poor bonding between layers, reflection cracks, and insufficient surface anti-skid, etc. , good anti-skid performance, reduce the effect of water mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

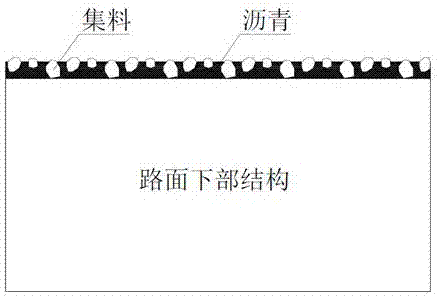

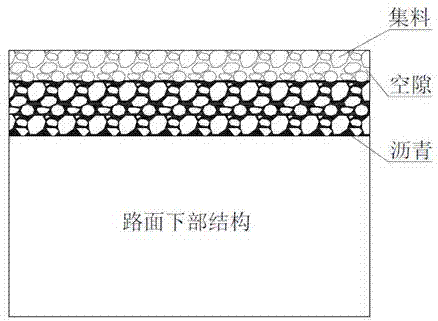

[0022] In order to solve the shortcomings of the existing thin-layer asphalt concrete as the upper layer of the road, the present invention proposes an embedded ultra-thin wear layer structure for the first time, which is a gravel seal layer using high-viscosity asphalt in the lower layer and large-void asphalt concrete in the upper layer. The high-viscosity asphalt in the crushed stone seal is partially embedded in the voids of the large-void asphalt concrete, thereby forming a related structure in which the crushed stone seal and the large-void asphalt concrete are embedded and interwoven.

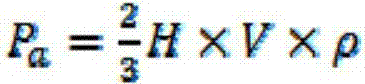

[0023] The upper structure adopts large-void asphalt concrete with a porosity of 15% to 30%, and the high-viscosity asphalt in the gravel seal can be filled in the voids in high-temperature seasons to prevent oil flooding of the structure in high-temperature season...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com