Industrial solid waste geopolymer material for building 3D printing and preparation method thereof

A technology of industrial solid waste and 3D printing, which is applied in the field of construction 3D printing materials, can solve problems such as the inability to freely control the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

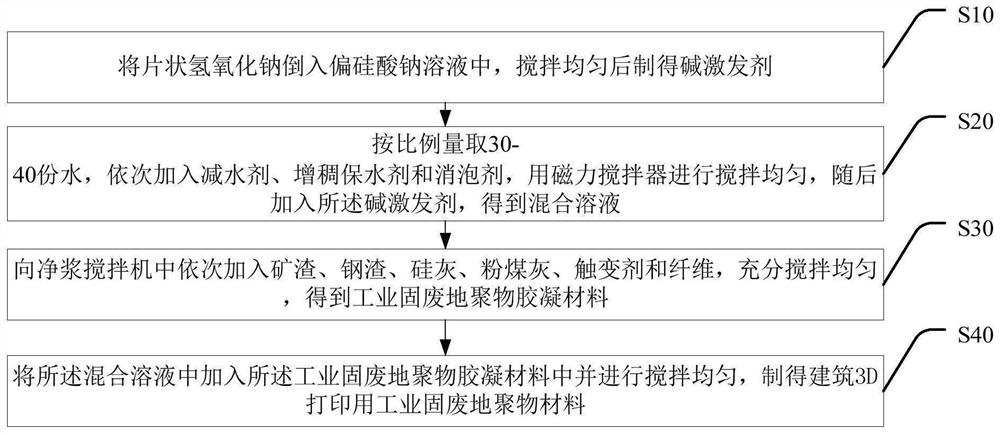

[0037] In some embodiments, there is also provided a method for preparing industrial solid waste geopolymer materials for building 3D printing as described above, such as figure 1 As shown, it includes the steps:

[0038] S10. Pour the flake sodium hydroxide into the sodium metasilicate solution, and stir evenly to prepare the alkali activator;

[0039] S20. Measure 30-40 parts of water in proportion, add water reducing agent, thickening water retaining agent and defoamer in sequence, stir evenly with a magnetic stirrer, and then add the alkali activator to obtain a mixed solution;

[0040] S30, sequentially add slag, steel slag, silica fume, fly ash, thixotropic agent and fiber into the slurry mixer, fully stir evenly, and obtain industrial solid waste geopolymer cementitious material;

[0041] S40, adding the mixed solution into the industrial solid waste geopolymer gelling material and stirring evenly to prepare an industrial solid waste geopolymer material for building 3D...

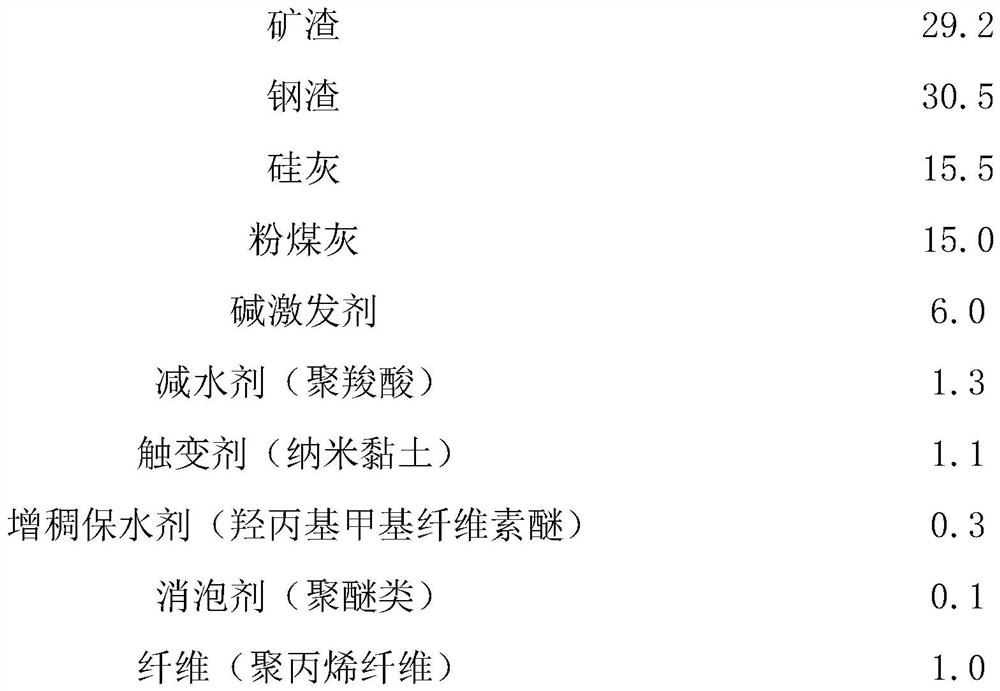

Embodiment 1

[0045] Prepare the following substances in parts by weight:

[0046]

[0047] Preparation method: Weigh the raw materials according to the formula, slowly pour 0.6 parts of flaky sodium hydroxide into 5.4 parts of sodium metasilicate solution, and keep stirring to dissolve the flaky sodium hydroxide. The stimulator is on standby.

[0048] Sequentially add weighed slag, steel slag, silica fume, fly ash, thixotropic agent and fiber into the slurry mixer, and fully stir evenly to obtain powdery industrial solid waste geopolymer cementitious material.

[0049] Take 33 parts of water, add water reducing agent, thickening water retaining agent and defoamer in sequence, stir evenly with a magnetic stirrer, and then add the compounded alkali activator to obtain a mixed solution.

[0050] Slowly add the stirred mixed solution into the powdery industrial solid waste geopolymer gelling material and stir evenly for 3 minutes to prepare printing paste.

[0051] Use computer drawing so...

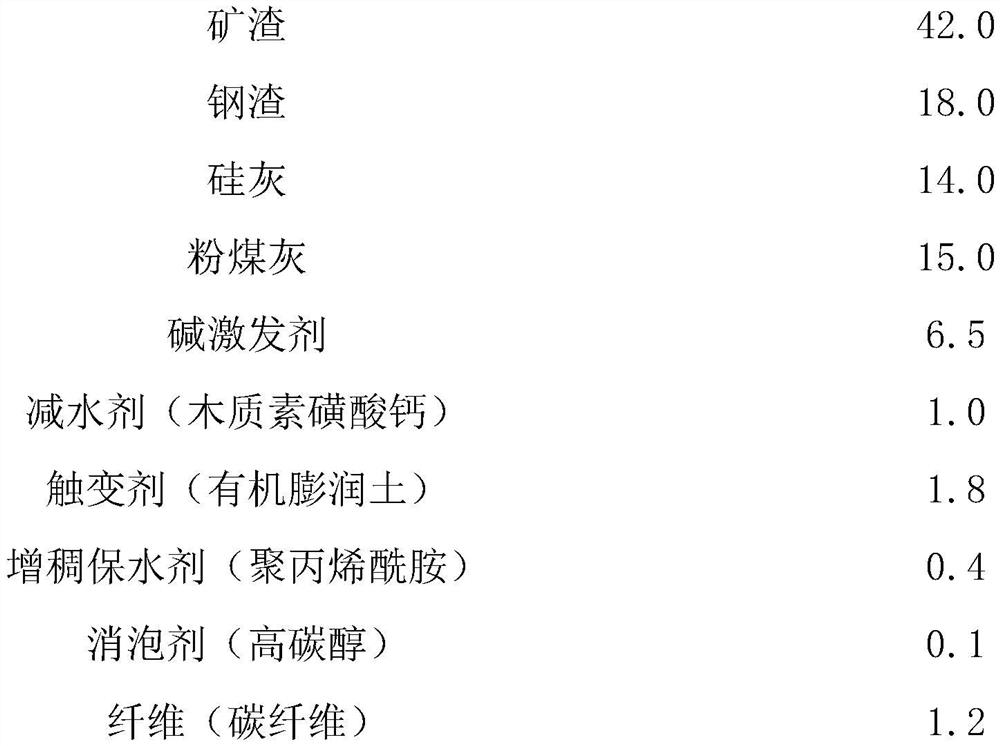

Embodiment 2

[0056] Prepare the following materials in parts by weight:

[0057]

[0058] Preparation method: Weigh the raw materials according to the formula, slowly pour 1.3 parts of flake sodium hydroxide into 5.2 parts of sodium metasilicate solution, and keep stirring to dissolve the flake sodium hydroxide. The stimulator is on standby.

[0059] Sequentially add weighed slag, steel slag, silica fume, fly ash, thixotropic agent and fiber into the slurry mixer, and fully stir evenly to obtain powdery industrial solid waste geopolymer cementitious material.

[0060] Take 34 parts of water, add water reducing agent, thickening water retaining agent and defoamer in sequence, stir evenly with a magnetic stirrer, and then add the compounded alkali activator to obtain a mixed solution.

[0061] Slowly add the stirred mixed solution into the powdery industrial solid waste geopolymer gelling material and stir evenly for 3 minutes to prepare printing paste.

[0062] Use computer drawing sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com