Quick Overhaul Method for Corroded Plane Gate of Hydropower Station

A technology for plane gates and hydropower stations, which can be used in water conservancy projects, marine engineering, construction, etc., and can solve the problems of inconvenient transportation of plane gates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

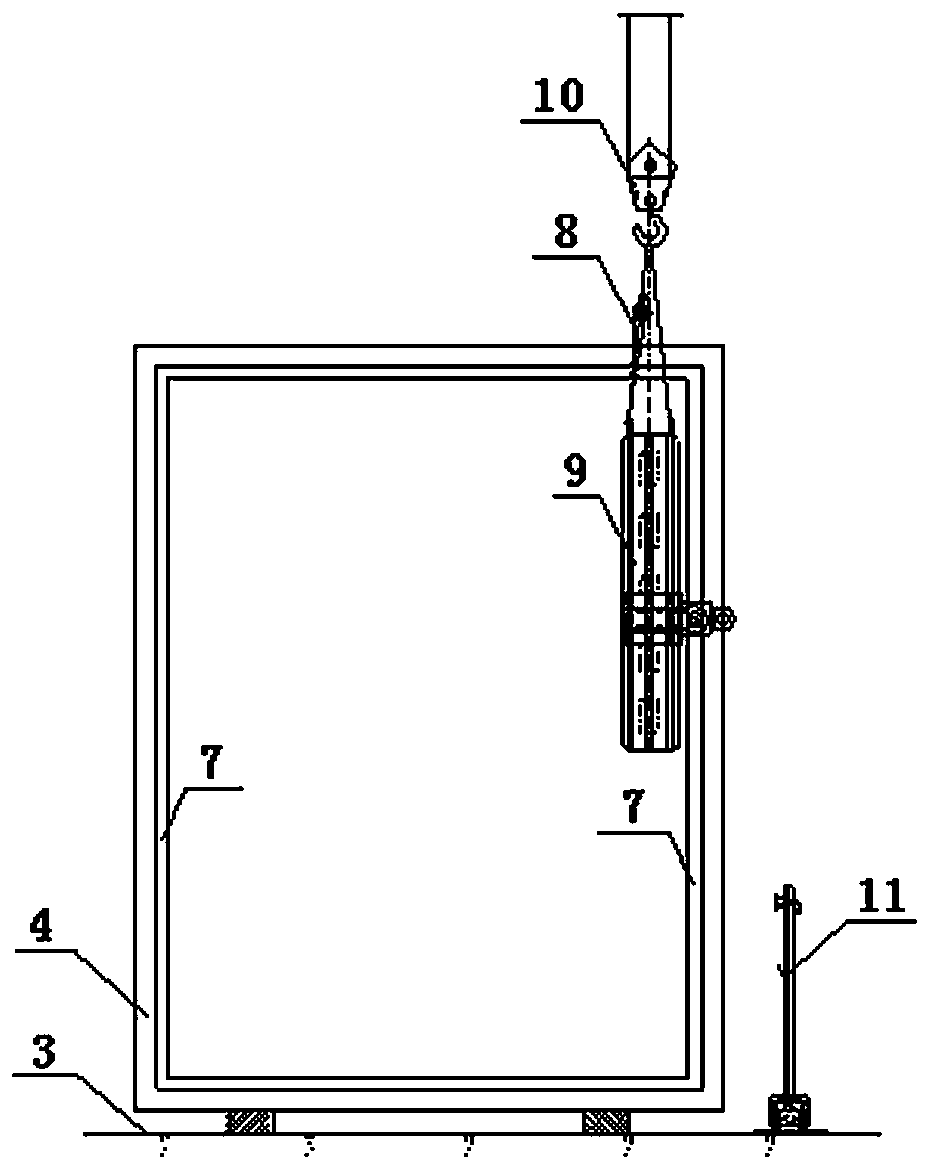

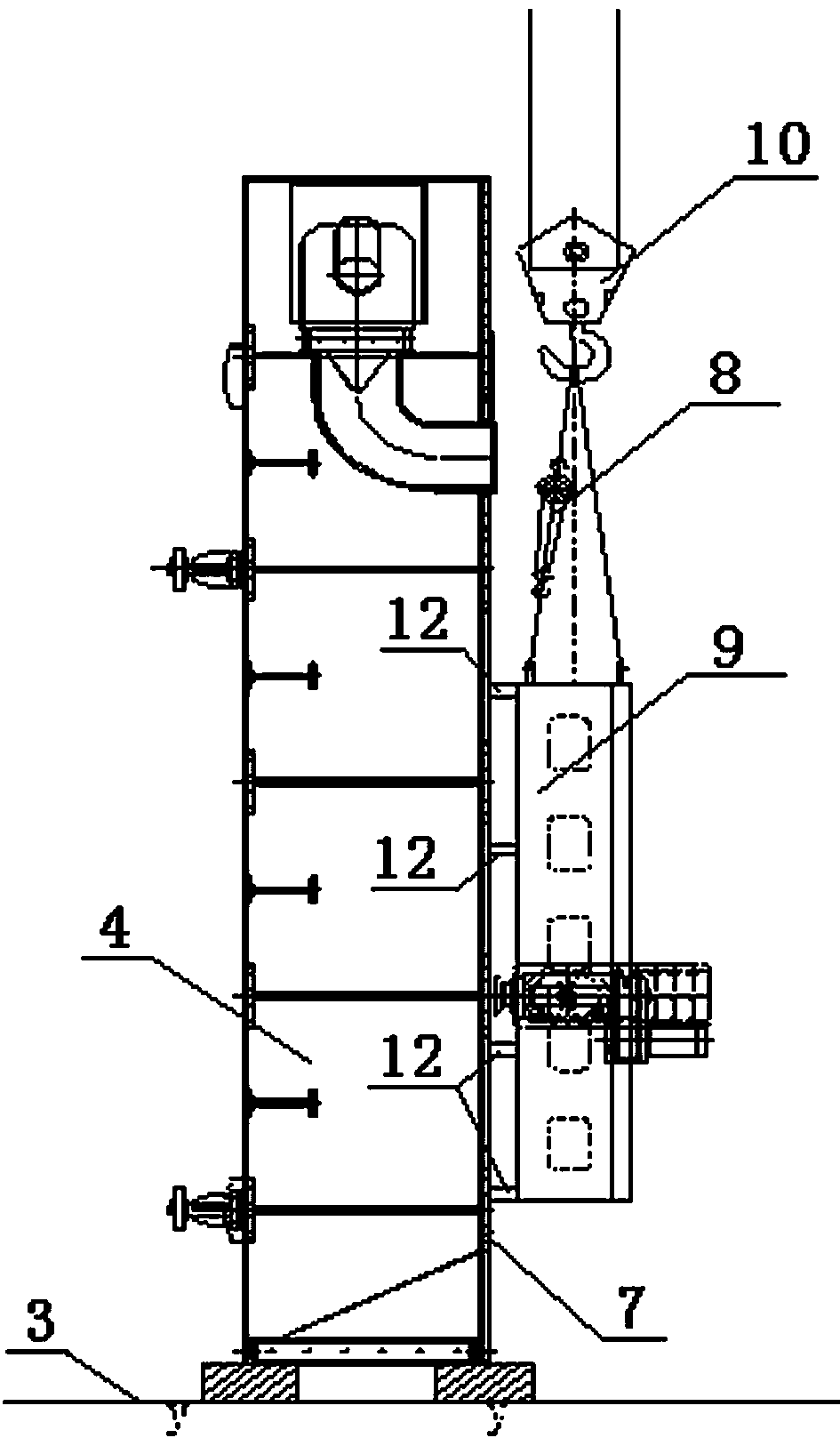

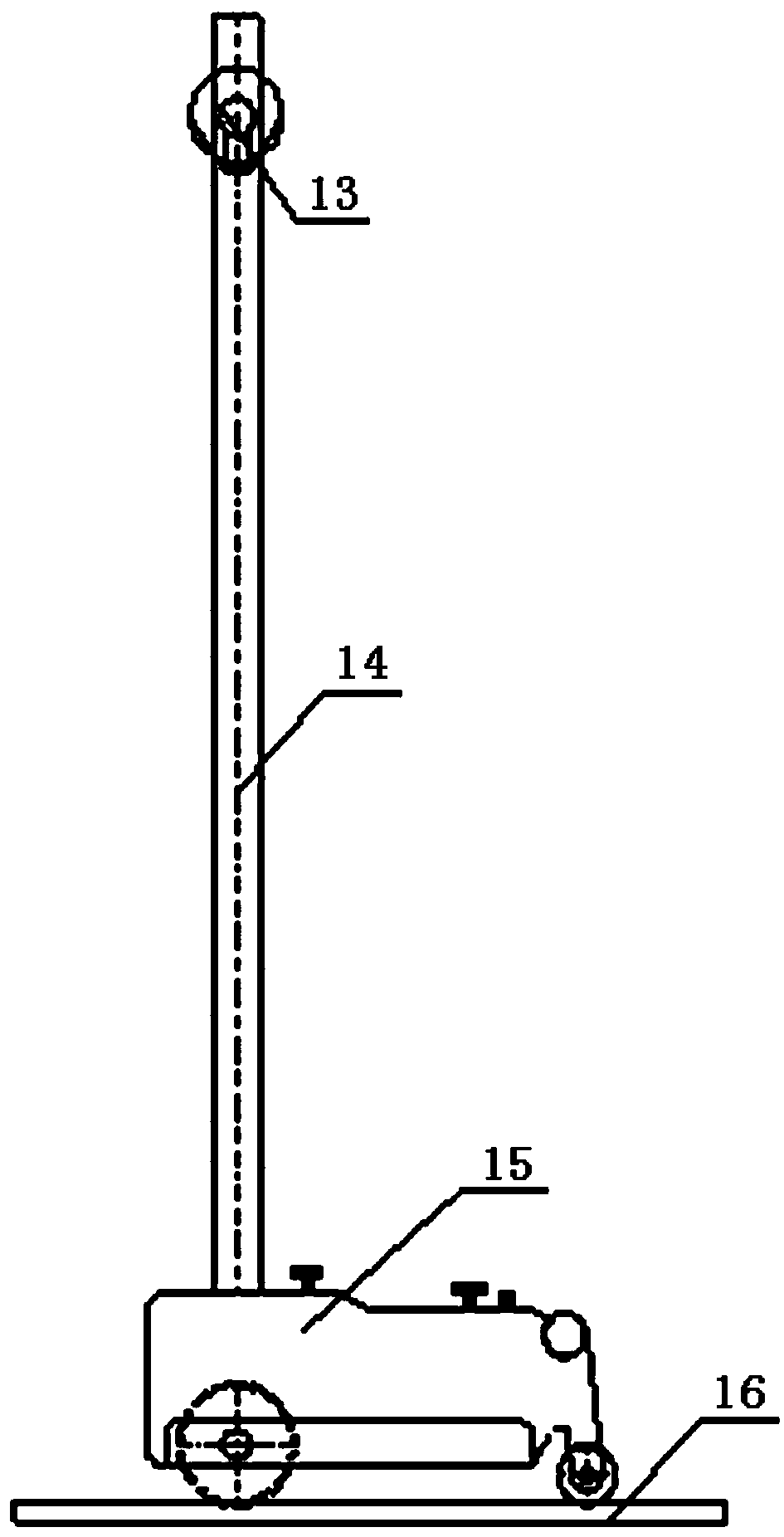

[0018] Such as figure 1 , figure 2 , image 3 As shown, the rapid maintenance method for the corroded flat gate of the hydropower station in this embodiment includes the following steps:

[0019] 1. Install a curved steel pipe frame movable workshop track at the 5th hole of the gate slot to be overhauled;

[0020] 2. Lock the gate slot opening:

[0021] Use the chain hoist 8 and lifting equipment 10 of the gate to lift the corroded flat gate 4 to be repaired to the opening of the gate slot 5, and use the gate lock beam 2 to lock the gate leaf to the opening of the gate slot;

[0022] 3. Dredging:

[0023] Use a high-pressure water gun to wash the sludge in the gate leaf at the gate slot orifice to clean the gate thoroughly and return the sludge to the water to avoid secondary cleaning;

[0024] 4. Removal of accessories:

[0025] Use an oxygen-acetylene gas cutting gun to cut off the attachment fasteners. When cutting, pay attention to protect the gate body to prevent damage to important...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com