Internal and external support structure of building foundation pit and construction method

A technology of support structure and construction method, applied in basic structure engineering, construction, excavation, etc., can solve the problems of high connection requirements of support components, complex internal support structure type, complicated construction, etc., to avoid adverse effects, save raw materials, reduce The effect of the amount of anchor rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments will be described in detail below in conjunction with the accompanying drawings.

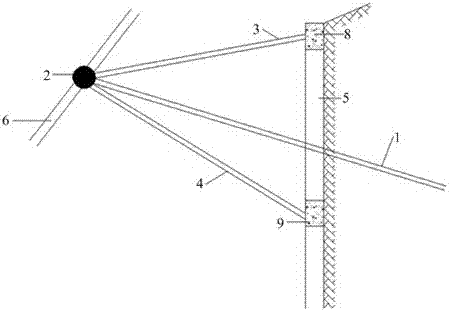

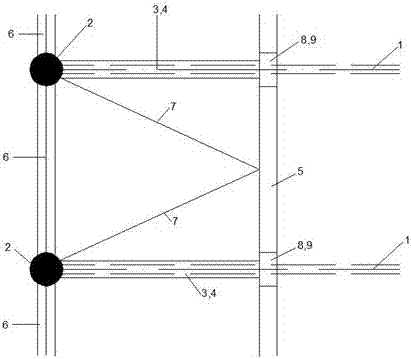

[0028] See attached figure 1 And attached figure 2 , an internal and external support structure of a building foundation pit, comprising an anchor rod / cable 1, a spherical steering support 2, an upper pressing rod 3, a lower pressing rod 4, a supporting pile 5, an inner supporting structure 6 and an inner and outer supporting connecting rod 7, The anchor rod / cable 1 is a rock-soil anchor rod / cable with a large dip angle of 30°~60°. One end of the anchor rod / cable 1 is anchored in a stable rock-soil body, and the other end goes deep into the foundation pit and connects with the spherical steering support 2 The support pile 5 is provided with a crown beam 8 and a waist beam 9, one end of the upper pressure rod 3 is connected with the spherical steering support 2, and the other end is connected with the crown of the support pile 5. The beam 8 is connected; one end of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com