Returnable used protecting handrail

A technology for protective railings and crossbars, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of difficulty in filling up the protective railings in time, difficult to achieve the expected safety protection goals, and falling from heights, etc. The effect of standardized management level, quick installation and dismantling, and saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

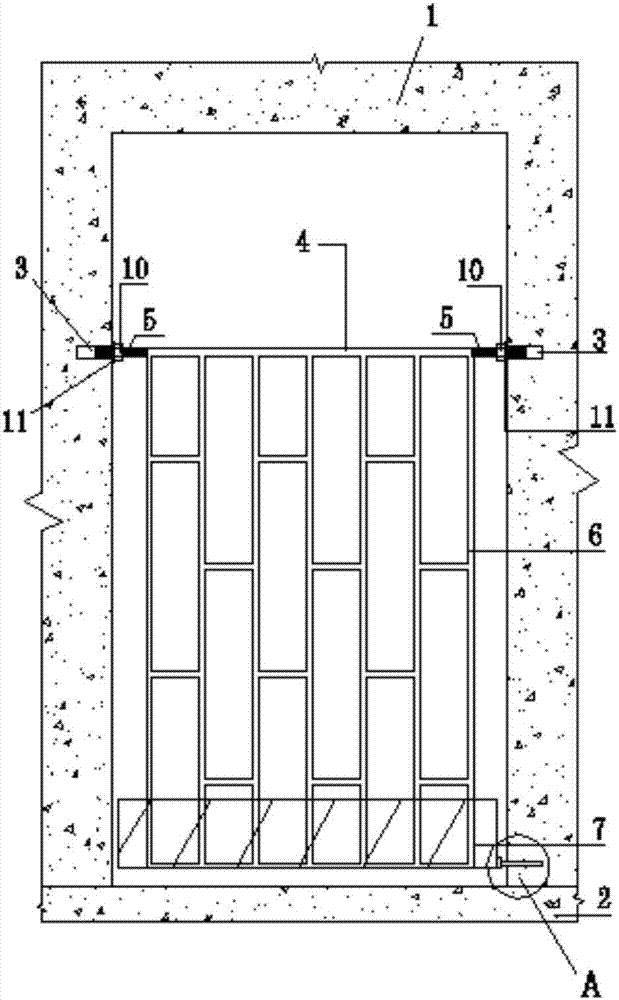

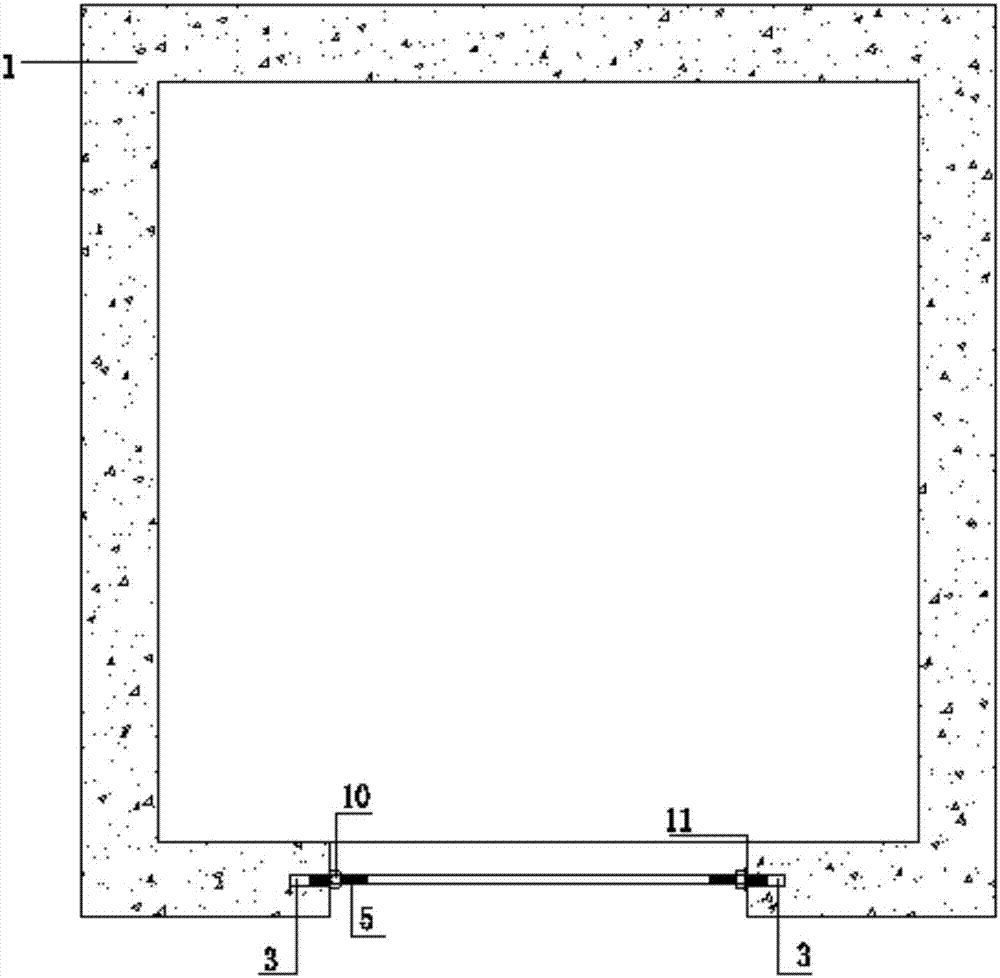

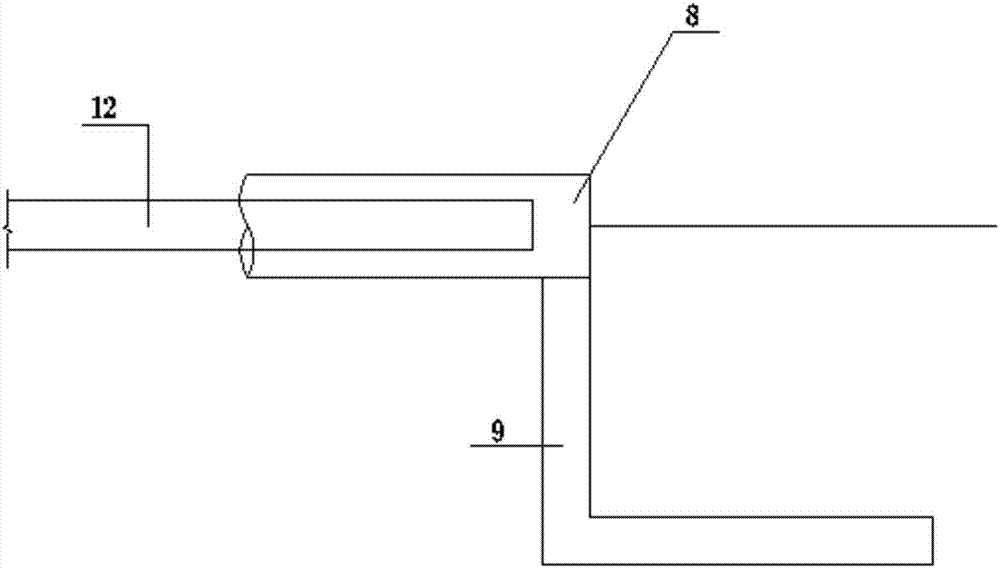

[0018] Such as Figure 1-Figure 3 As shown, a protective railing that can be turned over is used. The protective vertical bar 6 is welded between the protective upper rail 4 and the protective lower rail 12. Both ends of the protective upper rail 4 are connected to be fixed on the concrete wall 1. The screw rod 5 in the hole 3 is fixed by the nut 10, the opening of the sleeve 8 is sleeved on the protective lower cross bar 12, the non-open end of the sleeve 8 is welded to the steel corner bracket 9, and the steel corner bracket 9 The end is connected with the door opening limit, and the foot guard 7 is arranged on the bottom of the protective railing.

[0019] The length of the screw rod 5 extending into the reserved hole 3 is 50mm.

[0020] The protective vertical bar 6 adopts Made of steel.

[0021] Described foot guard 7 is the wooden plate that is coated with red and white alternate colors of wide 200mm, and setting position is apart from floor 250mm place, and its lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com