Power-supply-free automatic lubricating and oil supplying device for elevator head sheave sliding bearing

A sliding bearing and automatic lubrication technology, which is applied in the direction of lubricating oil control valve, engine lubrication, lubricating pump, etc., can solve the problems that the sky wheel device cannot be upgraded, it is difficult to promote, and the labor intensity of personnel is high, so as to save labor maintenance costs And labor intensity, reduce equipment costs and maintenance costs, reduce the effect of manual refueling times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples:

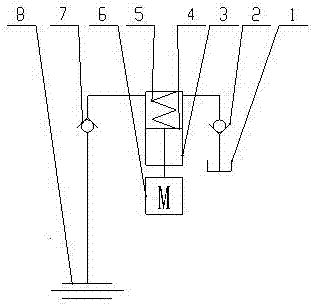

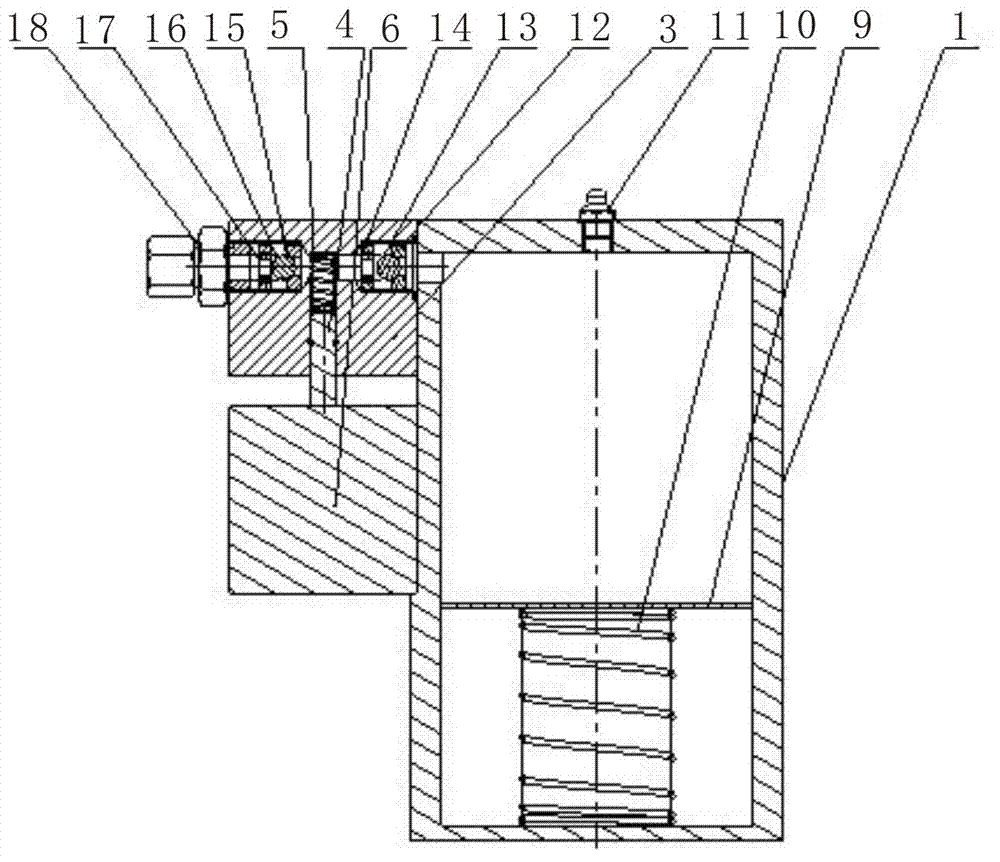

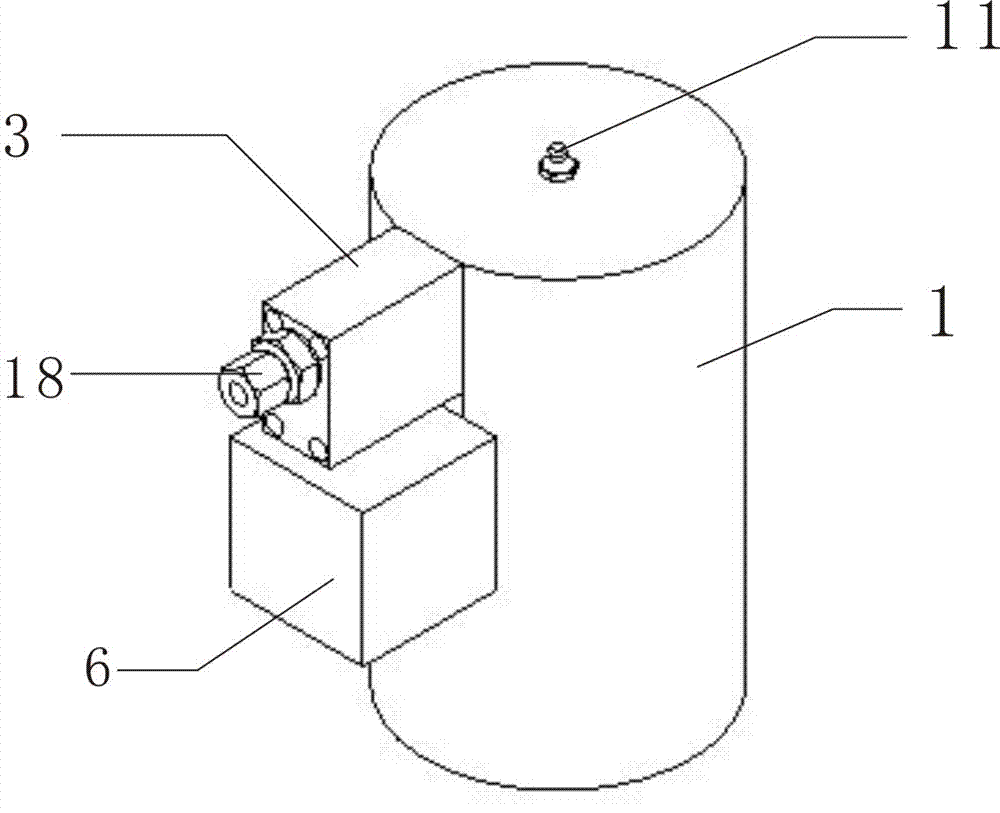

[0028] Combined with the automatic lubricating oil supply device without power supply for the sliding bearing of the sky wheel of the hoist shown in the attached drawing, the oil supply device is installed at the rim of the sky wheel, and each half copper tile of the traveling wheel is equipped with a set.

[0029] The oil supply device includes an oil barrel 1, the oil barrel 1 is connected with the piston cylinder 3 through the oil suction check valve 2, the piston cylinder 3 is provided with a return spring 5 and a piston rod 4, and the lower end of the piston rod 4 is provided with a weight 6, The oil outlet of the piston cylinder 3 is provided with an oil outlet check valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com