Integrated liquid treatment device

A liquid treatment, integrated technology, applied in filtration treatment, special treatment targets, oxidized water/sewage treatment, etc., can solve the problems of needing staff on duty, poor oil removal effect, low treatment efficiency, etc., to improve the oil-water separation effect. , easy maintenance, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

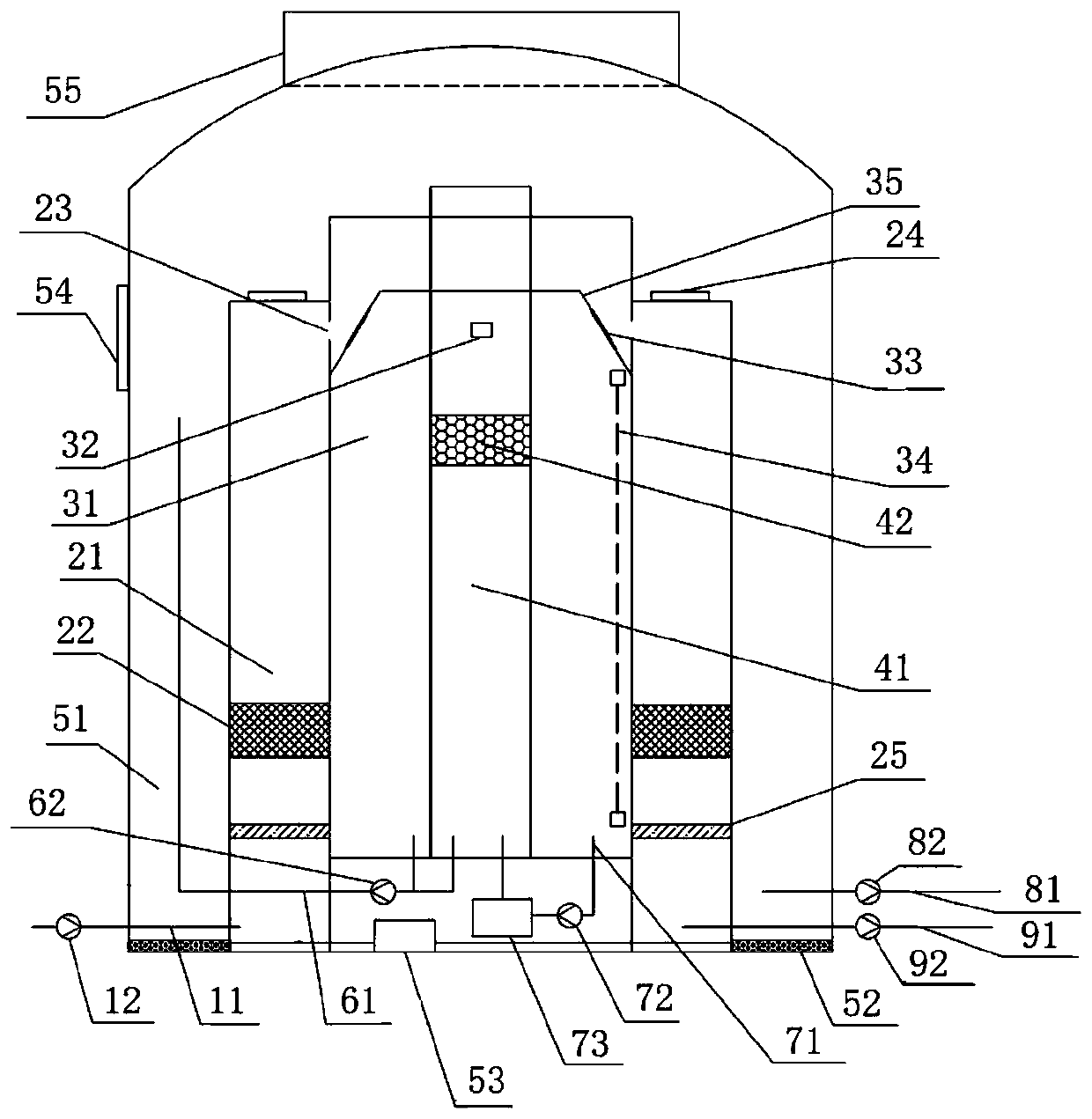

[0040] figure 1 Schematically presents a simplified structural diagram of an integrated liquid treatment device in an embodiment of the present invention, as shown in figure 1 As shown, the integrated liquid handling device includes:

[0041] Liquid inlet pipeline 11 and pump 12, liquid outlet pipeline 81 and pump 82;

[0042] A plurality of cavities surrounding and mutually isolated from the inside to the outside, the multiple cavities include a first cavity 21, a second cavity 31 and a third cavity 41; the liquid inlet pipe 11 communicates with the first cavity 21, so The outlet pipe 91 communicates with the second chamber 31;

[0043] filter media 22, 25, the filter media are arranged in the first cavity 21, and are downstream of the liquid inlet pipe 11 of the liquid flow path;

[0044] A baffle 35, the baffle 35 is obliquely arranged on the upper part of the second chamber 31, and has a through hole 33, the baffle 35 at the lower part of the through hole 33 and the side ...

Embodiment 2

[0056] The application example of the integrated liquid treatment device according to the embodiment of the present invention is, for example, oil-water separation in the treatment of cutting fluid, release agent, and degreasing bath liquid.

[0057] In this application example, if figure 1 As shown, the four cavities surrounding and isolated from the inside to the outside are concentrically distributed, which are the third cavity 41, the second cavity 31, the first cavity 21 and the fourth cavity 51; the liquid inlet pipe 11 and the The bottom in the first chamber 21 is connected, and the liquid outlet pipe 81 is directly connected with the fourth chamber and indirectly connected with the second chamber 31;

[0058] In the first chamber 21, the secondary filter media 22, 25 are arranged in the annular first chamber 21, and are successively (coarse filtration first, then fine filtration) downstream of the liquid inlet pipeline 11 of the liquid flow path; the first chamber The...

Embodiment 3

[0064] The application example of the integrated liquid treatment device according to the embodiment of the present invention is, for example, oil-water separation in the treatment of cutting fluid, release agent, and degreasing bath liquid. The difference with embodiment 2 is:

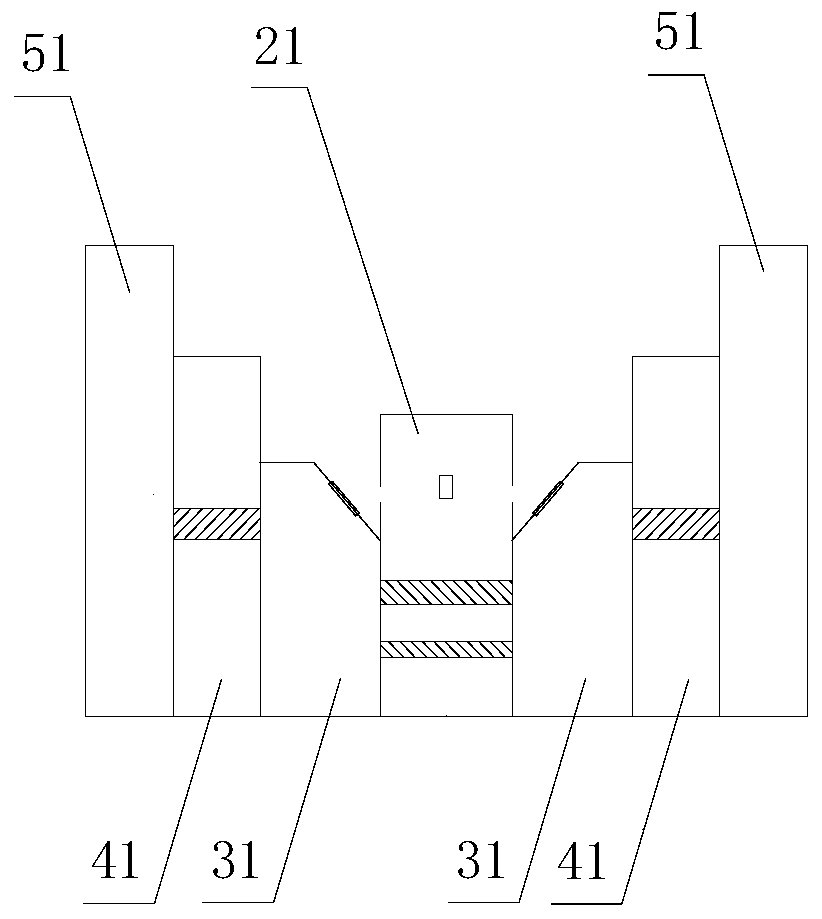

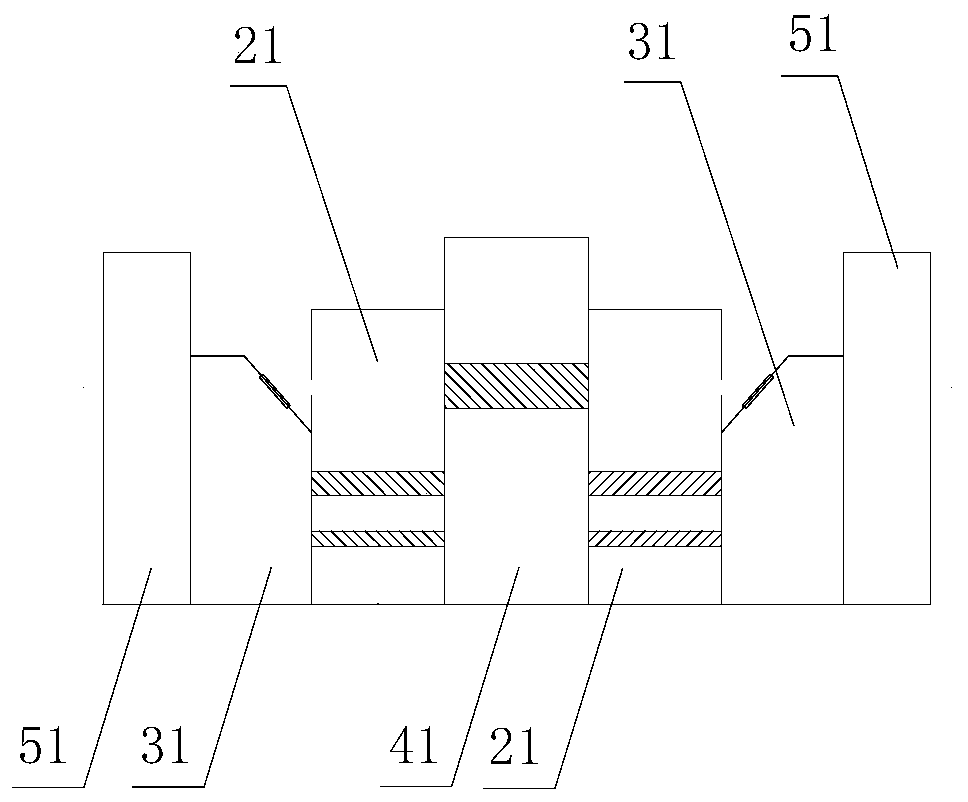

[0065] Such as figure 2 As shown, the four cavities surrounding and isolated from each other and concentrically distributed from the inside to the outside are the first cavity 21 , the second cavity 31 , the third cavity 41 and the fourth cavity 51 in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com