Middle cooking fume sucking and removing hot pot boiler

A boiler and oil fume technology, which is applied in the field of fire boilers, can solve the problems of low position of oil suction fume, poor effect of oil fume extraction device, large turbulent flow, etc., and achieve the effect of reducing oil fume emission, compact structure and small turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

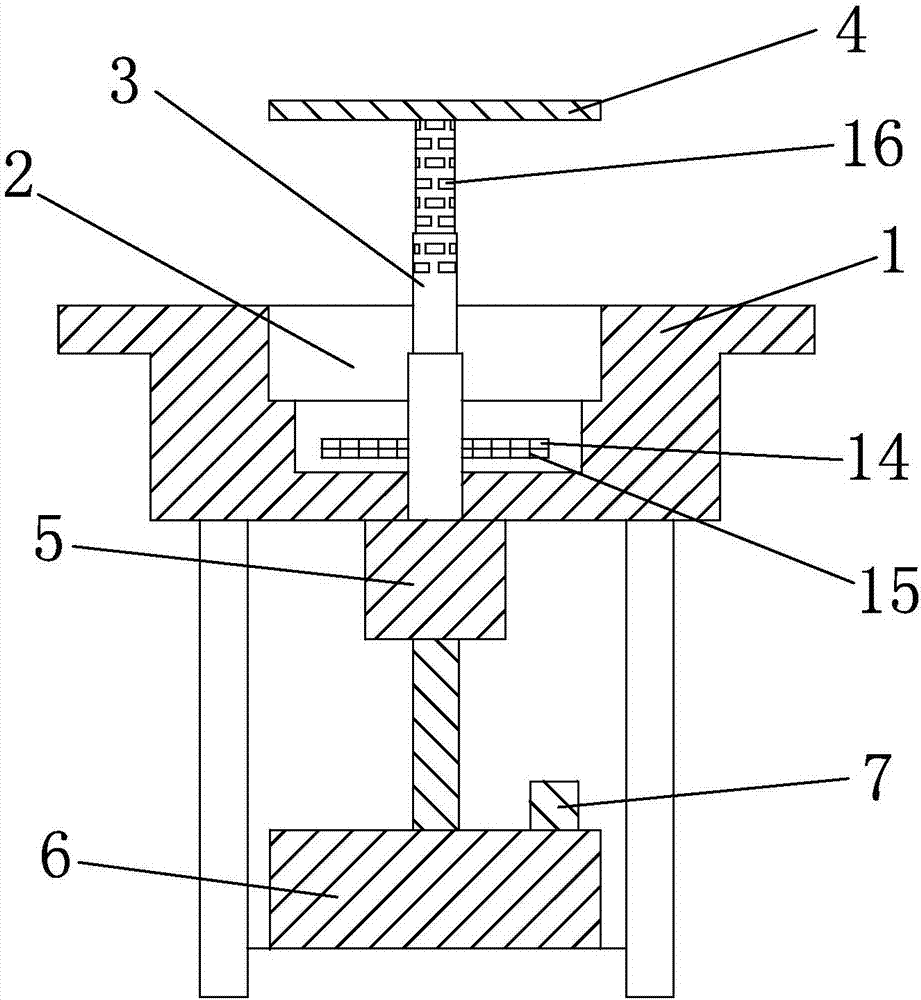

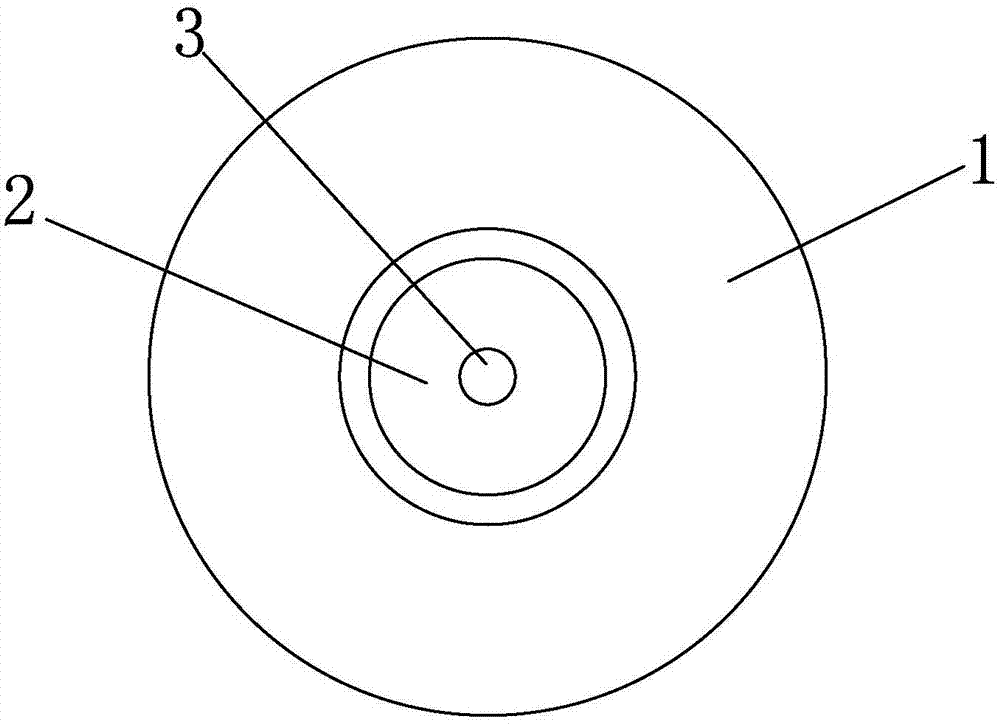

[0029] Such as figure 1 , figure 2 As shown in the figure, a fire boiler with intermediate suction and removal of oil fume is characterized in that it includes a furnace body 1, and a concave cavity 2 is provided on the furnace body 1, and a heating device is provided in the concave cavity 2. The heating device is provided with a chafing dish body 12, and the middle part of the concave cavity 2 is provided with a smoke conduit 3, and the top of the smoke conduit 3 is connected with a smoke collection hood 4, and the smoke conduit 3 is connected from the chafing dish body 12 to the smoke collection hood. 4 is provided with a smoking hole 16, the other end of the smoke duct 3 is connected to the exhaust fan 5, and the output end of the exhaust fan 5 is connected to the oil fume purification box 6, and the oil fume purification box 6 is connected to the exhaust output pipe 7, A chafing dish body 12 is arranged in the concave cavity 2 , and an oil fume purification conduit is ar...

Embodiment 2

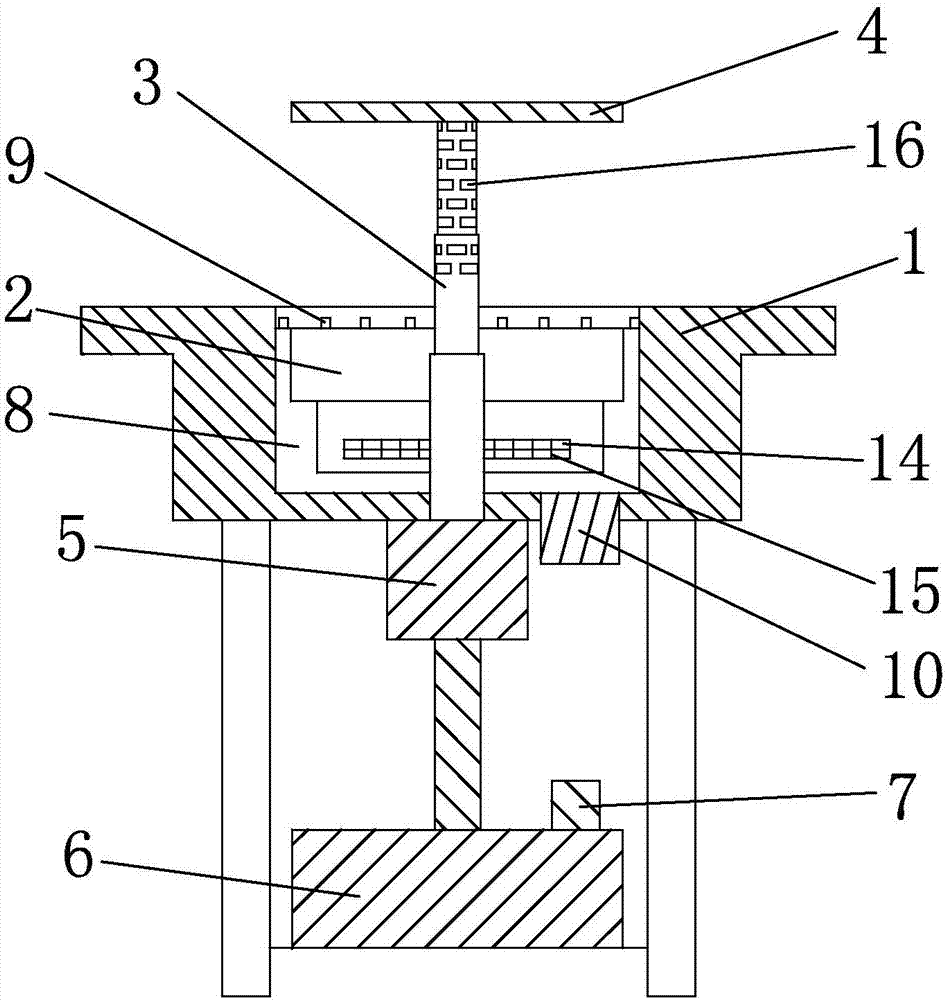

[0033] Such as image 3 and Figure 4 As shown, on the basis of Embodiment 1, an air pressurized chamber 8 is provided between the furnace body 1 and the concave cavity 2, and a plurality of air pressurized chambers 8 are provided on the mouth of the concave cavity 2 to communicate with the air pressurized chamber 8. Compressed air is sprayed vertically upwards to form the air nozzle 9 of the wind screen. The air pressurized chamber 8 is connected with an air compressor 10, which compresses the air and draws it into the air pressurized chamber 8. The compressed air passes through the air nozzle 9 Spray vertically outward at the mouth of the cavity 2, so that the mouth of the cavity 2 forms a wind screen, which can better concentrate the oil fume, prevent the oil fume from spreading outward, and improve the effect of oil fume suction and removal.

Embodiment 3

[0035] Such as Figure 5 As shown, on the basis of Embodiment 2, a return air pipe 11 is connected between the air inlet of the air compressor 10 and the exhaust output pipe 7, so that the air after purifying oil fume enters the air compressor 10, and the compressed air Enter the air pressurization chamber 8 and spray it vertically upward from the air nozzle 9 to form a wind screen, so that most of the purified air re-enters the oil fume purification system for multiple purifications, further reducing the emission of oil fume.

[0036] In Embodiments 1, 2, and 3, the inner wall of the cavity 2 is provided with a vent 14 for replenishing air to the cavity 2 and realizing heat dissipation, and the vent 14 is provided with a tuyere grid 15 to realize the ventilation in the cavity 2. Air replenishment and heat dissipation during the cooking process, the vent 14 is provided with a vent grid 15 to prevent foreign objects from entering the cavity 2 through the vent 14 .

[0037] A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com